Our developments at a glance -

an impressive proof of our innovative strength

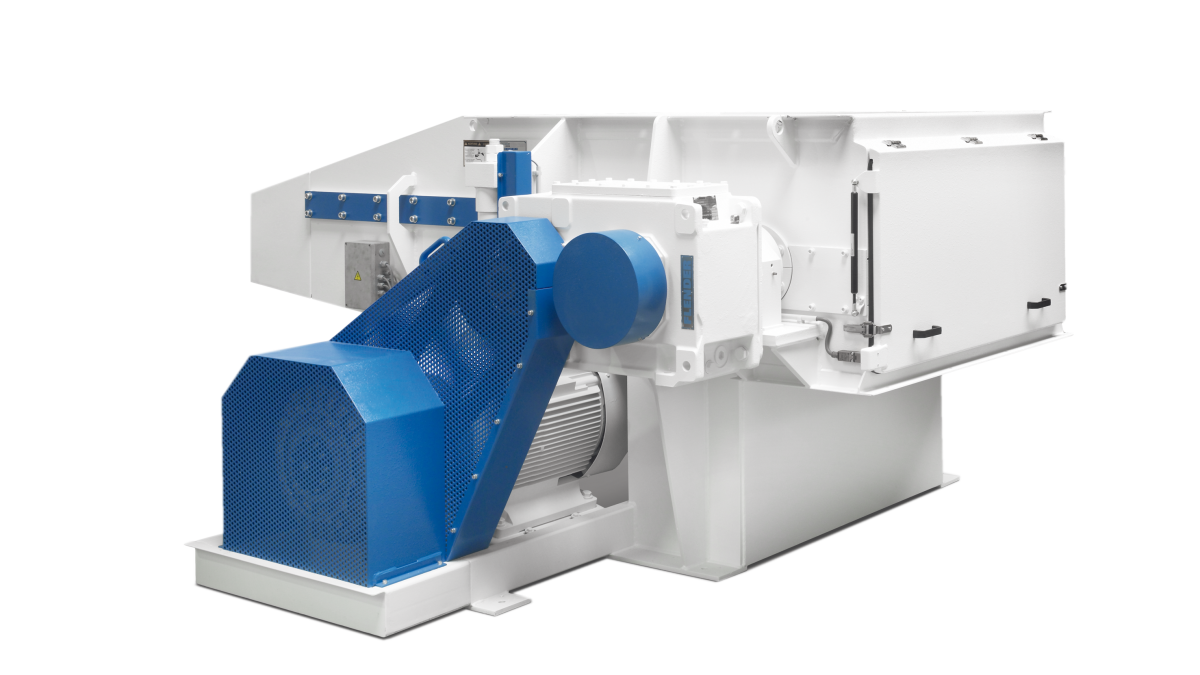

MR - Highly efficient dry cleaning systems

Genuine plastics recyclings is experiencing ever-increasing momentum.

Due to the rising demands on the quality of plastic recyclates, Vecoplan offers a cleaning concept that differs from established technologies and leverages potential for saving water and energy.

VTH 600-1050 BT - the first biomass chipper with HiTorc power

Vecoplan is equipping a chipper with the innovative HiTorc drive for the first time. Compared with conventional drives, this can save up to 40% energy.

VVB – The primary wood crusher

The new Vecoplan primary wood crusher is the efficient and economical solution for producing crushed and shredded material for energy recovery..

Resource-saving and genuine recycling in the newly opened Cleanic

Vecoplan brings a 470 m² demonstration and test centre with integrated water and alkali treatment for cleaning polyolefins to the market. There, dry-mechanical pre-cleaning is combined with wet-mechanical cleaning technology.

