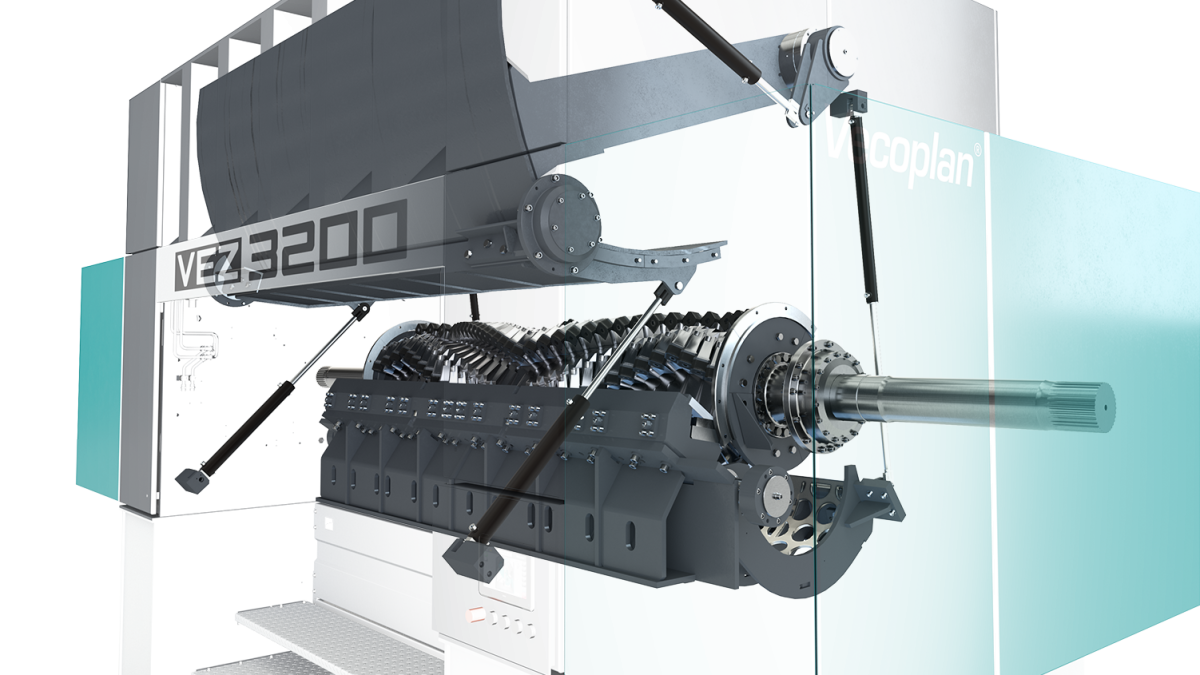

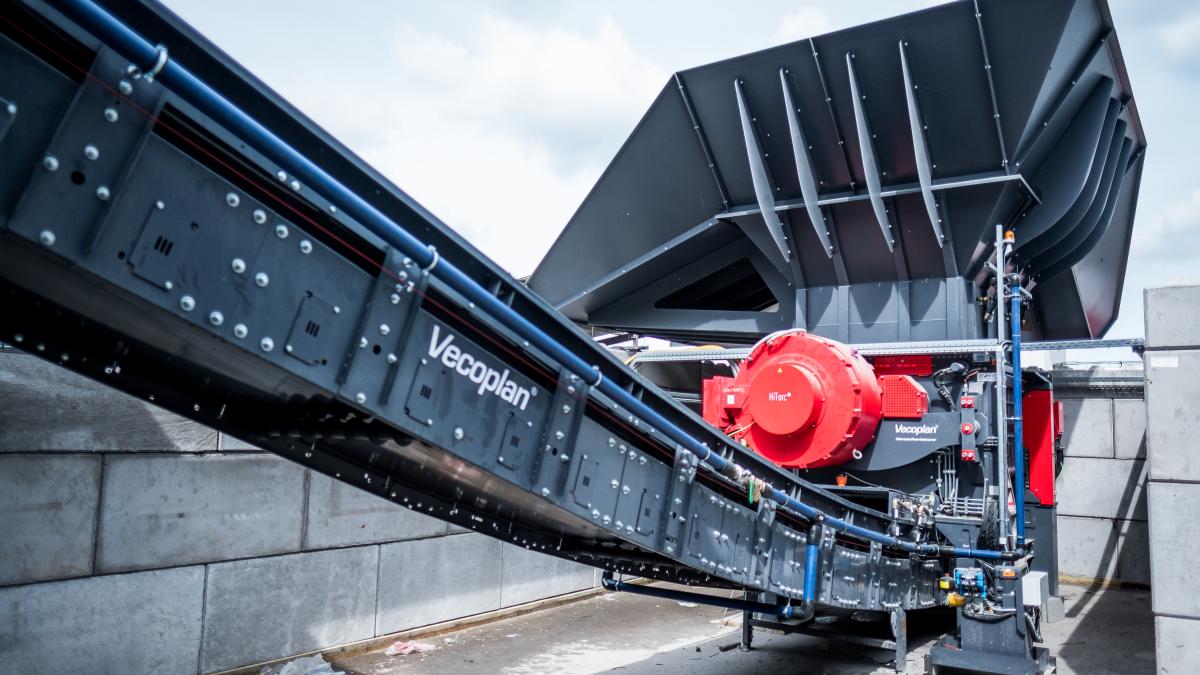

VEZ - RDF shredder (pre-shredding)

