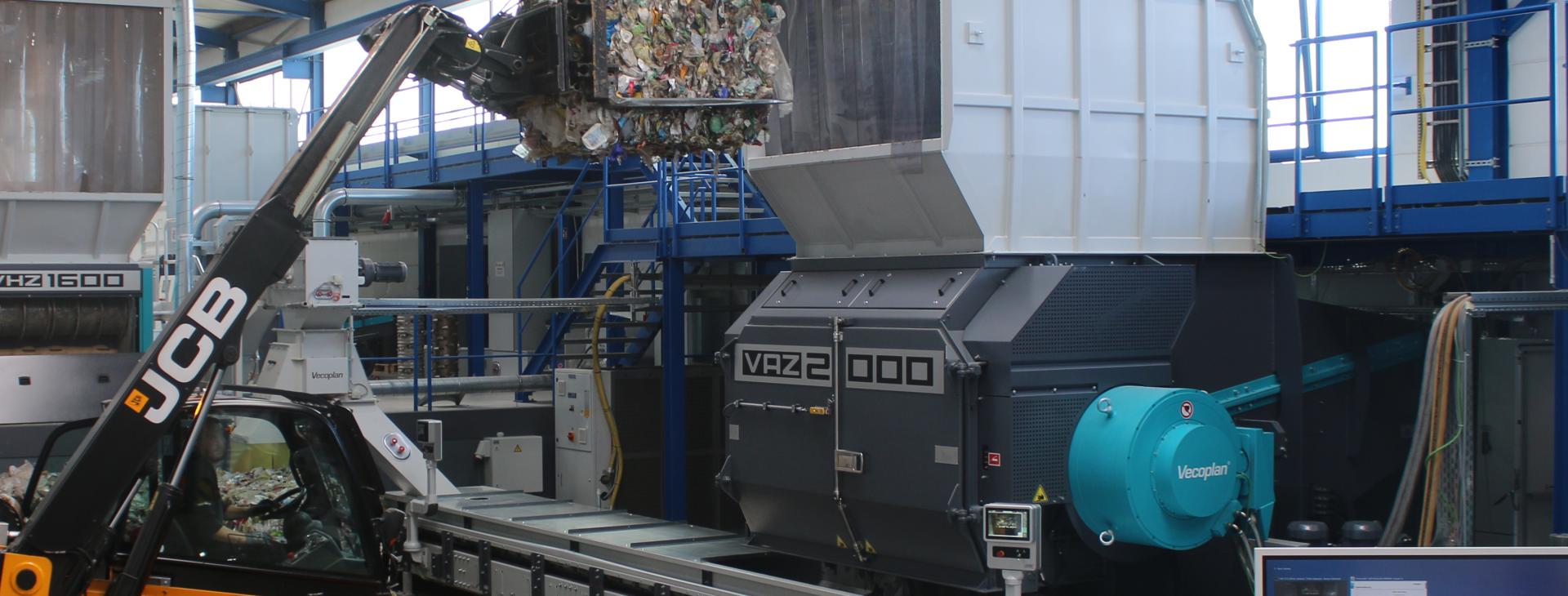

VAZ Shredder for Reusable Material – Packaging Opening & Dissolving Applications

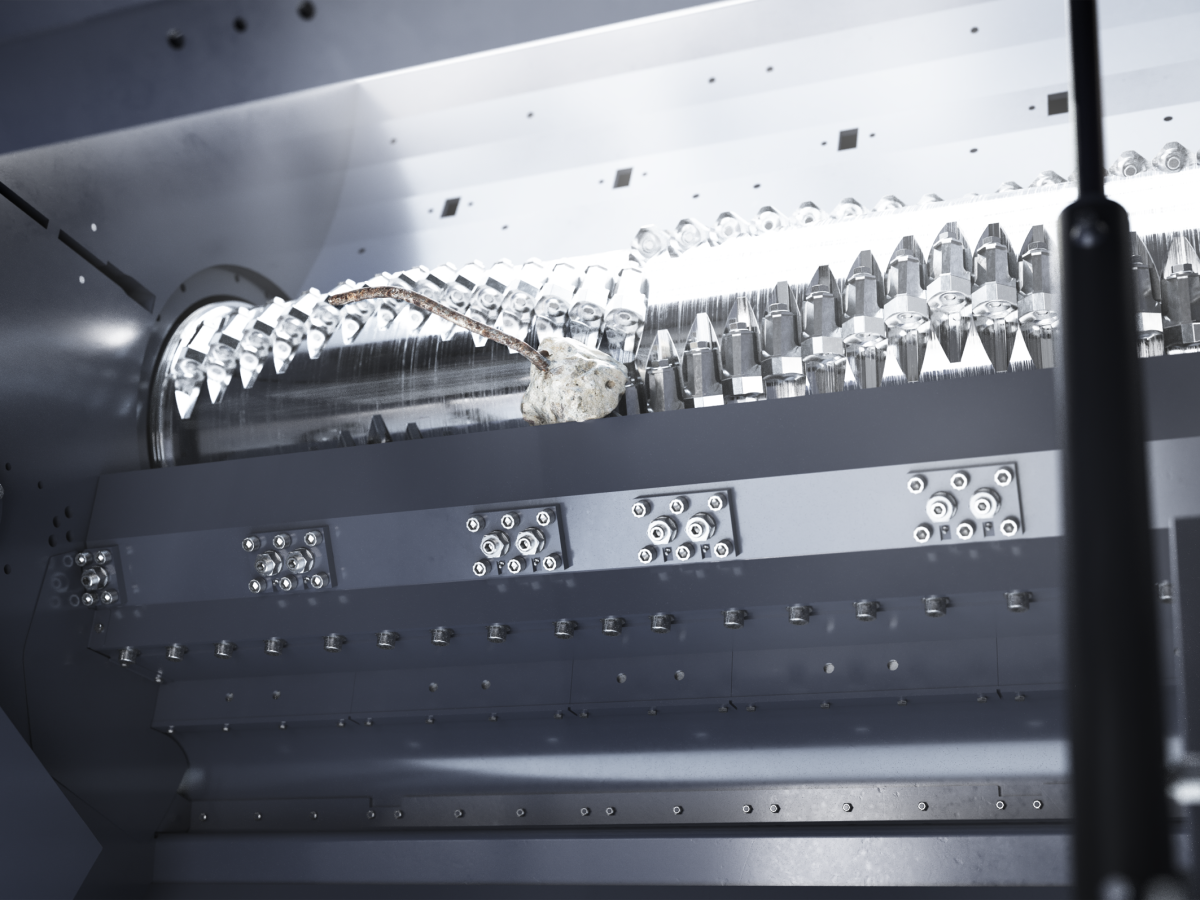

Problem-free shredding even of complete balesThe VAZ shredder for reusable materials is generally used for single-stage shredding or pre- or re-shredding of a wide variety of input materials. The larger types of this proven series are even suitable for those applications where complete packages have to be broken up or opened and crushed. For example, you can feed the baled material directly through the hopper. The shredders handle this task without any problems.