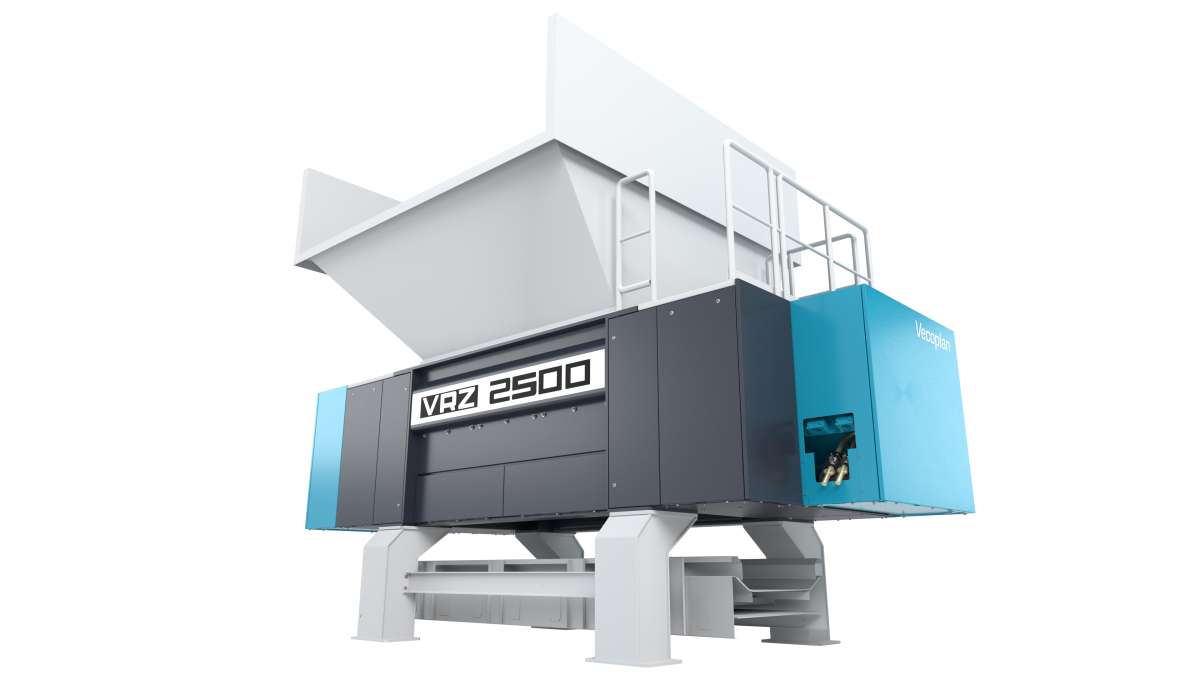

VAZ 2000L6 - the matamorphosis of the waste shredder

Vecoplan has completely redesigned the proven and widely used VAZ waste shredder, giving it improved technology, new features and a modern industrial design.

VPC - primary crusher for large-volume and bulky wood components

The Vecoplan two-shaft primary crusher VPC is used for the primary crushing of large-volume and bulky components, enabling a 50% increase in throughput.

VRZ - a powerful and energy-efficient and energy-efficient waste shredder

With its robust twin-shaft rotor system with tearing process the VRZ is ideally suited to efficiently reduce different inhomogeneous waste to a sortable shape and size efficiently.

VSC - Performance, availability and process stability

With the digitalisation concept VSC ,,Vecoplan smart centre", the customer can establish a network of the machine and thus has even external access, can analyses and access important documents/information.

VIZ - infinite plastic shredding

Plastics recycling is increasingly becoming the focus of our time - more and more and increasingly different types of plastics have to be processed for this purpose. The VIZ meets these requirements thanks to its special flexibility in the drive and in the cutting geometry.

VHZ 1300 - energy-efficent wood shredding

Vecoplan has expanded the VHZ series by the stronger VHZ in the industrial design. The big brother VHZ 1600 follows shortly after. Larger craft businesses and wood processing companies can now efficiently shred hard and solid waste, chipboard , bark and cardboard.

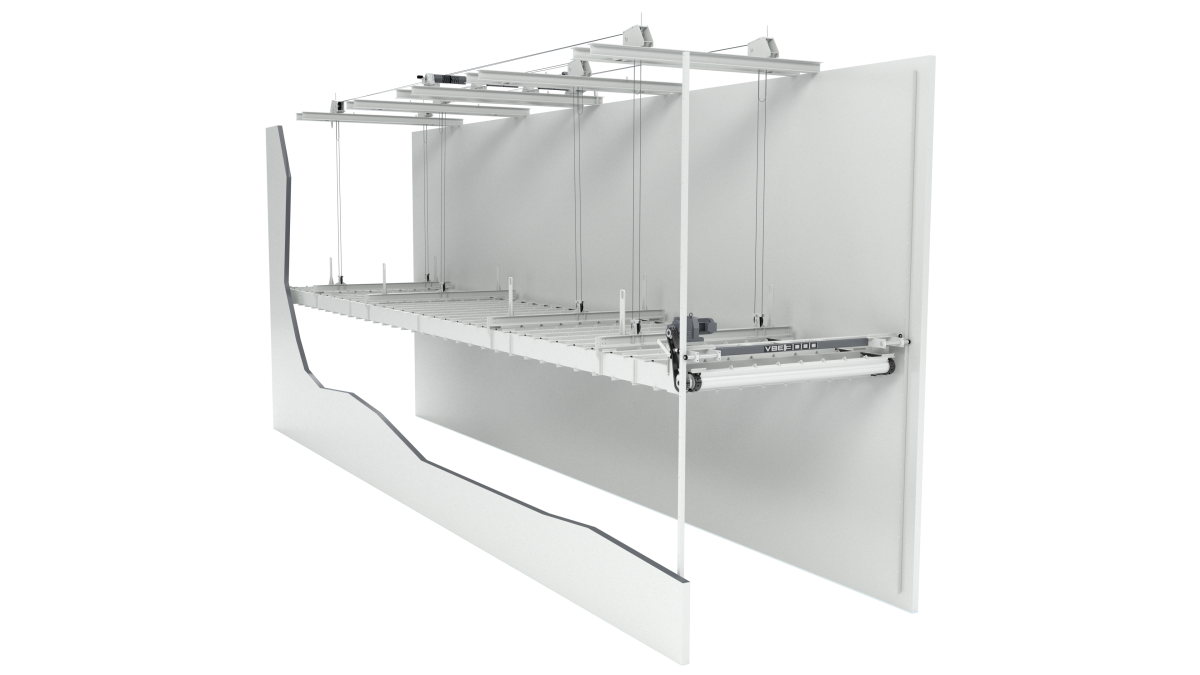

VEZ 3200 - single-stage shredding in the field of RDF

First machine in the new industrial design - extremely powerful as a pre-shredder, it can also be used for single-stage shredding.

Introduction Corporate Industrial Design

Goal: clear differentiation of the Vecoplan shredders from the competition and strengthening the position of the product leader.

VHZ - New small series for the wood craft

Especially developed for the requirements of small and medium-sized woodworking companies. The big brother VHZ 1600 will follow in 2019 with a new machine design.

