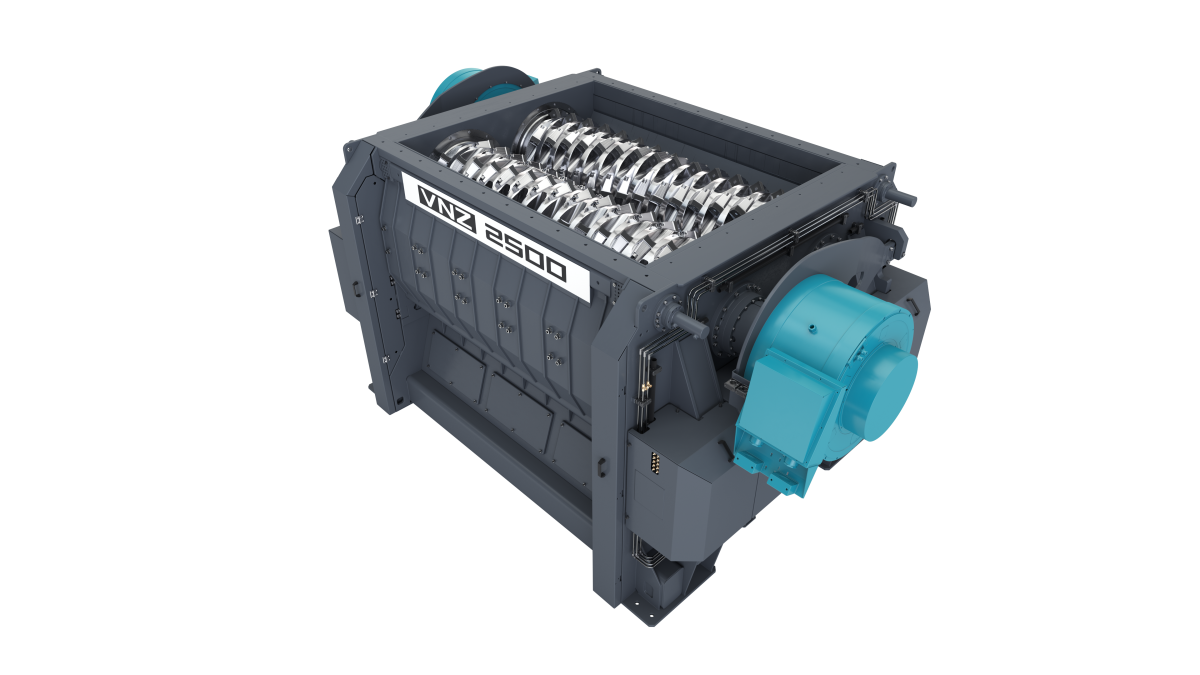

VNZ - Re-shredder

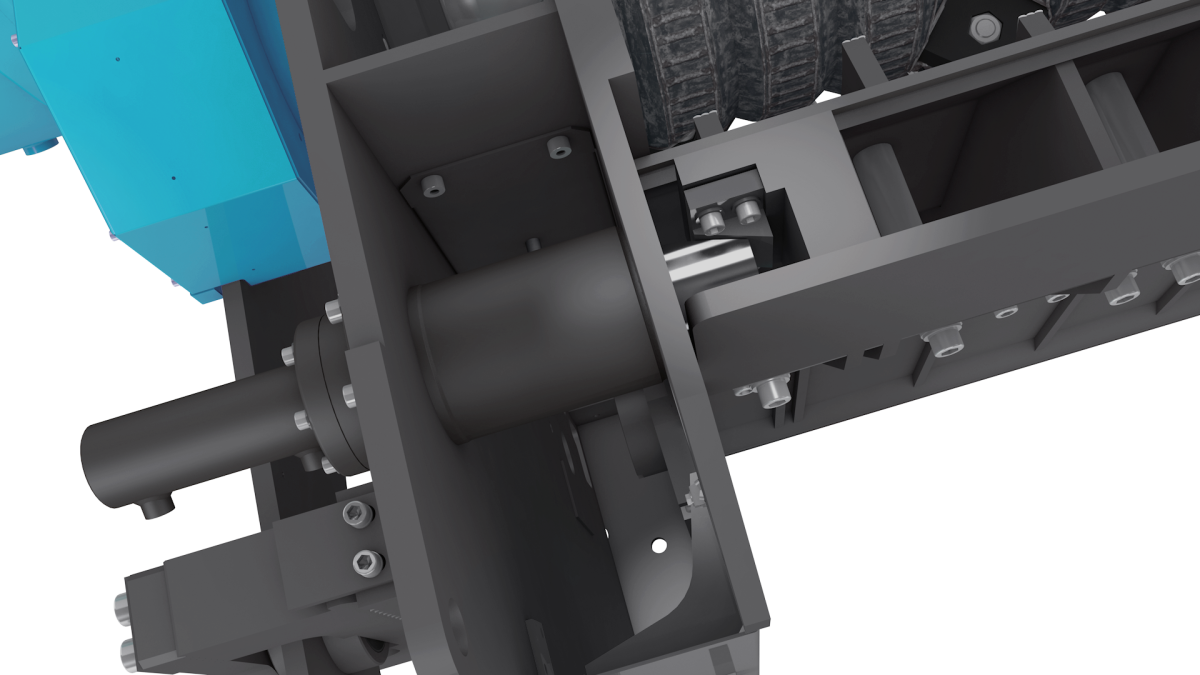

Powerful re-shredding of pre-crushed materialWith our VNZ series, you get high-performance secondary shredders in a robust design, which have been specially developed for the re-shredding of pre-crushed material to produce separable material for value and material use. Waste wood, pre-shredded domestic, industrial and commercial waste, production waste, straw, root wood and much more can be processed without any problems. Various rotor systems and geometries are available for optimum shredding performance with different material tasks.

