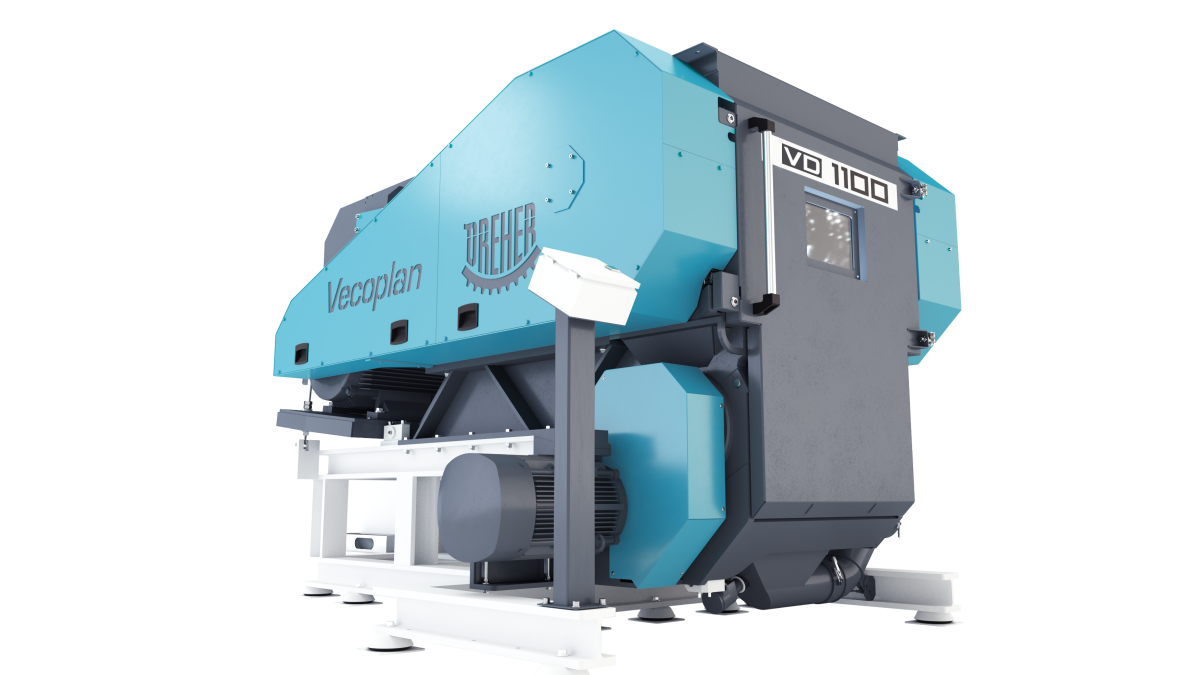

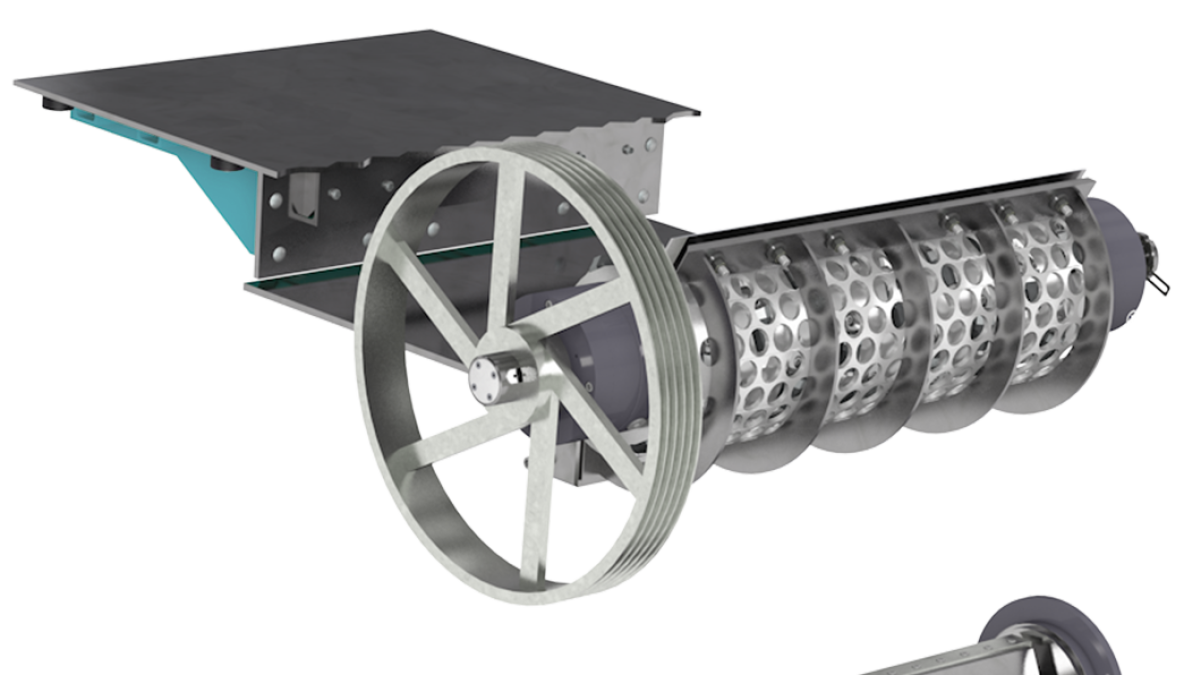

Combined shredder granulator (VDZ)

2 in 1 – Shredder Granulator Combination for two stage shreddingThe intelligent inhouse solution of the VDZ is a design jointly developed based cutting mill specialist Heinrich Dreher GmbH & Co. KG from Aachen and Vecoplan AG. This combines the expertise in cutting and shredding of two German plant and machine manufacturers in one machine housing. The machine crushes the input material from a lump in two stages to granulat in the desired output grain size for direct reuse in the production flow.

Save space and resources with the shredder granulator combination

Compact and united – The well-proven combination of shredder and granulator for the two-stage shredding of production waste in the plastics industry

For plastics recyclers and processors, this means an enormous increase in efficiency: only one process step and only one machine is required for efficient plastics processing.

