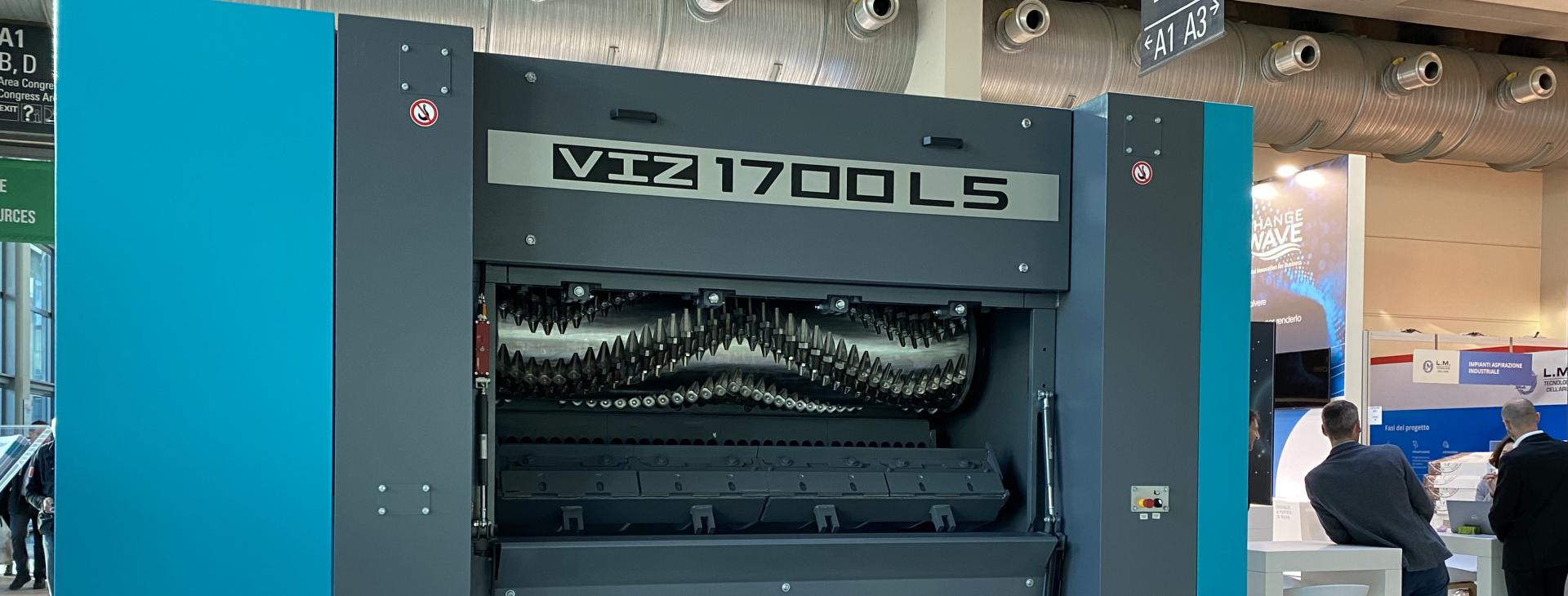

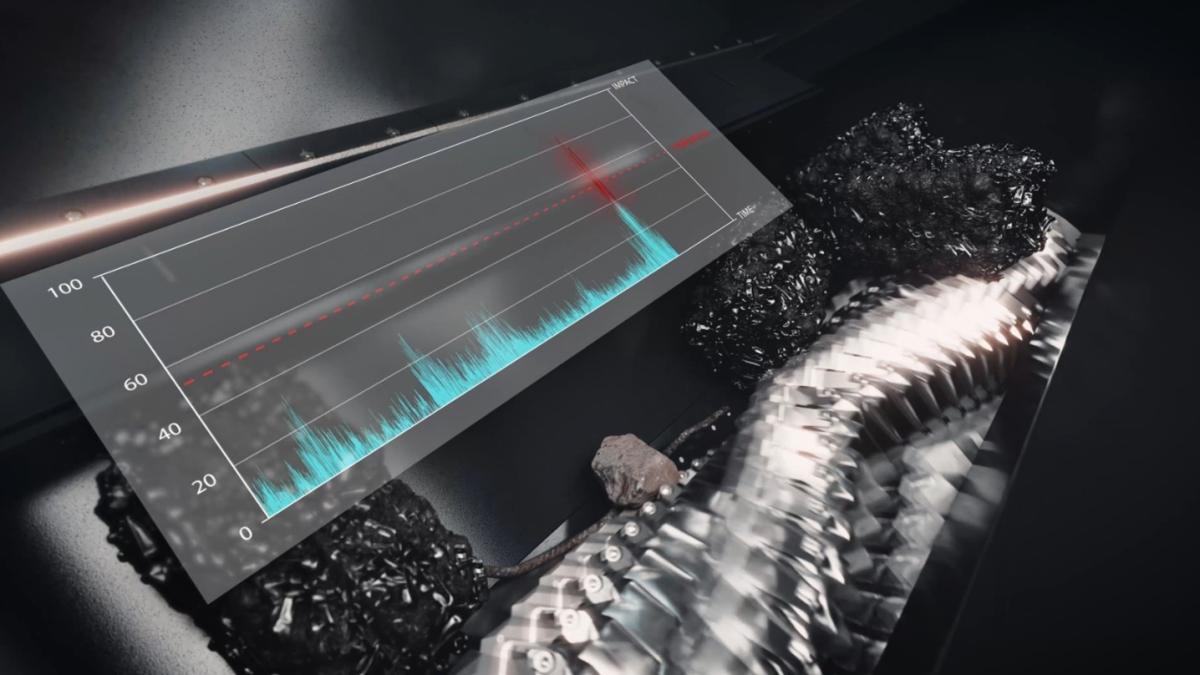

The Vecoplan VIZ 1700 shredder is designed for processing a wide variety of materials and can be flexibly adapted to specific requirements. “The system can be configured individually. Customers can choose between different drive types, rotor geometries and cutting crowns to get exactly the output they need,” explains Fabio Venturoli, Area Sales Manager at Vecoplan. In addition to its use in plastics processing, the machine has also proven itself in other applications, such as data and document destruction. One of the technical highlights is the Vecoplan HiTorc drive, which offers high performance combined with low energy consumption. The VIZ 1700 can also be optionally equipped with an automatic counter knife. This automatically adjusts the cutting gap, ensuring consistent grain sizes – without manual readjustment. An integrated foreign object detection system also helps to reduce downtime. The latest generation of this electronic system triggers an immediate machine stop in the event of foreign objects. This drastically reduces downtime and potential damage compared to conventional systems. Also available as an option is the Vecoplan Smart Centre (VSC), which records all operating data and offers additional support via a remote service function.

The complete process chain from a single source

With these technological advances, Vecoplan AG is consolidating its position as the technology leader in the industry. In addition, the company recently announced the integration of washing technology specialist Pla.to from Görlitz. Vecoplan now offers the entire recycling process chain from a single source – from shredding and conveyor technology to state-of-the-art cleaning technology for plastics. Dry cleaning in particular is considered a key technology. The dry cleaner removes contaminants such as paper fibres, dust or organic residues mechanically and completely without water. It is therefore considered particularly resource-efficient. “We see ourselves not only as a machine manufacturer, but also as a partner to our customers. In addition to our high-performance systems, from shredding to dry cleaning, we attach great importance to fast service and competent support from our specialists,” Venturoli continues.

Interested visitors can find the Vecoplan team at Ecomondo in Hall A2 | Stand 201-100.