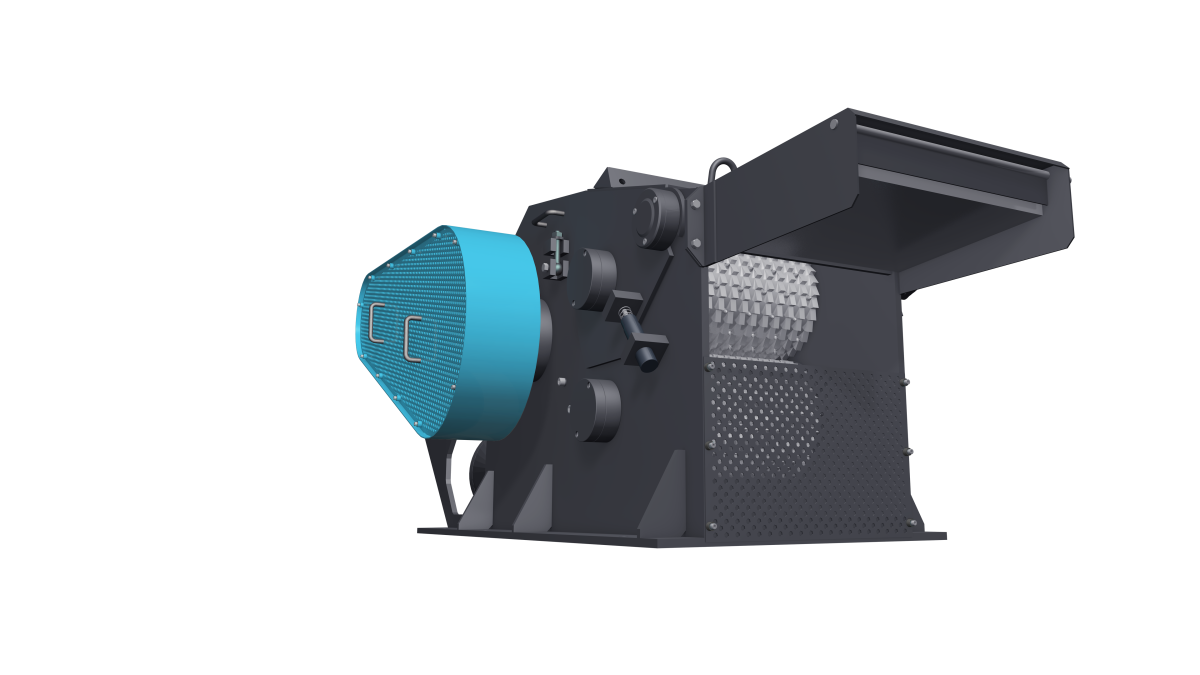

VTH - Drum chipper

The drum chipper for economical production of wood chipsDo you want to produce fuel chips for energy generation, or quality chips for the cellulose industry – extremely economically? Then look no further than our VTH drum chippers. You’ll achieve enormous throughput rates with these drum chippers. These are stationary machines with a horizontal feeding unit. They are equipped with a rotor fitted with chipping knives for shredding round wood for the energy industry or residual wood in sawmills, for example.

VTH - Drum chipper

More flexibility, less downtime –

our powerful drum chippers

The Vecoplan drum chipper VTH is known worldwide in the timber industry for its robustness and durability due to its enormous throughput and wide range of sizes and rotor systems. It is designed to perform a range of tasks, from the production of fuel chips for energy generation through to quality wood chips for the wood pulp industry. In a nutshell, it is used in industrial applications where wood chips are required as the starting material for a subsequent production process. The material is fed horizontally into the drum chippers. Feeding via vibratory conveyor or conveyor belt is possible. Our proven drum chippers are appreciated by our customers from the biomass recycling and the wood processing industry. The versatile Vecoplan drum chippers are exceptionally durable, reliable and powerful thanks to our many years of experience and top development expertise.

Benefit from our

modular and flexible design!

Efficient and flexible - our drum chippers are suitable for any size of operation. The modern design ensures optimum accessibility, while the rotor, screen and counter blade can be individually adapted to your requirements. This gives you an output product of the desired quality and grain size - tailored to your needs.

Your advantages at a glance

- Highest reliability and availability

- Low operating costs

- Maximum throughput

- Consistent output quality

- Low losses due to low fines content

The highlights of the VTH - Drum chipper

In order to achieve a homogeneous end product of high quality, we adapt our drum chippers precisely to specific customer requirements: Depending on the input material, chipper knives or U-rotors with cutting crowns are used.

The material to be processed is fed horizontally into the machine and feeding is possible via vibratory conveyor as well as via a conveyor belt. To achieve a homogeneous result of high quality, we adapt our drum chippers exactly to the specific customer requirements. Depending on the input material, chipper knives or U rotors with cutting crowns are used.Whether for small and medium-sized operations or larger throughput volumes: We offer you economical and efficient drum chipper solutions for the production of wood chips according to the respective application in the required quality and quantity.

Tschopp Holzindustrie relies on waste wood processing from Vecoplan in its new sawmill

Tschopp Holzindustrie AG manufactures quality shuttering panels. The company uses its wood residues for pellet production. The capacities of the plant have been at the limit for years. With a new plant, Tschopp will now triple wood processing in the medium term – and that necessitates high-performance chip disposal. Vecoplan supplied Tschopp with the perfect technology for this task.

Which model suits your needs?

| Specification |

|

|

|

|

|---|---|---|---|---|

| Type of drive | Belt drive | Belt drive | Belt drive | Belt drive |

| Motor power | 18.5 kW | 18.5-30 kW | 37 - 90 (at 50 Hz) kW | 55-160 (at 50 Hz) kW |

| Speed range | 200-1,000 1/min | 200-1,000 1/min | - | - |

| Rotor diameter | 300 mm | 300 mm | 400 mm | 700 mm |

| Weight | - | - | 2,25 - 4,1 to | 4,9 - 9,5 to |

| Dimension (Length) | - | - | 2255 mm | 3090 mm |

| Dimension (Width) | - | - | 1432 - 2320 mm | 1628 - 2516 mm |

| Dimension (Height) | - | - | 1170 mm | 1360 mm |

| Inlet height | 80 mm | 80 mm | 160 mm | 260 mm |

| Inlet width | 350 mm | 350 mm | 478 - 1366 mm | 478 - 1366 mm |