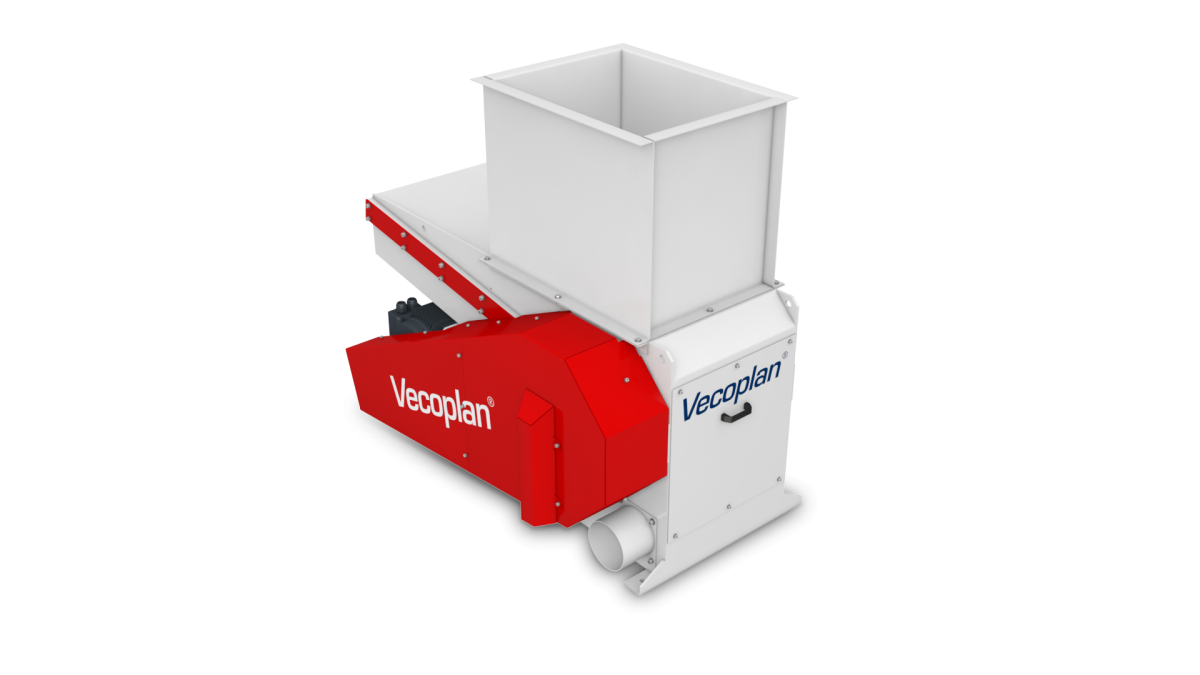

Combined shredder-granulator VD for in-house recycling

Two shredder types in one machine - with this combination the customer saves one process step and can shred difficult and large-volume production waste in one step.

Bag opener VSA

With firmly welded beaters instead of cutting crowns, the special rotor in the VSA does not shred but tears up the waste bags for post consumer recycling.

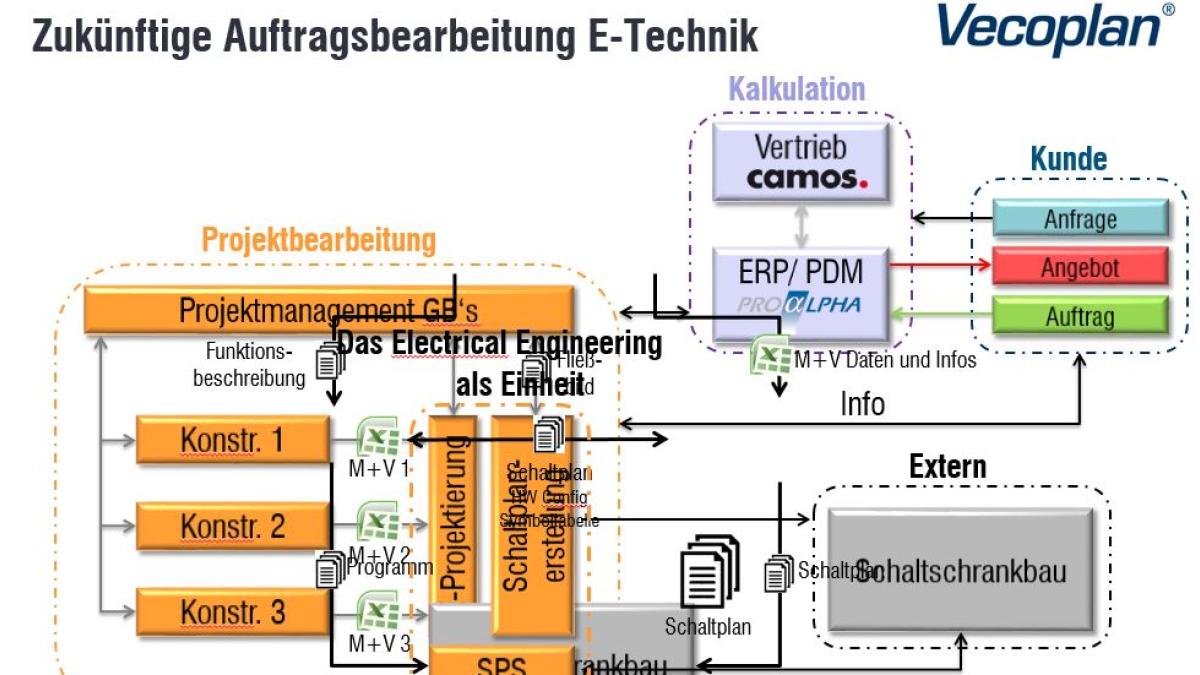

Electrical engineering know-how is bundled

Electrical engineering is complemented by the circuit diagram design and programming

V-ECO - the high-performer in plastics recycling

For plastics of various types, the market demanded a shredder that also offers high throughput combined with energy-efficient drive - the V-ECO with ESC drive meets these requirements and is becoming the best plastic film shredder in recycling.

