The production of goods and commodities generates harmful emissions that increase the natural greenhouse effect. This inevitably leads to temperature changes with far-reaching consequences for the climate. Greenhouse gas emissions must therefore be reduced by at least 55% throughout Europe by 2030, and Europe intends to be climate-neutral by 2050. “The circular economy is one of the tools that can be used to achieve these goals,” says Martina Schmidt, who heads the Recycling and Waste division of Vecoplan AG. Vecoplan is one of the leading suppliers of machinery and equipment for processing primary and secondary raw materials for thermal and material recycling. “In the field of product design and packaging, using recycled plastics offers many possibilities for substitution,” says the Vecoplan expert. “According to the UMSICHT study by the Fraunhofer Institute, climate-damaging greenhouse gas emissions can be reduced by up to 50% if recyclate is used instead of new granulate from crude oil. We have to leverage this potential.”

However, recycling is not only crucial for climate neutrality, it also conserves valuable resources and the environment. A wide range of industries in the plastics industry are undergoing a transition. The aim is to increase the recycling rate and use the advantages of plastic in such a way that no damage is caused to the environment. The increasing demand in the various industries is leading to a tense supply situation and acting as a price driver. “We’re seeing a clear trend towards increased demand for high-quality plastic recyclates. Many manufacturers are closing their cycles because that enables them to influence this demand and deal with it,” explains Martina Schmidt.

Taking recycling into their own hands

Processors can quickly and cost-effectively satisfy the demand for high-quality recyclates by taking reprocessing into their own hands and following a holistic approach. “We work closely with our customers in developing our solutions,” says Schmidt. “In the past, processors always came to us with new challenges, which motivated us then – and still does today – to actively shape this change.”