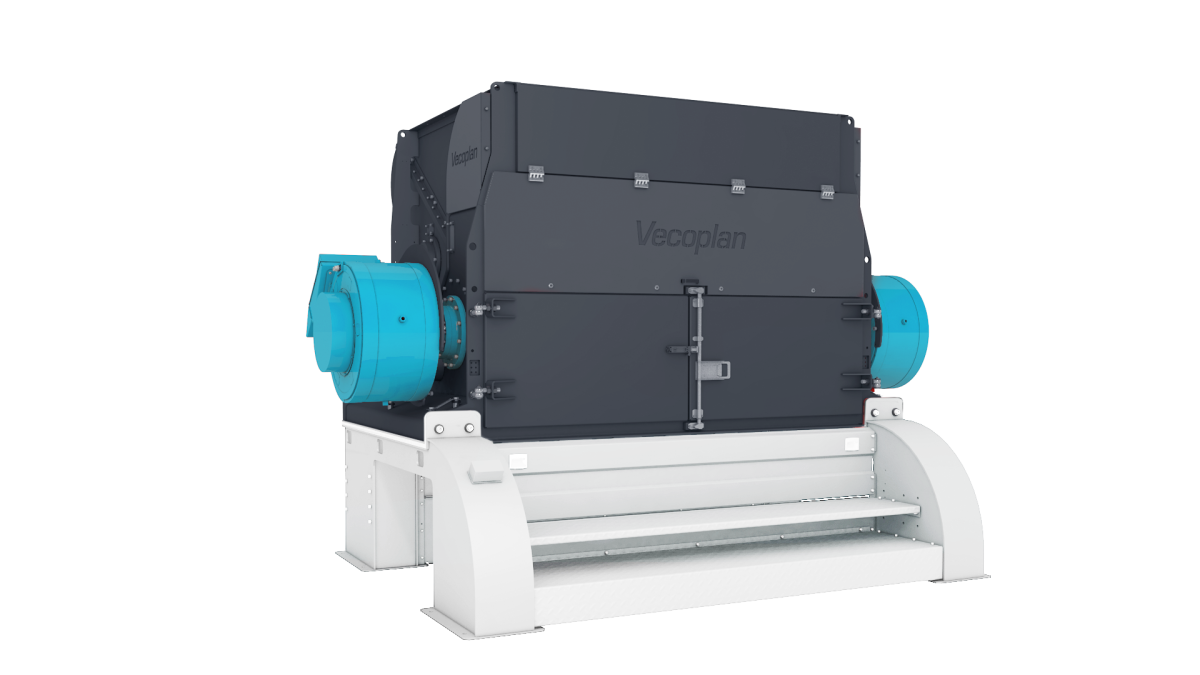

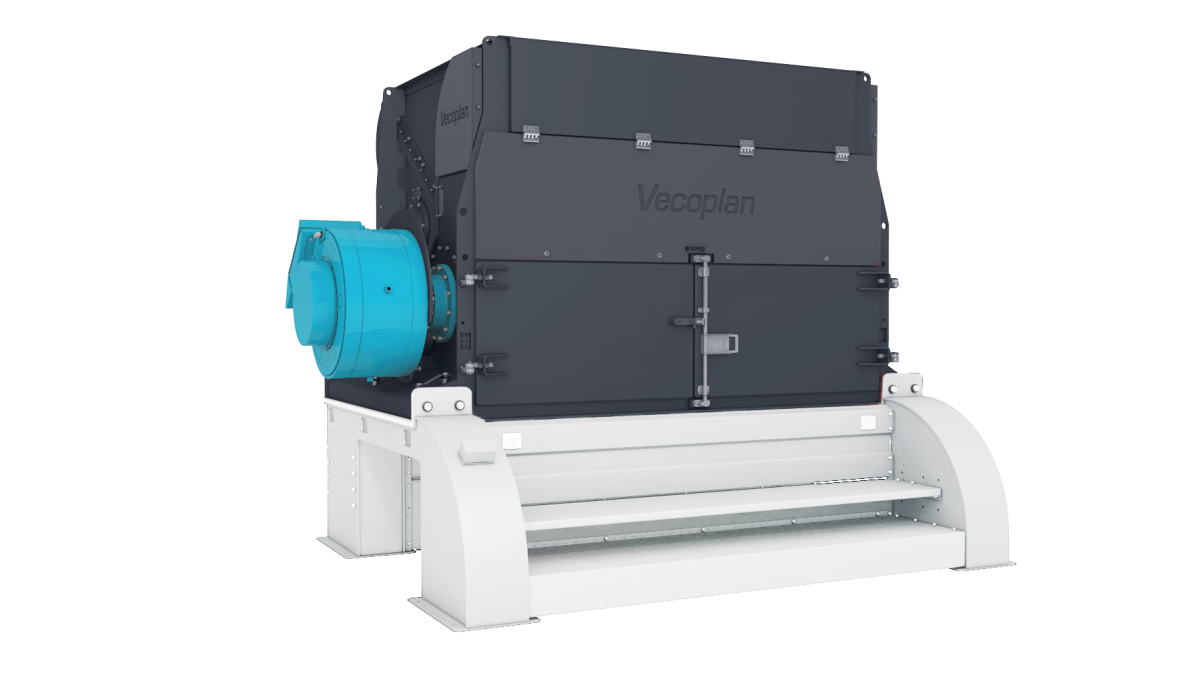

Pre-shredding of a wide variety of input materials for the production of substitute fuelsAlternative fuels recovered from production and sorting residues, packaging material and domestic and commercial waste have proven to be a cost-effective solution for providing energy in cement and power plants. Our VEZ-TV and VEZ-TTV pre-shredders are equipped with one and two HiTorc drives respectively, and these machines can efficiently process a wide range of totally different input materials. You can integrate these two robust shredders into your existing processes and shredding lines or set up a completely new processing system. The result is a totally reliable process with a consistently high output quality.