VEZ Single-shaft shredder

The VEBS is being revised - it will be followed by the VEZ, which is used very successfully as a re-shredder in refuse-derived fuel processing thanks to its robust design and functional handling of impurities.

Digital data destruction with the VDS 800

The change to digital data protection requires a secure shredder for the destruction of data carriers and this for different particle sizes according to the different security levels.

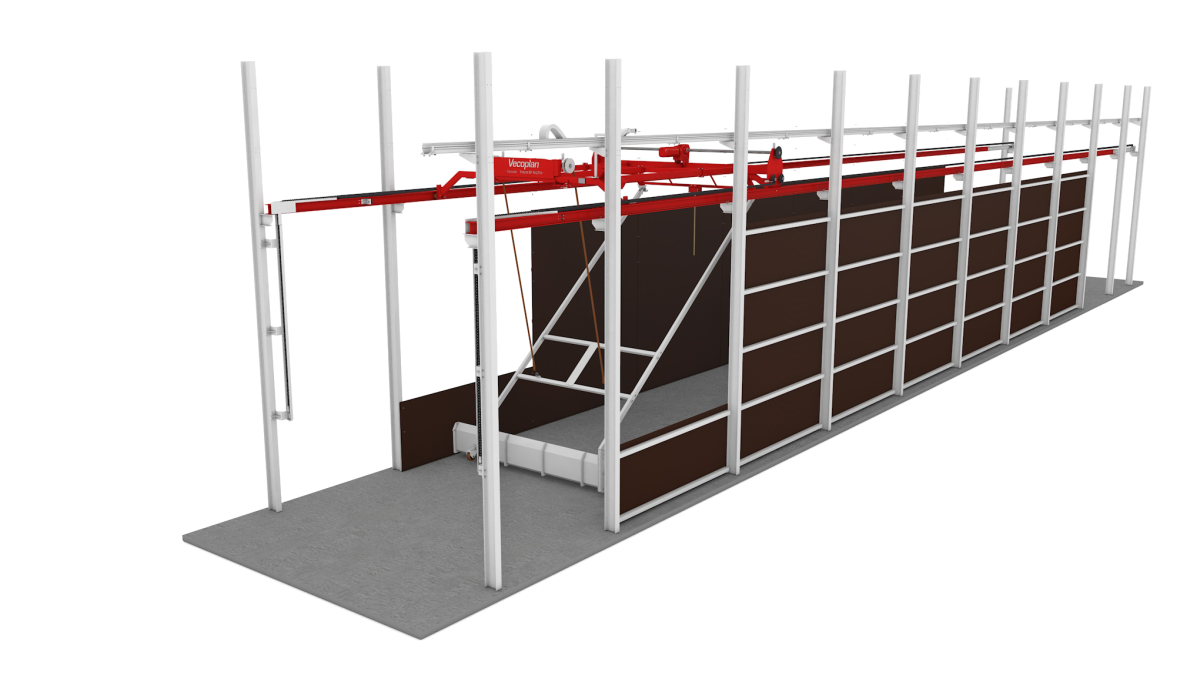

The toploader complements storage technology spectrum

A semi-automatic storage system: The storage box is filled with bulk materials via wheel loader, truck etc., and emptying is then fully automatic.

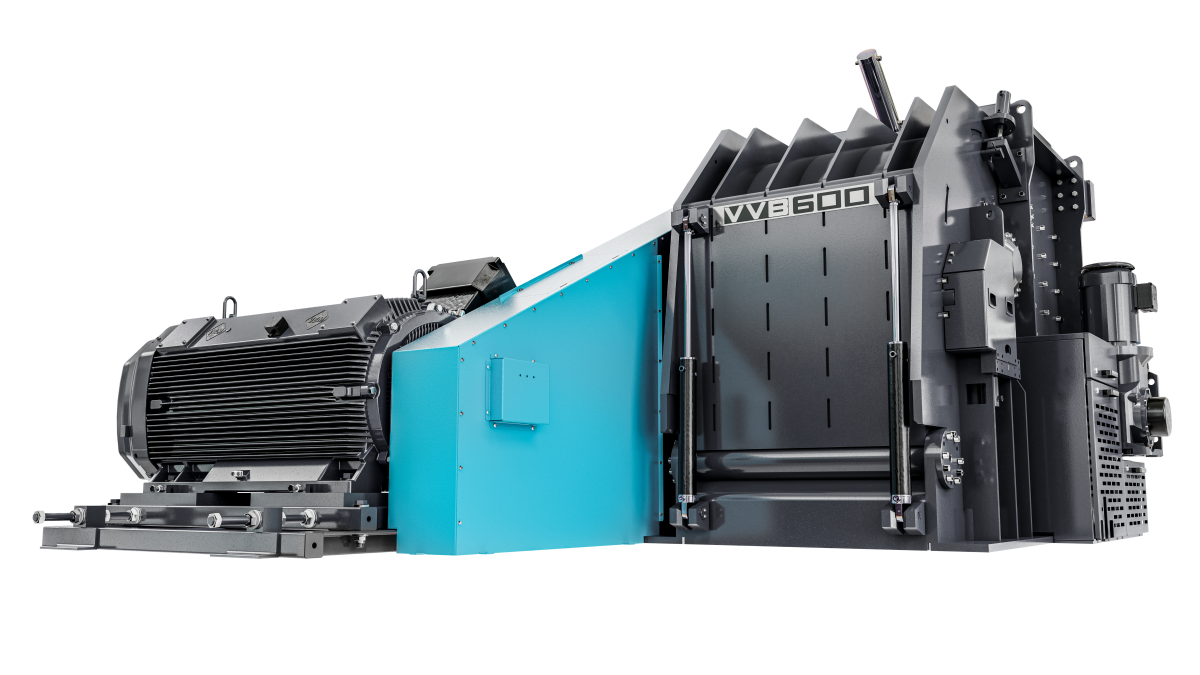

EBS high performance shredder

Market launch of the VEBS - a shredder specially designed for for the production of refuse derived fuels used in the cement and power plant industry