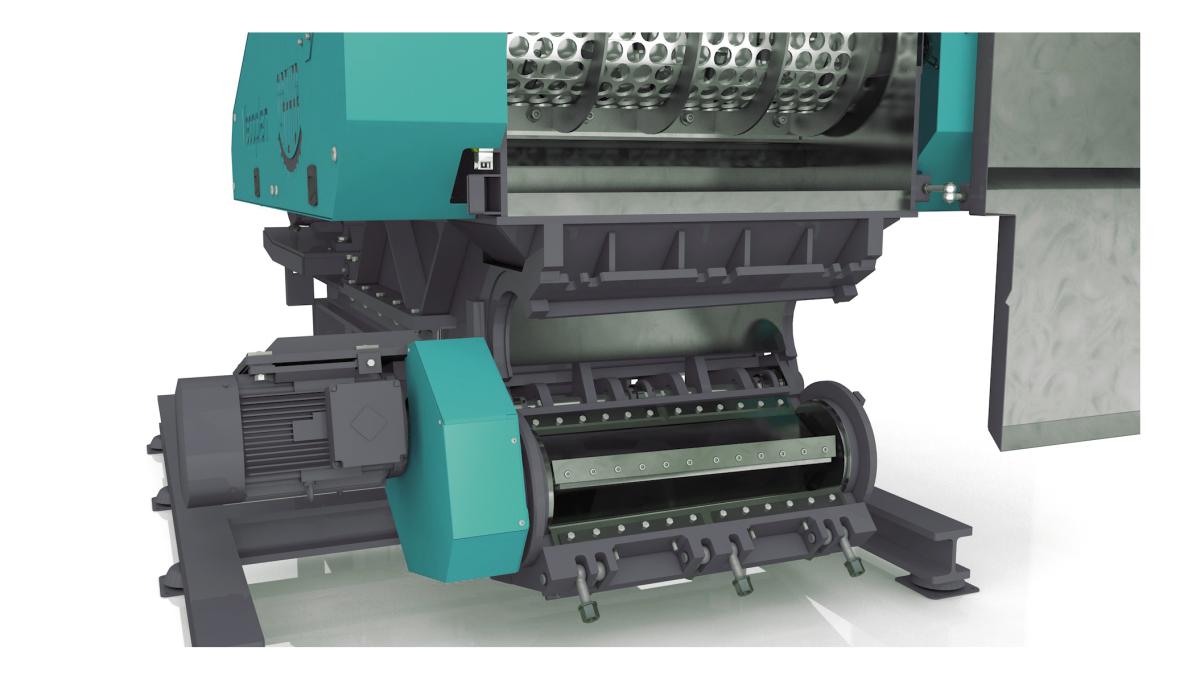

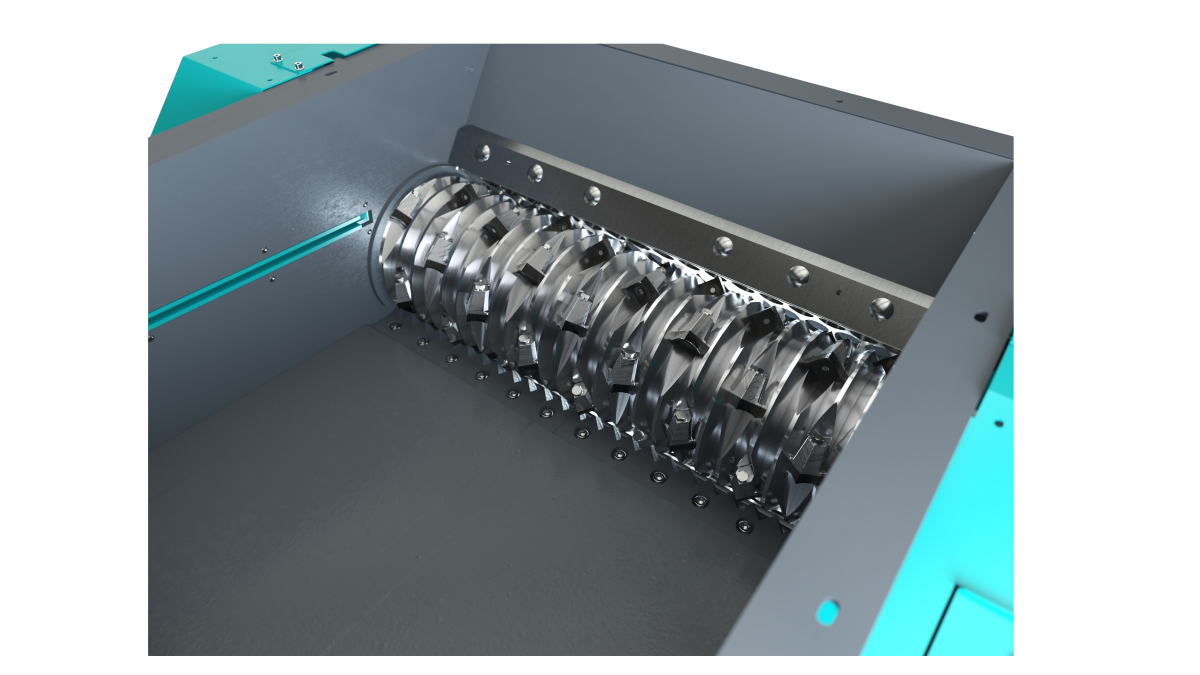

The new VDZ shredder-grinder combination has been specially designed for shredding input material such as start-up lumps, chunks, bulky items and cork, as well as large-volume components such as IBCs, canisters and drums. With this two-stage shredding solution, you can achieve a throughput rate of up to 1,500 kg/h.

