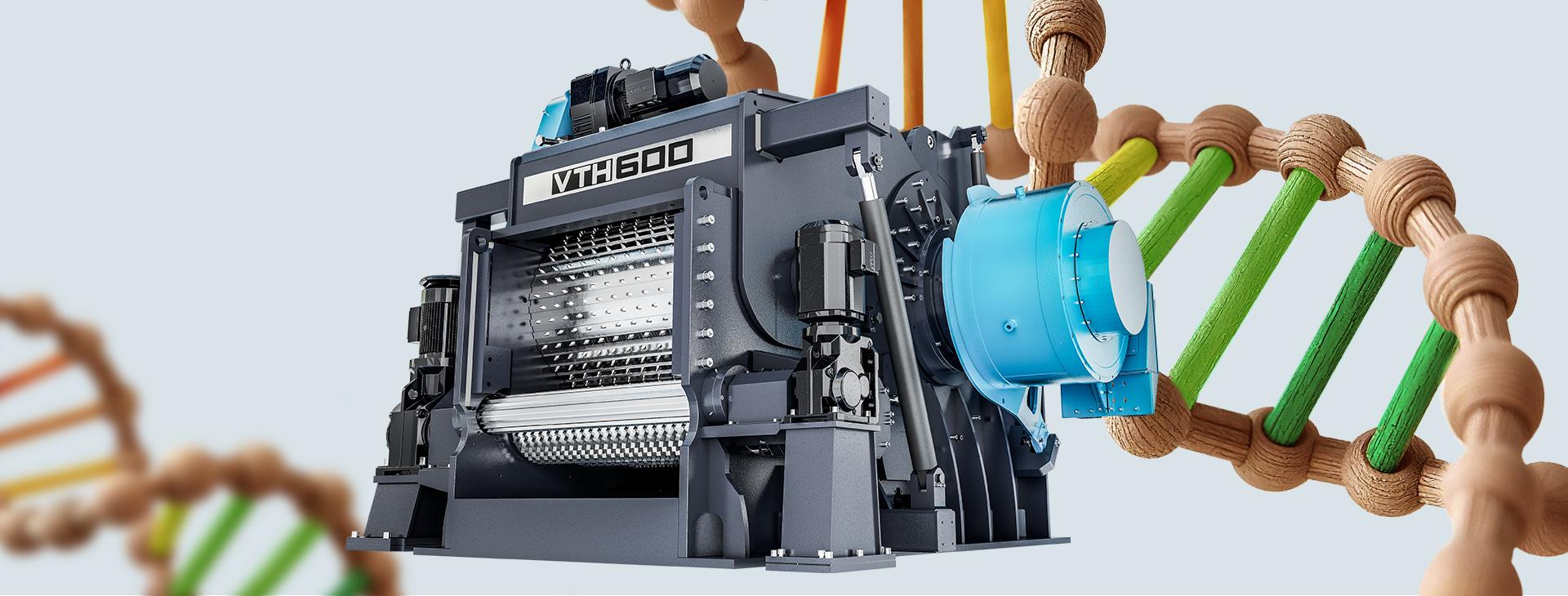

“In sawmills and biomass heat & power plants, our systems often run around the clock,” says Dirk Müller, Wood I Biomass Vice President at Vecoplan. “So downtimes cost plant operators a lot of money. This is why our customers need robust, low-maintenance and high-performance solutions – and that’s exactly what our new VTH 600-1050 BT biomass chipper is.” For decades now, the biomass chippers from the Westerwald-based mechanical engineering company have been making a name for themselves as real powerhouses. The compact Vecoplan biomass chippers achieve high material throughput rates. The quality of the wood chips is tailored to the individual application and can be easily adapted to meet the operator’s requirements. The technical innovation of this new chipper lies at its heart: the HiTorc drive! With the introduction of HiTorc into its biomass chipper series, Vecoplan is now transferring the single- and twin-shaft shredder technology that has proven itself over many years to the high-speed segment for the wood industry.