VNZ - Re-shredder

The strongest among the double-shaft re-shredders

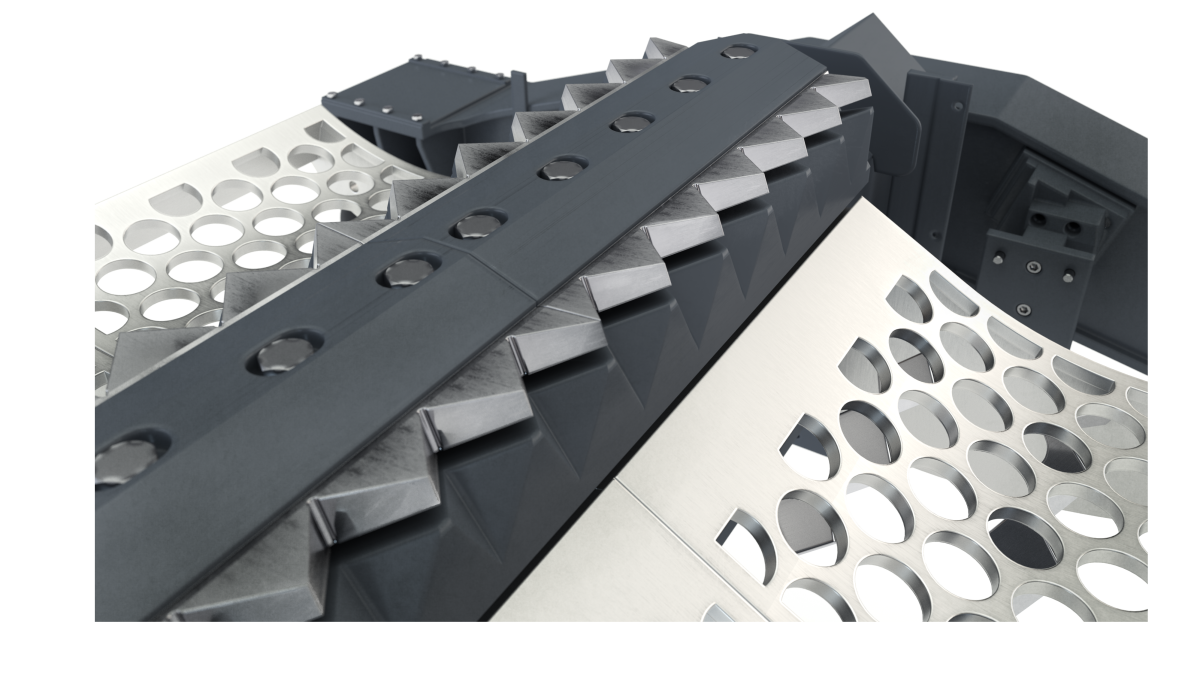

The Vecoplan double-shaft shredder was developed for the re-shredding of pre-crushed waste wood, pre-shredded domestic,industrial and commercial waste, production waste, straw, root woodand much more. We can deal with a great variety of input materialsand match customer requirements, thanks to our different cuttingtools, counter-knife variants and matching perforated screens.