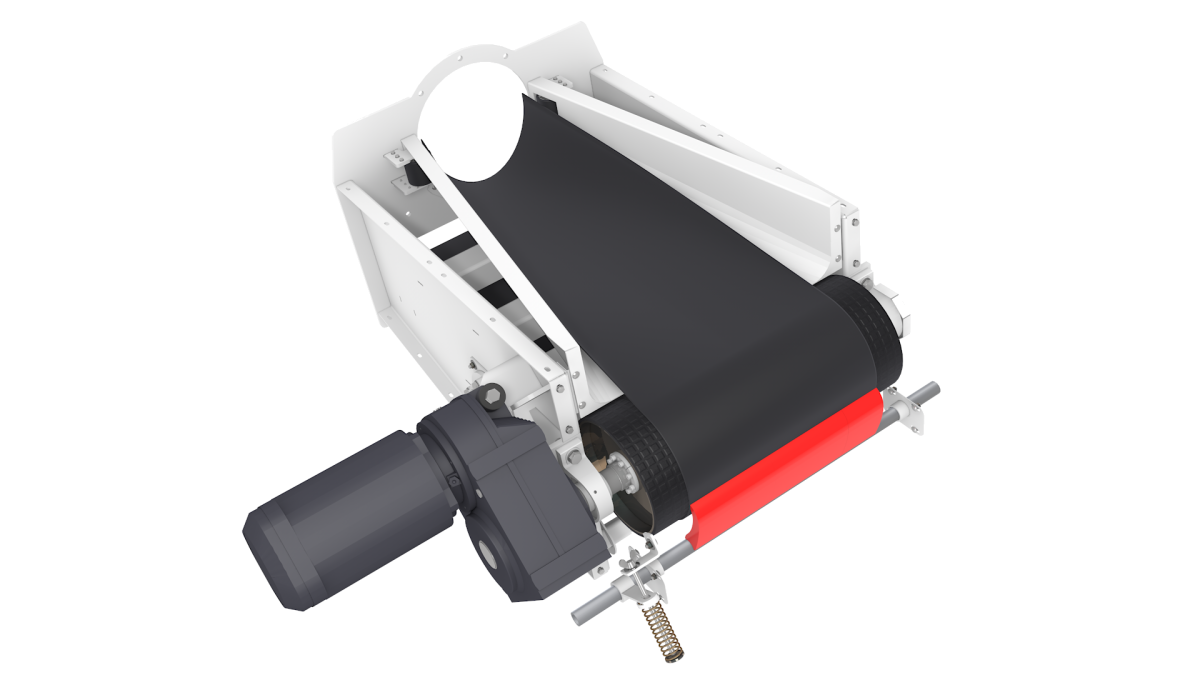

Pipe conveyor VecoBELT (VRF)

Conveys a large quantity of bulk materials over very long distances in a dust-tight manner and with a relatively very low pneumatic drive power.