40 percent less energy, but 100 percent performance

This drive concept offers users many advantages: unlike conventional drive systems, the HiTorc doesn’t use any mechanical transmission elements like belts, couplings and gears – instead, the motor transmits the torque directly to the rotor shaft – so it’s highly efficient, blazingly fast and extremely precise. “We’re talking about up to 40 percent less energy consumption compared to conventional electro-mechanical systems. No other chipper has ever done anything like this before,” says Daniel Kessler, Vice President of Technology at Vecoplan. The HiTorc drive reacts as speedily as an electric car: “Dynamic start-up from a standstill and ready for use in three seconds – and this with peak torques and greatly reduced start-up currents. No other drive in this class can achieve this.” One of the functions carried out by the control system integrated in the frequency converter ensures that the best possible torque is applied to the rotor shaft at all times and in all its operating states making the HiTorc drive extremely energy-efficient. Thanks to the elimination of the mechanical drive elements, the HiTorc is around 10 to 15% more efficient than that of drive solutions with belt drives and even primary reduction gears. This gives the synchronous motor a hugely impressive degree of efficiency, especially in the partial load range. When idling, the motor only needs around 10% of the energy required by a comparable, directly switched asynchronous motor. The powerful HiTorc drive can process even difficult materials with the greatest of ease. However, the VTH 600-1050 BT retains the usual flexibility of Vecoplan machines and enables plant operators to adapt rapidly to different operating conditions and material requirements. Whether its pulsating power is used in the chipboard, sawmill or energy and pellet industries, or in biomass heat & power plants, this Vecoplan chipper can be flexibly integrated into many different applications – ranging from the production of fuel to the further processing of waste wood. Thanks to its compact design, the machine is also extremely space-saving, which significantly reduces installation costs as the operator won’t have to carry out any foundation work for motor systems with belt drives.

More than just mechanics: VSC users will enjoy a smart biomass chipper

The “Vecoplan Smart Center” digital operating concept (VSC) adds an intelligent service level to the physical mechanical technology. The intuitive control panel allows users to monitor operations efficiently and directly access online support or key performance indicators if required. The VSC essentially consists of two components: 1). The VSC.control – an intuitive control panel that serves as an interface between the operator and the machine. 2). The VSC.connect online platform, which provides access to digital services, including remote access, online commissioning, key performance indicators (KPI) monitoring and a media database. The VSC can reduce the operating costs of a chipper, explains Dirk Müller: “Remote monitoring can reduce costs through trouble-free operation, since operators can react fast to possible faults. On-site technicians are only seldomly needed, so travel times are saved. Operators can plan maintenance work to match the demand for their products, thereby also reducing downtimes.” Yet another advantage of implementing the VSC in the biomass chipper is the early detection of extraneous materials. Using vibration monitoring, the VSC can detect anomalies that indicate the presence of these materials and suggest suitable measures to rectify the situation.

Less maintenance, more power

The integration of the new drive concept also proves its worth if a rare malfunction should occur. The elimination of classic wear parts such as clutches, belt drives and flywheels significantly reduces maintenance costs and increases system availability. Plant operators who opt for the purely electrical HiTorc solution can wave goodbye to downtimes caused by burnt-out belts and faulty gearboxes. The VSC detects overloads at an early stage thanks to continuous evaluations of motor speed and electrical current. If any extraneous materials get into the machine, the rotor stops within a very short time. Even when the material charging system is completely full, the VTH 600-1050 BT will restart immediately. Thanks to the omitted mechanical components, the momentum of the solid rotor and the torque of the motor work together optimally, ensuring a smooth startup. The machine will start at any time at the touch of a button.

More innovation and efficiency with the HiTorc chipper

What does this new Vecoplan innovation mean for the industry? For Dirk Müller, the answer is clear: “The combination of energy efficiency and digital integration is changing the rules of the game. Our customers will increase their throughput, reduce their operating costs and improve their environmental footprint at the same time”. In times of rising energy prices and with an ever increasing number of legal requirements for sustainability, Vecoplan, with its technological leadership, has now provided a solution for the wood processing industry – the VTH 600-1050 BT with HiTorc drive. Technically sophisticated, economically convincing and digitally networked – a powerful innovation in shredding technology.