The highlights of the VNZ - Re-shredder

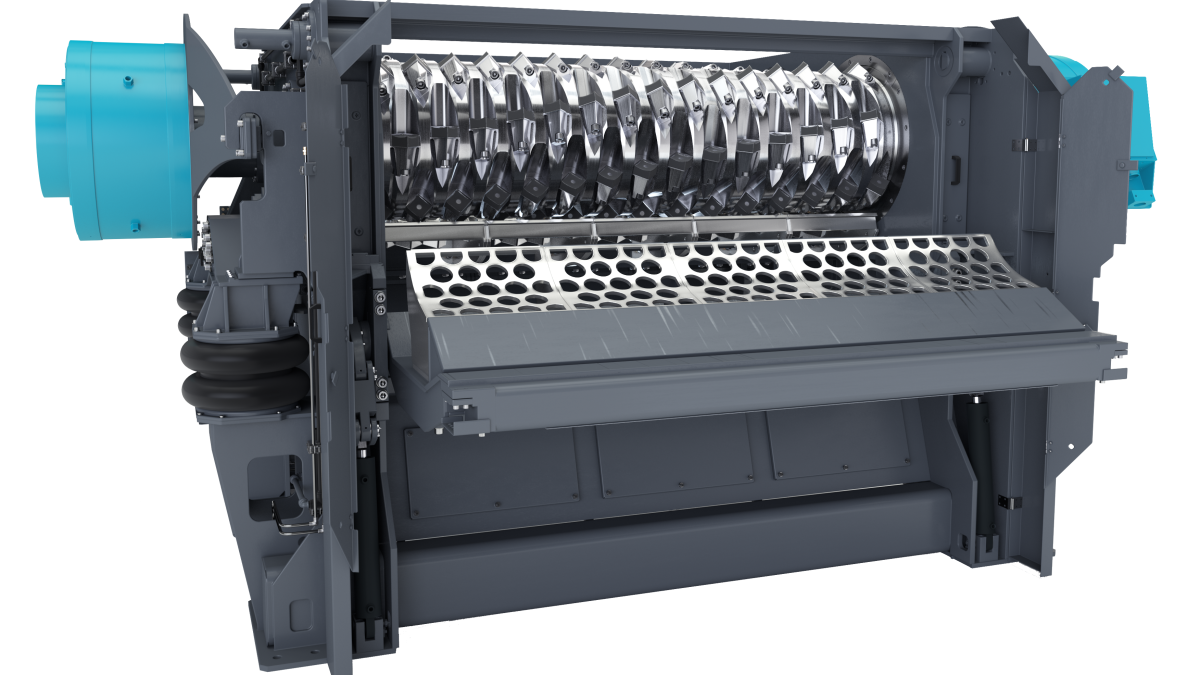

Indestructible power thanks to a robust construction

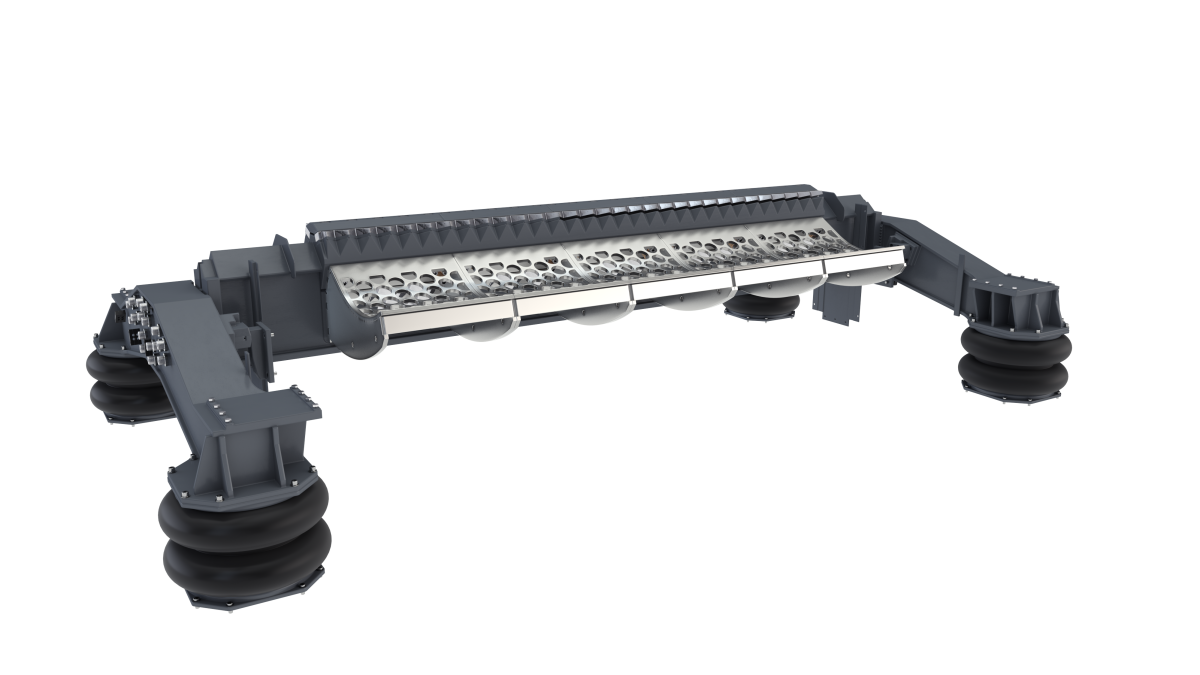

The basis for efficient and trouble-free operation is the machine housing, consisting of a thick-walled, ribbed construction with optimum functional machine geometry.