VEZ - RDF shredder (pre-shredding)

High-performance in RDF processing

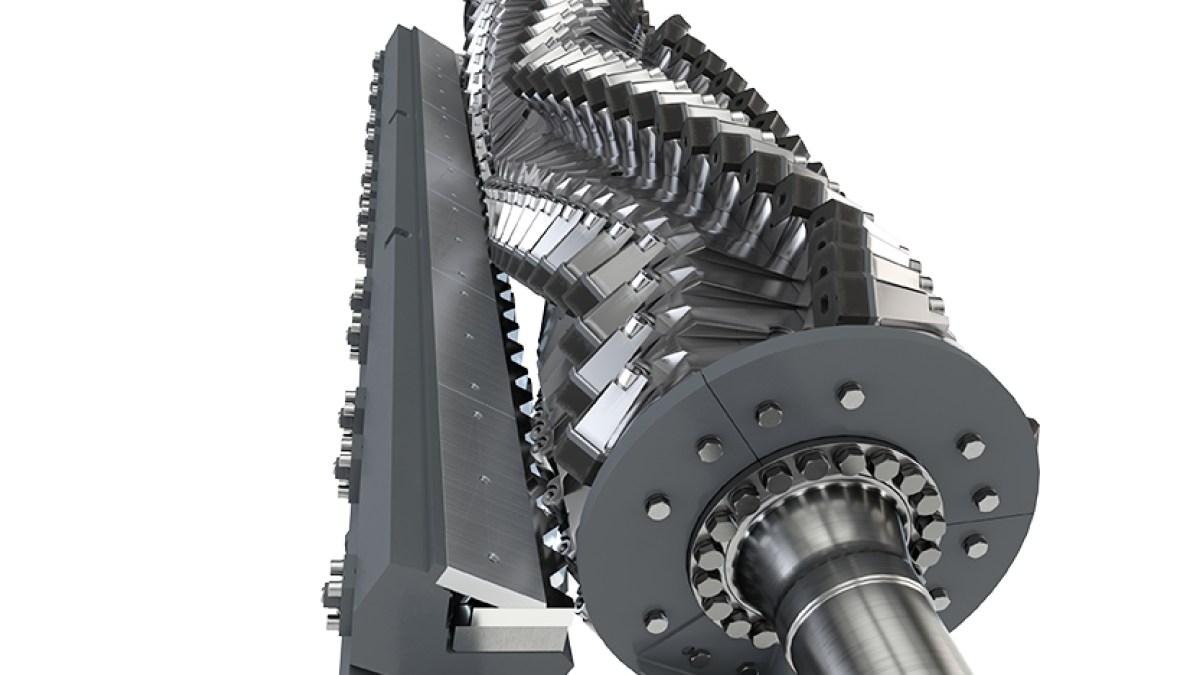

Our VEZ single-shaft shredder use the best Vecoplan technologies. The machines are excellently equipped and benefit from many well thought-out detail solutions in the shredding process. The HiTorc drive and the patented W-Rotor are systems developed by Vecoplan. This enables us to implement unique solutions for you in RDF processing that give you clear competitive advantages.

The highlights of the VEZ - RDF shredder

Extremely flexible and reliable - Pure shredder power

The machine housing consists of an extremely robust construction with optimal machine geometry. It forms the basis for efficient and trouble-free operation. Interchangeable screen linings in a wide range of variations enable use both in primary shredding and in single-stage shredding of refuse-derived fuels. Very good maintenance accessibility and possible removal of impurities are ergonomically possible through a large maintenance door and a hydraulic bottom flap.