VAZ - Shredder for reusable material

The generalist –

Universally applicable for

a wide range of materials

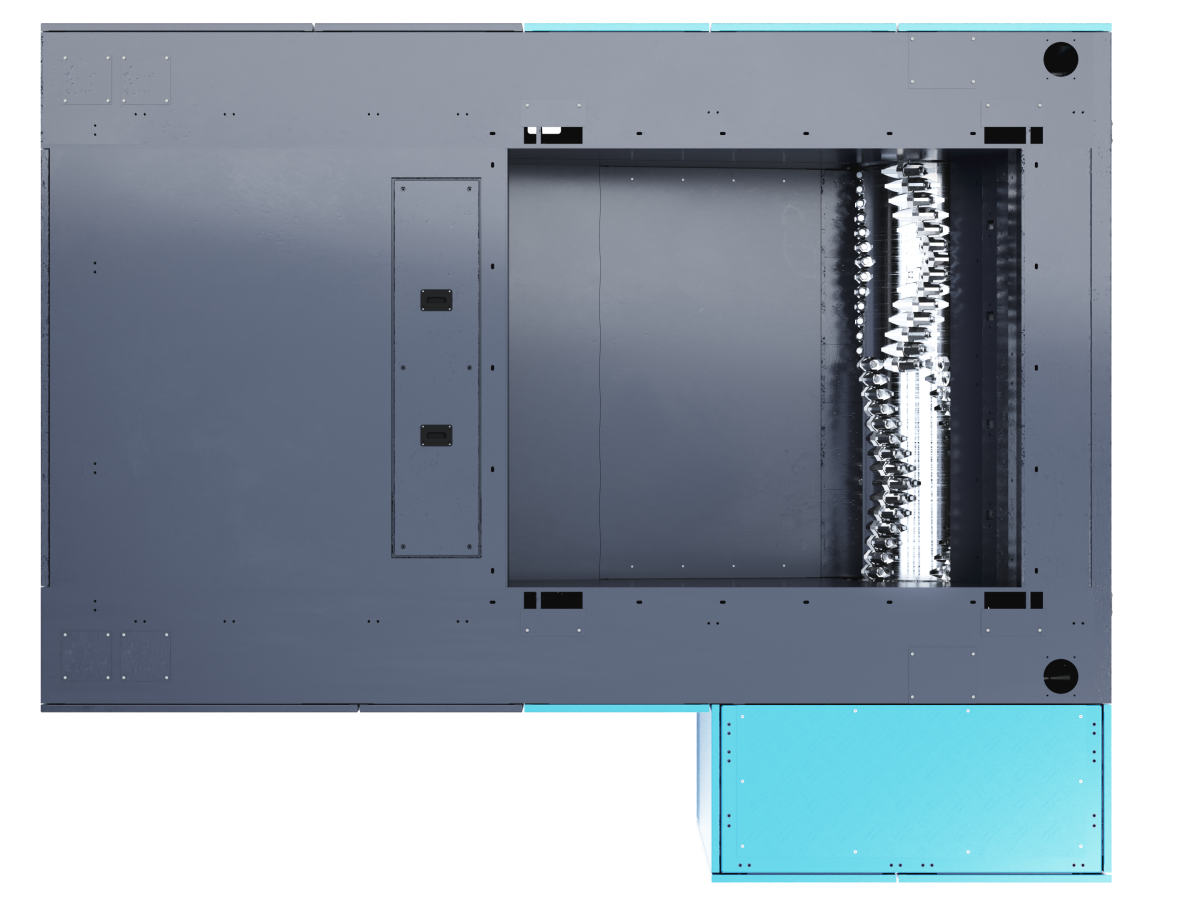

Adaptable to your requirements. The great advantage of our VAZ series is the wide range of configuration options with which we can adapt the shredder to your very individual requirements: Rotor lengths from 800 to 2500 mm, throughputs from 200 to 25,000 kg and various pneumatic, hydraulic or screw-on screen designs offer many customisation options. In addition, our three proven drive systems - the HiTorc direct drive, the ESC belt drive and the mechanical gearbox - allow further adaption.

Online product presentation

Webinar on the introduction of the new VAZ

The highlights of the large variants in the VAZ recyclables shredder series

The variants VAZ 1700, 1800, 2000, 2500 offer a lot more

Reibungslos im Handling:

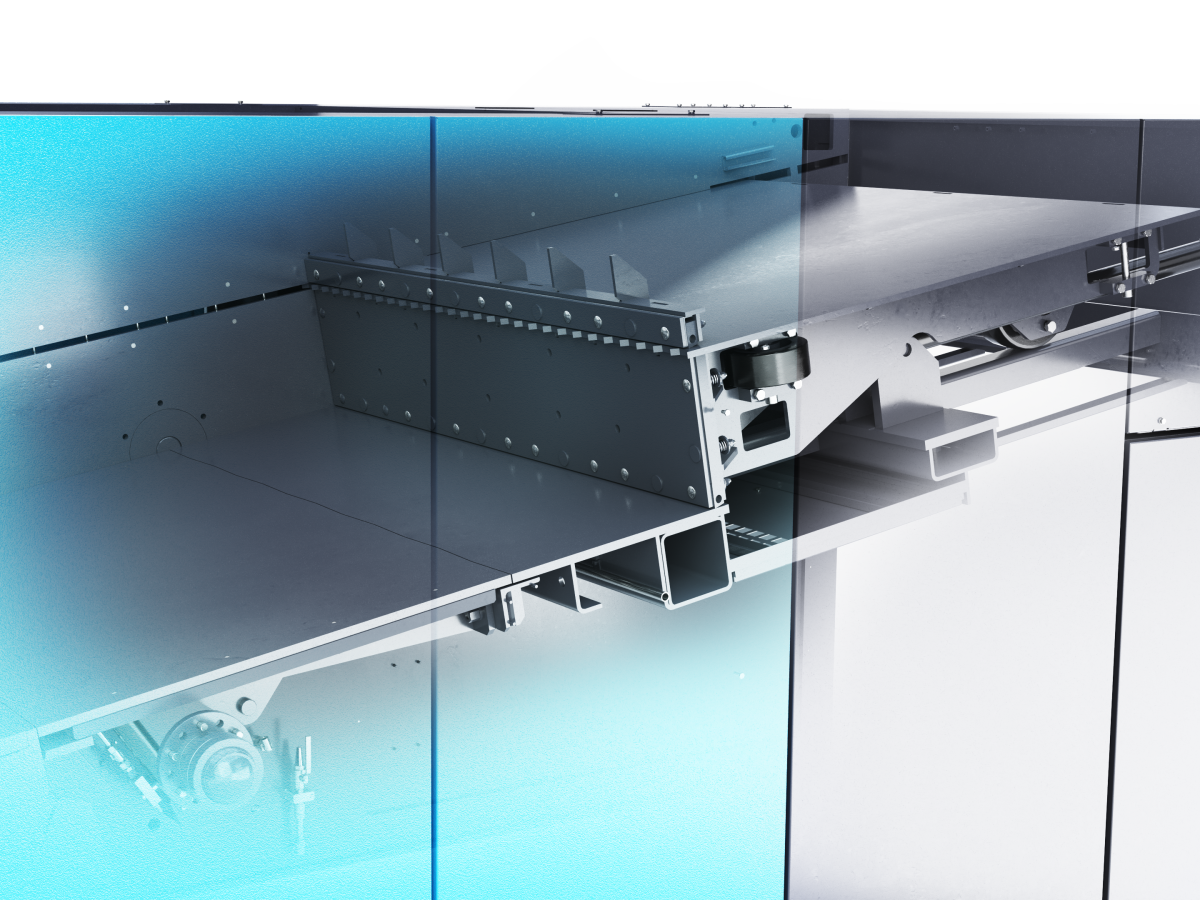

Hydraulische Bodenklappe

Automatische Störstofferkennung ermöglicht die konsequente Vermeidung von Maschinenschäden. Praktische, schnelle Störstoffentnahme erfolgt über die hydraulische Bodenklappe. Hierdurch werden konsequent Stillstandzeiten minimiert.

Your advantages at a glance

- Highest reliability and availability

- Energy savings of up to 50 %

- Optimum ease of maintenance

- Maximum homogeneous output with lowest fine dust content

- Best possible value creation thanks to consistent, high-quality output

- Counter knives adjustable from outside the machine

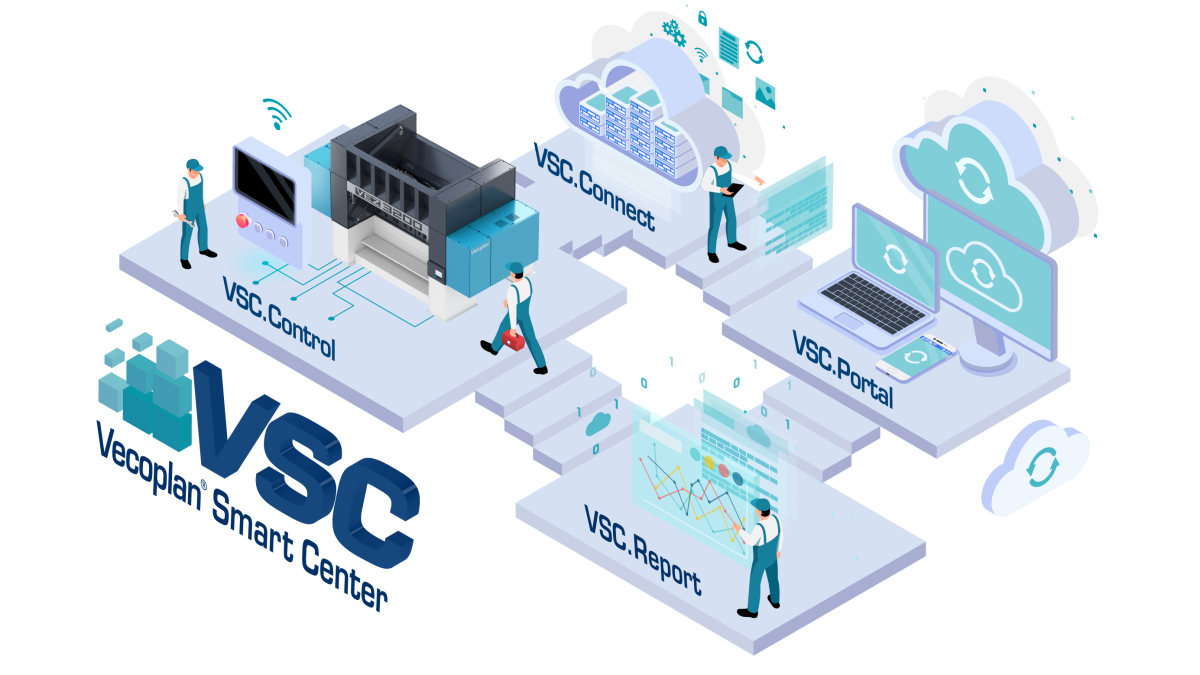

- Supported by the Vecoplan Live Service

Which model suits your needs?

| Specification |

|

|

|

|---|---|---|---|

| Type of drive | Direct drive HiTorc | Direct drive HiTorc | Direct drive HiTorc |

| Motor power | 111 - 247 kW | 111 - 247 kW | 111-246 kW |

| Speed range | 60 - 420 1/min | 60 - 420 1/min | 60 - 340 1/min |

| Rotor length | 1,660 mm | 1,937 mm | 2,490 mm |

| Rotor diameter | 640 mm | 640 mm | 640 mm |

| Weight | 20 to | 21,5 to | 19.5 to |

| Dimension (Length) | 4.750 mm | 4,750 mm | 4,620 mm |

| Dimension (Width) | 3.810 mm | 4,087 mm | 4,090 mm |

| Dimension (Height) | 2.340 mm | 2,340 mm | 2,375 mm |