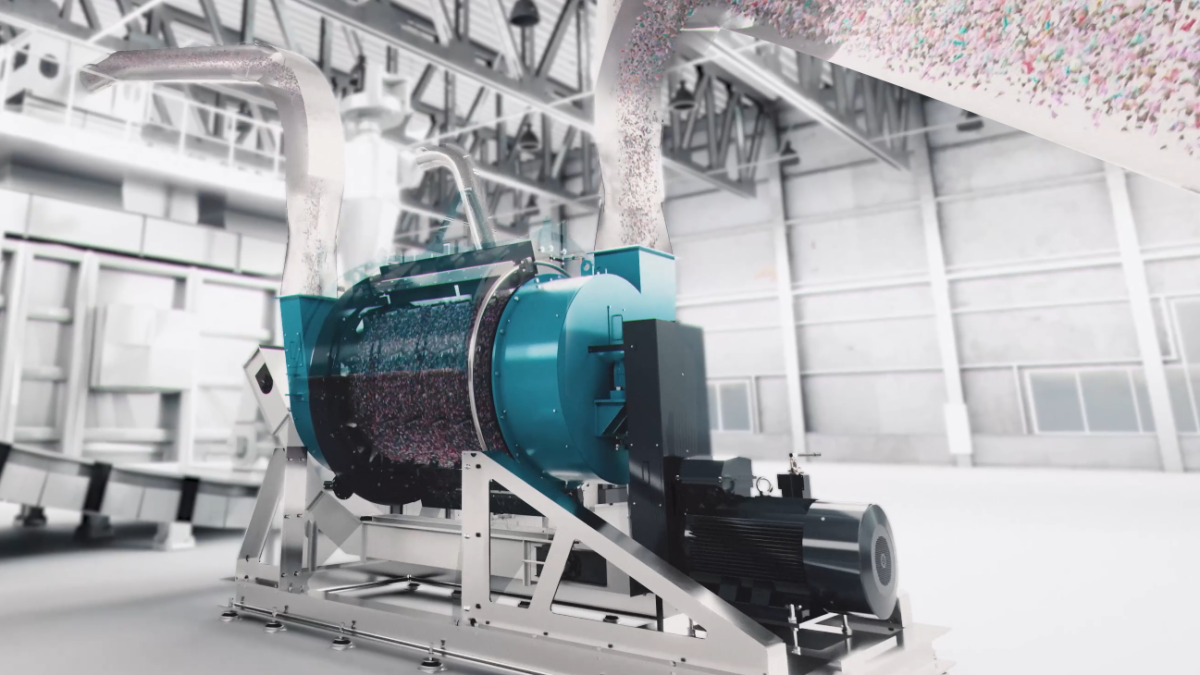

Heavy Duty Shredder

Exceptionally reliable – the Heavy Duty Plastic ShredderOur VHD plastic shredder is strong in starting and high-torque which are the ideal prerequisites for shredding solid plastics with the highest mechanical properties.

Almost regardless of geometry and weight, powerfully and reliably on a permanent basis.

Use the advantages of the Heavy Duty Plastic Shredder

Enduring and strong - the powerhouse for shredding massive input materials

The Vecoplan Heavy Duty is a more robust and powerful plastic shredder that can be adapted to the size of the demanding input materials by choosing between two different rotor diameters. This ensures efficient, trouble-free operation with maximum service life for maximum availability. Depending on the input material and screen hole diameter, throughput rates of up to 8000 kg/h are possible. The VHD achieves durability through a thick-walled, multi-ribbed machine housing, reinforced side walls and a stable machine floor. Unique in this application is our HiTorc drive. It works dynamically and is strong in starting and torque. The drive does not require any mechanical elements such as gears, belts, clutches or hydraulic units.

The highlights of the new VHD - Heavy duty plastic shredder

Your advantages at a glance

- Millless shredding of solid materials almost regardless of size and weight

- Maintenance-free synchronous motor as direct drive without mechanical drive train.

- All machine components of particularly solid and stable design

Shredding of heavy, technical hard plastics - the VHD in practice

A supplier of thermoplastics recycles production waste in-house. In close cooperation with the customer, Vecoplan designs a single-shaft shredder in a particularly robust version that handles a direct and unsorted feed of the material almost regardless of size and mass.

Which model suits your needs?

| Specification |

|

|

|---|---|---|

| Type of drive | Direct drive HiTorc | Direct drive HiTorc |

| Motor power | 111 - 134 kW | 134 / 155 kW |

| Speed range | 60 - 230 1/min | 60-230 / 40-230 1/min |

| Rotor length | 1,600 mm | 1,600 mm |

| Rotor diameter | 495 mm | 640 mm |

| Weight | 14.6 to | 15.6 to |

| Dimension (Length) | 4,600 mm | 4,600 mm |

| Dimension (Width) | 3,130 mm | 3,130 mm |

| Dimension (Height) | 2,375 mm | 2,375 mm |