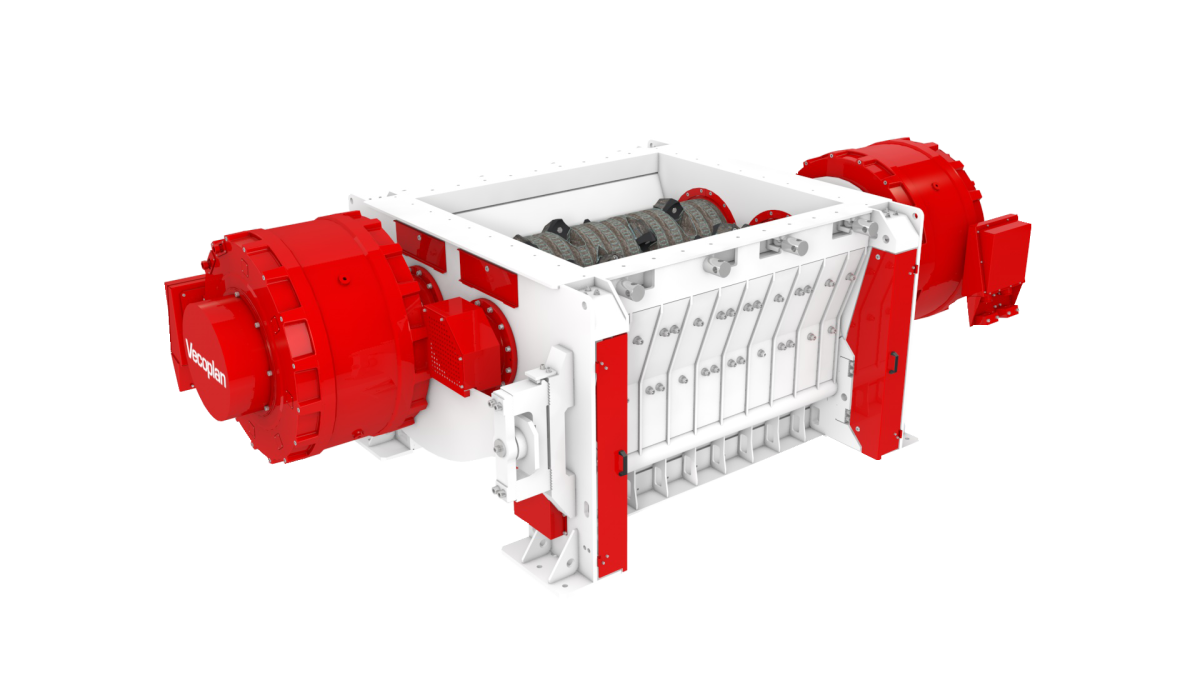

Double-shaft primary crusher with HiTorc

The world's first pre-shredder with purely electric drive based on the Hurricane VVZ achieves outstanding results in the pre-shredding of municipal and industrial - this is due to the extraordinarily high torques and the extremely shock-resistant operating mode

Impurity detection for shredding machines

Universal device for the detection of contaminants hazardous to the machine in all Vecoplan shredders