The two solid steel rotors with their large flywheel masses ensure smooth machine operation and high throughput. The interaction of the two rotors with the common counter knife and the perforated screens results in a very separable and homogeneous output. Hydraulic maintenance doors facilitate the replacement of wear parts and the removal of impurities, even when the filling hopper is completely full.

Your advantages at a glance

- Highest reliability and availability

- Cost minimisation through energy efficiency

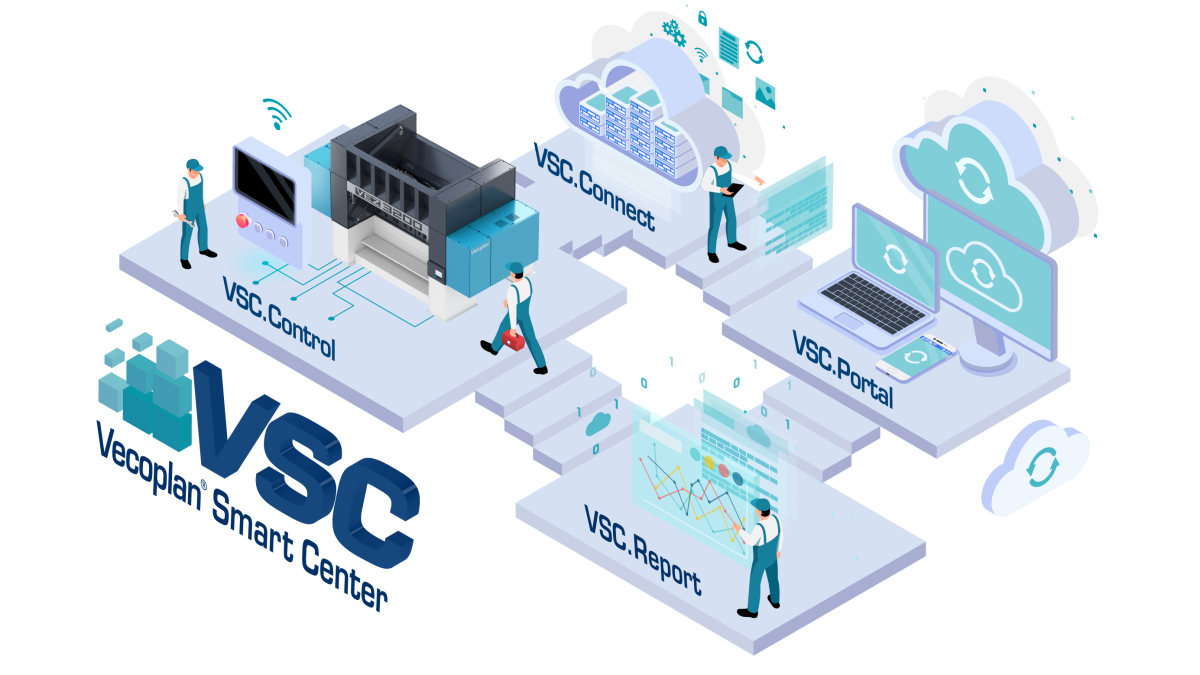

- Optimisation of maintenance and service

- Best added value through consistently high, high-quality output

- Support through Vecoplan Live Service

Which model suits your needs?

| Specification |

|

|

|

|---|---|---|---|

| Type of drive | Electromechanical drives | Direct drive HiTorc | Electromechanical drives |

| Motor power | 75 - 110 kW | 134 kW | 90 - 110 kW |

| Speed range | 165 - 165 1/min | 60 - 230 1/min | 165 - 165 1/min |

| Rotor length | 2,100 mm | 2,500 mm | 3,000 mm |

| Rotor diameter | 500 mm | 640 mm | 500 mm |

| Weight | 12.8 to | 24.5 to | 15.5 to |

| Dimension (Length) | 4,010 mm | 5,120 mm | 4,380 mm |

| Dimension (Width) | 2,400 mm | 2,580 mm | 2,750 mm |

| Dimension (Height) | 1,850 mm | 1,975 mm | 2,100 mm |