Your advantages at a glance

- Robust and durable design for extreme conditions

- Unlimited flexibility through various configuration options

- Highest reliability and availability

- Cost minimisation through energy efficiency

- Ergonomic machine design for optimum maintenance and service accessibility

- Best added value through consistently high and homogeneous output

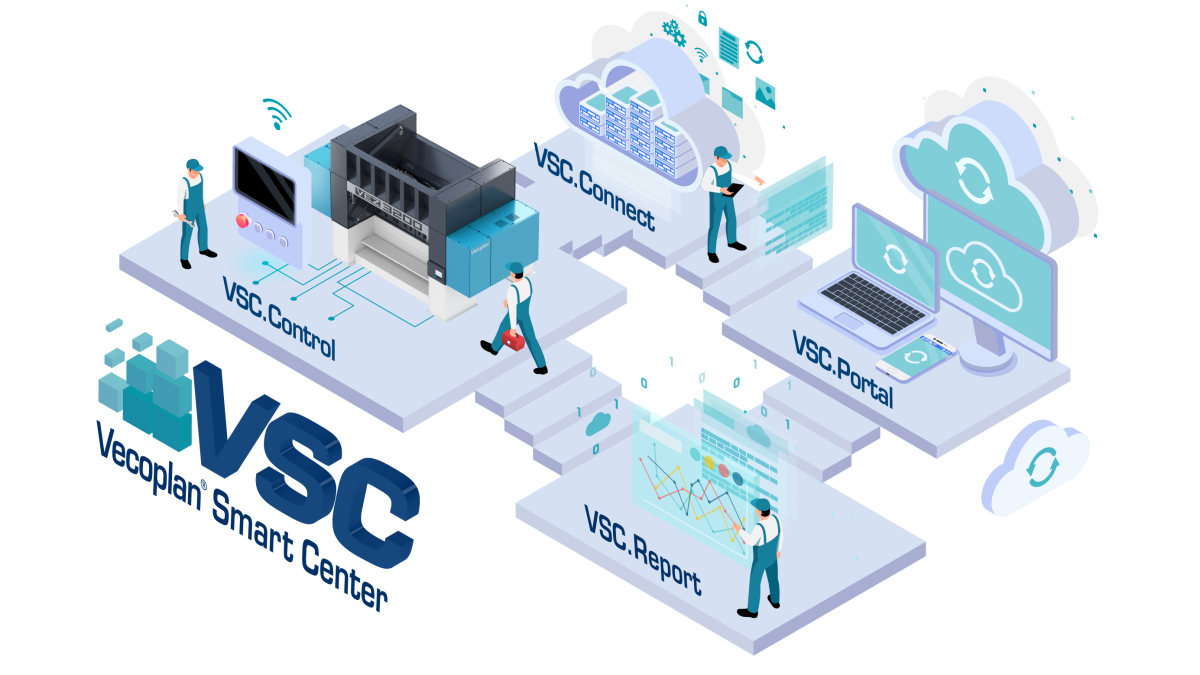

- Intuitive machine operation via VSC. Control

- Online support and optimisation via the Vecoplan Smart Center

The power pack among the single-shaft pre shredders

The Vecoplan VEZ offers maximum efficiency and profitability in RDF processing. In RDF processing, it is also used as a pre-shredder to produce sortable and conveyable material from production residues with a particle size of less than 250 millimetres.

Which model suits your needs?

| Specification |

|

|

|

|

|

|---|---|---|---|---|---|

| Type of drive | Direct drive HiTorc | Direct drive HiTorc | Direct drive HiTorc | Direct drive HiTorc | Direct drive HiTorc |

| Motor power | 2 x 247 kW | 155 kW | 247 kW | 2 x 155 kW | 355 kW |

| Speed range | 150 - 420 1/min | 20 - 100 1/min | 150 - 420 1/min | 20 - 100 1/min | 20-120 1/min |

| Rotor length | 2,500 mm | 2,500 mm | 2,500 mm | 3,200 mm | 3,300 mm |

| Rotor diameter | 640 mm | 800 mm | 640 mm | 800 mm | 800 mm |

| Weight | 22 to | 28 to | 20 to | 35 to | 57 to |

| Dimension (Length) | 2,960 mm | 2,770 mm | 2,960 mm | 2,770 mm | 1461 mm |

| Dimension (Width) | 4,940 mm | 5,790 mm | 4,300 mm | 6,490 mm | 2900 mm |

| Dimension (Height) | 2,300 mm | 2,600 mm | 2,300 mm | 2,600 mm | 3428 mm |

| Inlet height | - | - | - | - | 3330 mm |

| Inlet width | - | - | - | - | 1940 mm |

| Throughput capacity | - | - | - | - | 50 to/h |