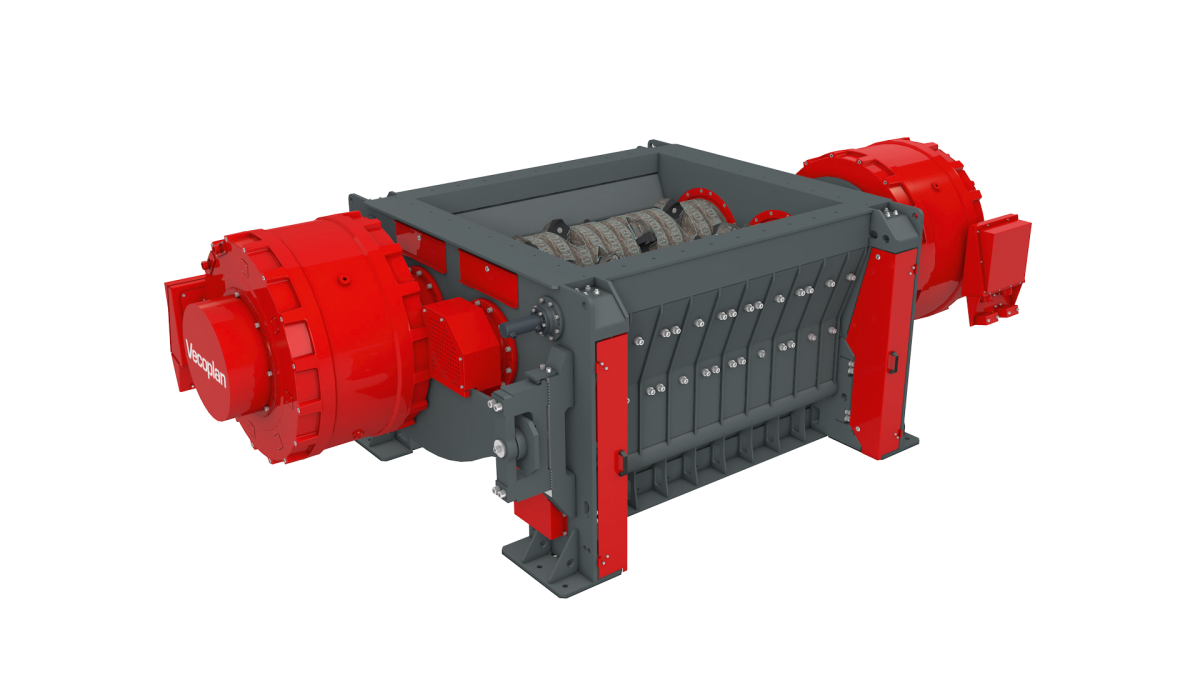

High-performance shredder for waste

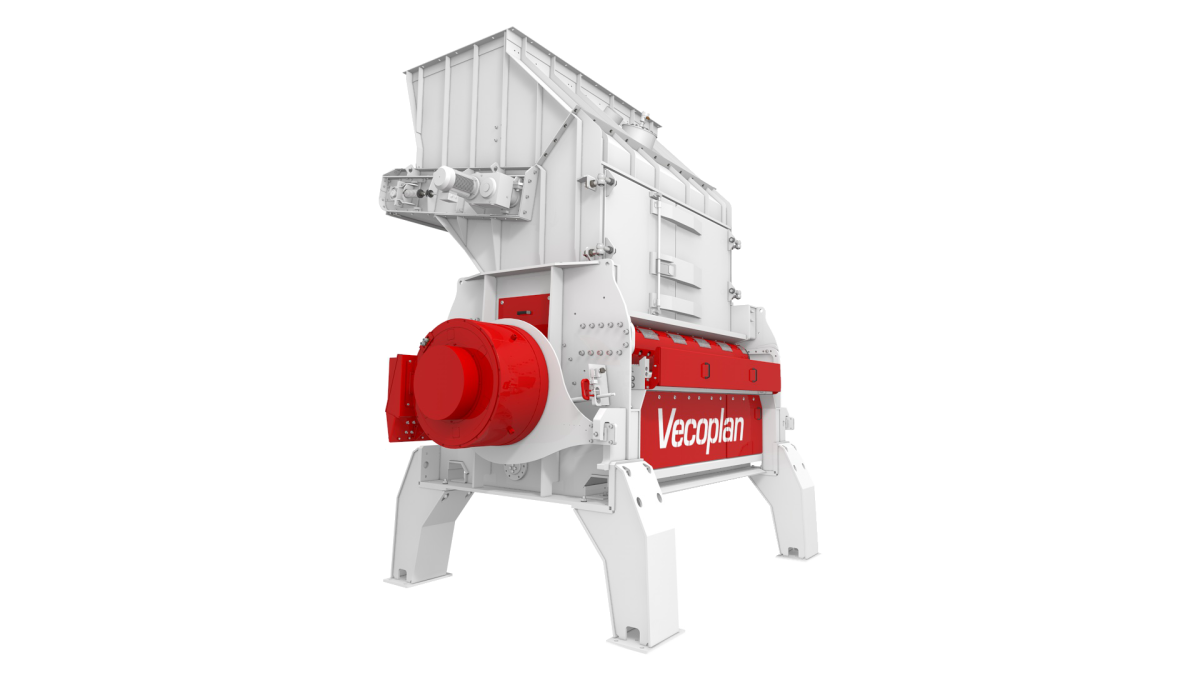

Especially for the industrial processing of municipal and industrial waste, the extra strong double-shaft shredder type VVZ Hurricane with a modular machine concept was developed.

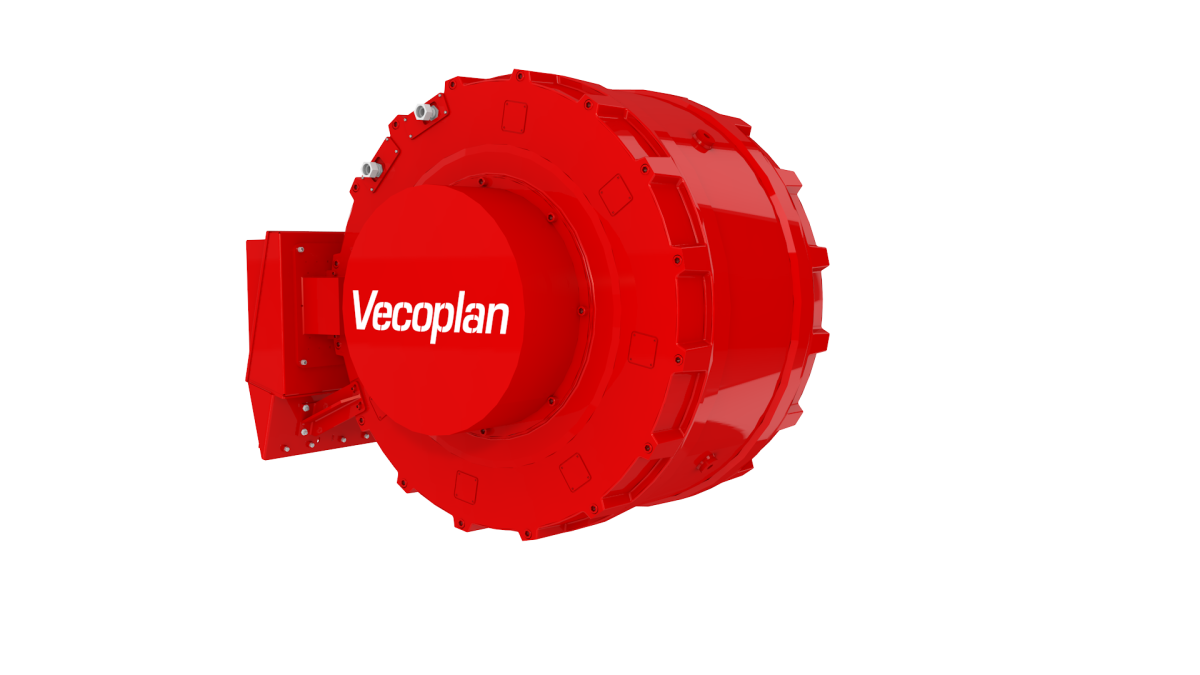

HiTorc direct drive

As an alternative for the maintenance-intensive mechanical drives, an energy-efficient and highly functional direct drive was developed and patented together with Oswald Motoren - the HiTorc has been an outstanding unique selling point of Vecoplan since its market launch.

Single-shaft shredders for mobile data destruction

Adaptation of the proven single shaft-shredder for the special requirements of mobile data destruction in the market - the solution of a compact shredding unit for for integration into a truck was patented.

Cutting unit for tear-resistant films and synthetic fibres

New "F-Rotor" (film & fiber) with patented cutting unit for the shredding of demanding plastic fibres and films.

Double-shaft shredder with "Flipper"

With the pre-shredder VVZ and the subsequent re-shredder VNZ, the first double-shaft shredders are launched on the market - due to the success of the VAZ, they are equipped with the air-suspended counter knife.

Slow running shredder for plastics

Further development of the VAZ for the shredding of all types of plastic residues requires adjustments to the design, the control system and the cutting geometry.

"Flipper" for Single-shaft shredders

Air-suspended counter-knife, which protects the cutting unit and drive components when collecting contaminants, thus ensuring unmatched shredder reliability.

Universal rotor for shredders

Patented development of the U-rotor, which enables universal use of the VAZ and thus lays the foundation for the outstanding success of the shredder.