The higlights of the new VDZ - Combined shredder granulator

From bulk to granulate with a single machine

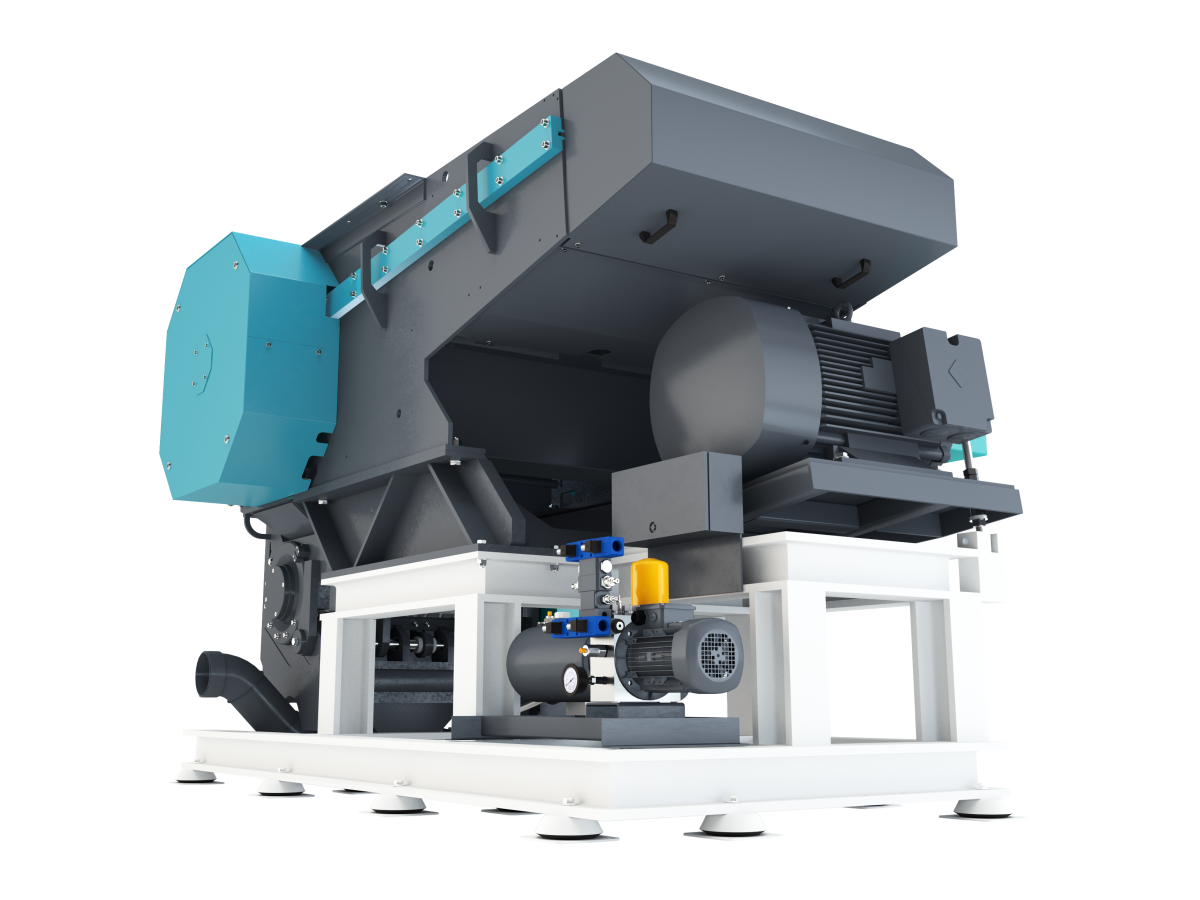

The VDZ combines cutting and shredding in just one machine. The direct combination of granulator and shredder eliminates the need for conveyor technology and also means lower connection and consumption costs.

The machine housing is a thick-walled, ribbed steel construction. The machine base is an integral part of the machine. This reduces noise emissions and enables further simplified noise protection measures.

Your advantages at a glance

- 70 % space saving

- 25 % energy savings through ESC-Drive compared to electromechanical direct drive

- Highest reliability and availability

- Safety performance level D2

- Lower connection and consumption costs

Gain an impression of the technical details

The VDZ from Vecoplan has been specially developed for shredding large-volume input material and implements the two steps (pre-shredding and grinding) in one machine:

Does this model suit your needs?

| Specification |

|

|---|---|

| Type of drive | Belt drive ESC |

| Motor power | 30 - 37 kW |

| Speed range | 95 - 265 1/min |

| Rotor length | 1,070 mm |

| Rotor diameter | 370 mm |

| Weight | 6 to |

| Dimension (Length) | 3,360 mm |

| Dimension (Width) | 2,164 mm |

| Dimension (Height) | 1,968 mm |