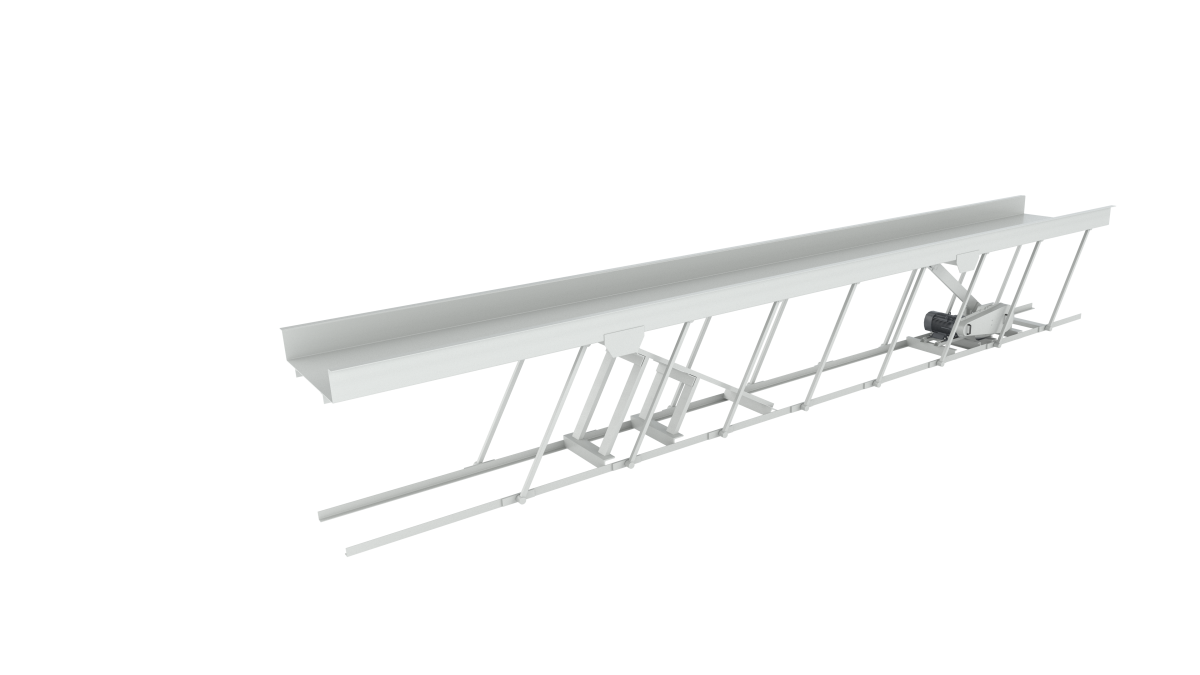

VVR - Vibrating conveyor

Vibrating conveyor are suitable for feeding of drum chipper or also for discharge of bulk materialVibration conveyors feed residual wood to the drum chippers in sawmills. They can also be used for the transport of bulk materials such als fuels (wood chips) in a boiler charging system. If required, we can equip the systems with contaminant detection and an integrated screening zone. Vibration conveyors compensate for volume fluctiations in the feeding and feed the material evenly and continuously to the downstream process.

The highlights of the vibrating conveyors

Vecoplan vibrating conveyors collect residual wood parts in sawing lines, e.g. splinters and board cuttings, and feed them continuously and evenly to the shredder. Volume fluctuations in the feed are compensated. Optionally, fine particles or excess lengths can be separated from fuels via integrated screening zones. An impurity detection and sorting system can also be installed without any problems.

Advantages at a glance

- High conveying capacity

- Low-maintenance continuous operation

- Easy and quick to clean

- Gentle and even conveying

- Solid construction

Which model suits your needs?

| Specification |

|

|

|

|

|

|

|---|---|---|---|---|---|---|

| Motor power | max. 5,5 kW | max. 5,5 kW | max. 7,5 kW | max. 7,5 kW | max. 11 kW | max. 15 kW |

| Weight | - | - | - | - | - | - |

| Conveying capacity volume | 40 m³/h | 70 m³/h | 110 m³/h | 125 m³/h | 150 m³/h | 220 m³/h |

| Total length | 28 m | 26 m | 24 m | 24 m | 20 m | 18 m |

| Clear width | 350-750 mm | 450-950 mm | 450-1,250 mm | 550-1,50 mm | 550-1,250 mm | 650-1,450 mm |

| Maximum inclination | 3 ° | 3 ° | 3 ° | 3 ° | 3 ° | 3 ° |