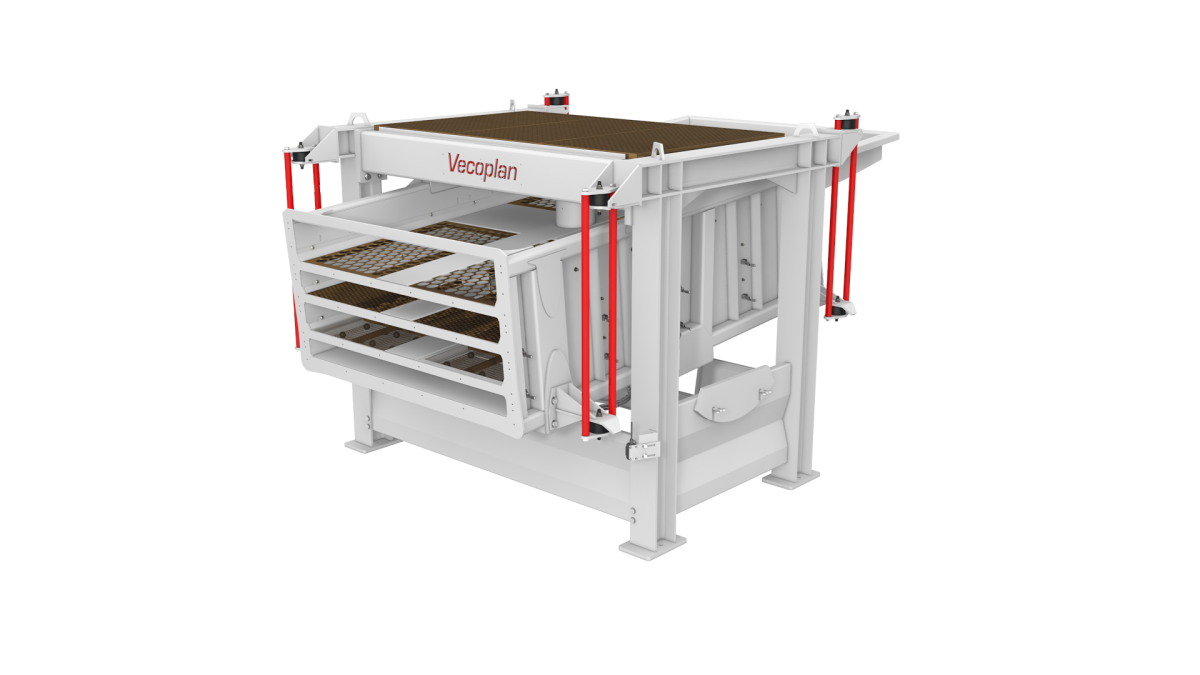

Free-swinging Plansifter System VSS

The drive with unbalanced masses ensures a completely free oscillation of the screen box and thus prevents the transmission of forces and tensions to foundations and buildings.

Single-shaft shredder with storage container VAZ

Development of a shredder for the special applications in in waste wood processing - due to the slow speed of the robust cutting unit, it is less sensitive to impurities than the previous chippers and the integrated storage container ensures longer operating times.

Combined loading and unloading conveyors for silos

Fully automatic system for continuous filling and emptying of rectangular bunkers that revolutionized material handling in sawmills and later also in biomass cogeneration plants.

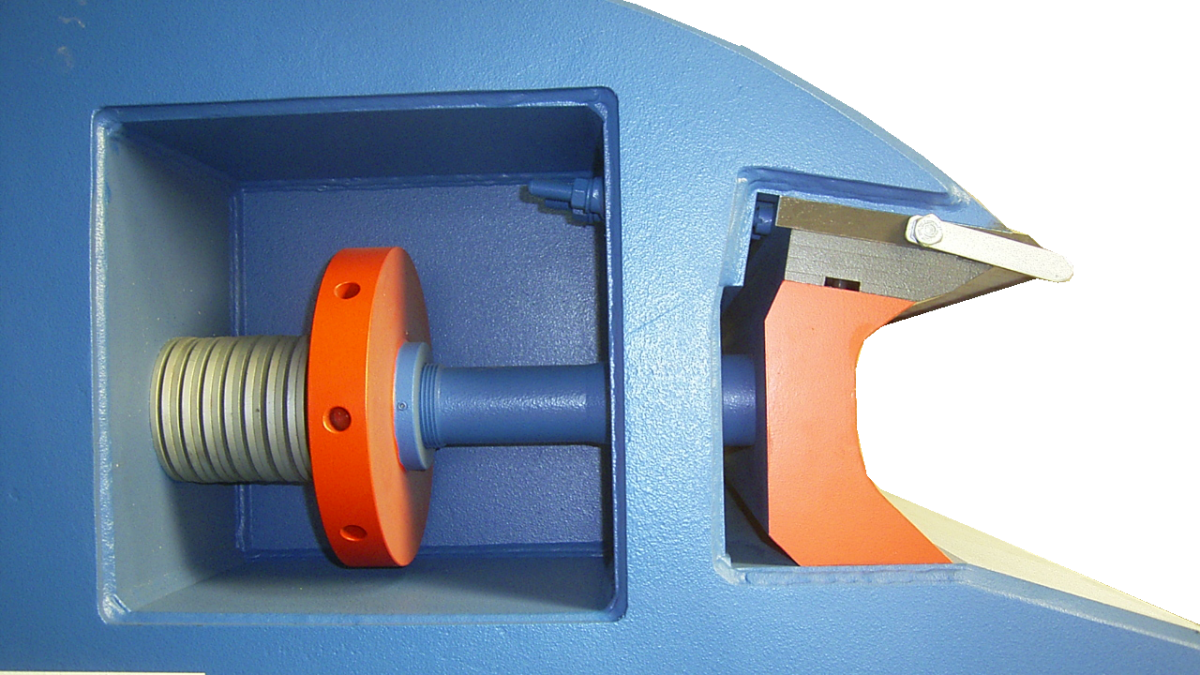

Centrifugalwedge clamping

Solution for a self-tensioning fastening of knives - still one of the safest and most effective methods to prevent knives from tearing loose in high-speed drum chippers.