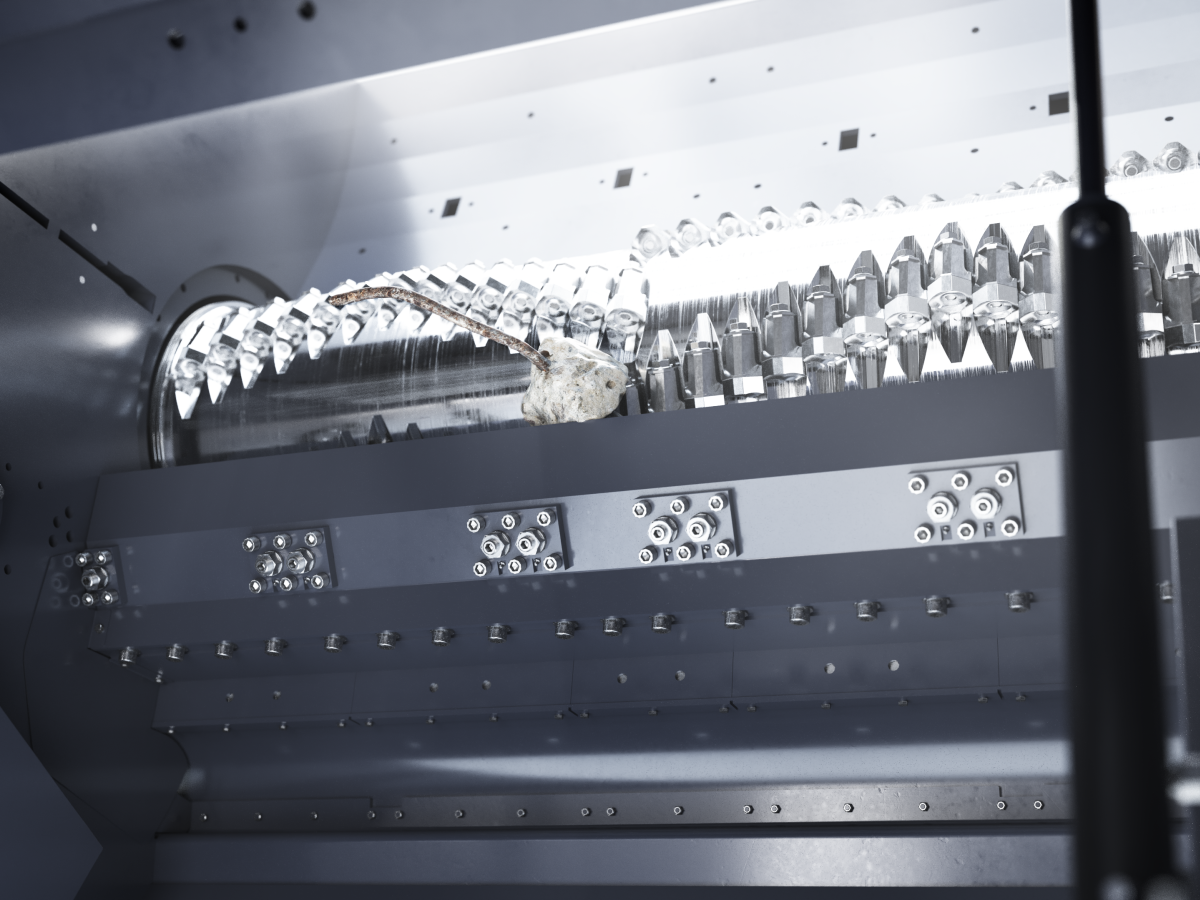

The shredding of the materials is particularly challenging. For example, yarns, fibres and filaments are available in different thicknesses, in various and often extreme lengths and are made from various plastics. However, despite all their differences, they also share some unique mechanical properties – they are tough, wear- and tear-resistant and very elastic – which makes shredding all the more difficult. “A homogeneous output material is optimal for all downstream processes,” explains Schmidt. “That’s why excessive lengths and fine particles should also be avoided because they can cause disruptions or losses during the process.” In addition, to ensure effective downstream processing of the plastics, the characteristics of the input material must not be changed by the heat input that arises during shredding.

Focused on energy efficiency

Vecoplan relies on its exceptional HiTorc drive to achieve the best possible energy efficiency during shredding. Thanks to eliminating mechanical drive elements such as belt and gear drives, flywheels and clutches, the direct drive is 10-15% more efficient. The HiTorc is dynamic, has a strong start-up phase, is low-maintenance and is insensitive to extraneous materials. Even one unscheduled plant stoppage caused by a broken shaft, burnt overload clutch or defective gear is enough to justify using a HiTorc drive since it significantly reduces maintenance work and downtimes. “Our HiTorc is the Tesla among today’s drives,” says Martina Schmidt.

Technology is key

Achieving the optimal coordination for the case at hand then continues with the selection of the ideal cutting unit, and here Vecoplan technicians work closely with their customers. “We develop shredders, which we individually coordinate through many tests in our technology centre. The test results are documented, made available to the customer and included in our database,” says Schmidt. The database now includes more than 3,000 tests. Output material temperature, noise emission, torques and cutting forces are monitored and recorded in real time. Vecoplan also has an in-house laboratory for measuring moisture, testing material and determining grain size & density. “In recent years, we’ve developed an enormous level of theoretical and above all practical knowledge,” says Schmidt. Simple maintenance and the greatest possible ease of operation are essential aspects of all developments.

En route to the perfect system

Is there a perfect machine? Martina Schmidt thinks about that for a moment. “To answer this question, we first have to define what we mean by a perfect machine.” Is it a shredder that’s correctly configured for the usage scenario? And can it handle a few measures such as adjustments to the cutting force, a changed cutting geometry or output size? “Our shredders offer a high degree of flexibility to meet these requirements,” she says.

Or should a perfect machine ensure stable processes and produce consistently high throughput and a homogeneous output material at all times? “Our customers also trust us to provide them with these machine features too,” says the Vecoplan expert.

“However, let’s not forget that sustainability is playing an increasingly important role. For example, how the possibilities of digitalisation can be exploited to add value for the customer, such as in the context of new business models. That’s what we’re working on.”

A powerful solution

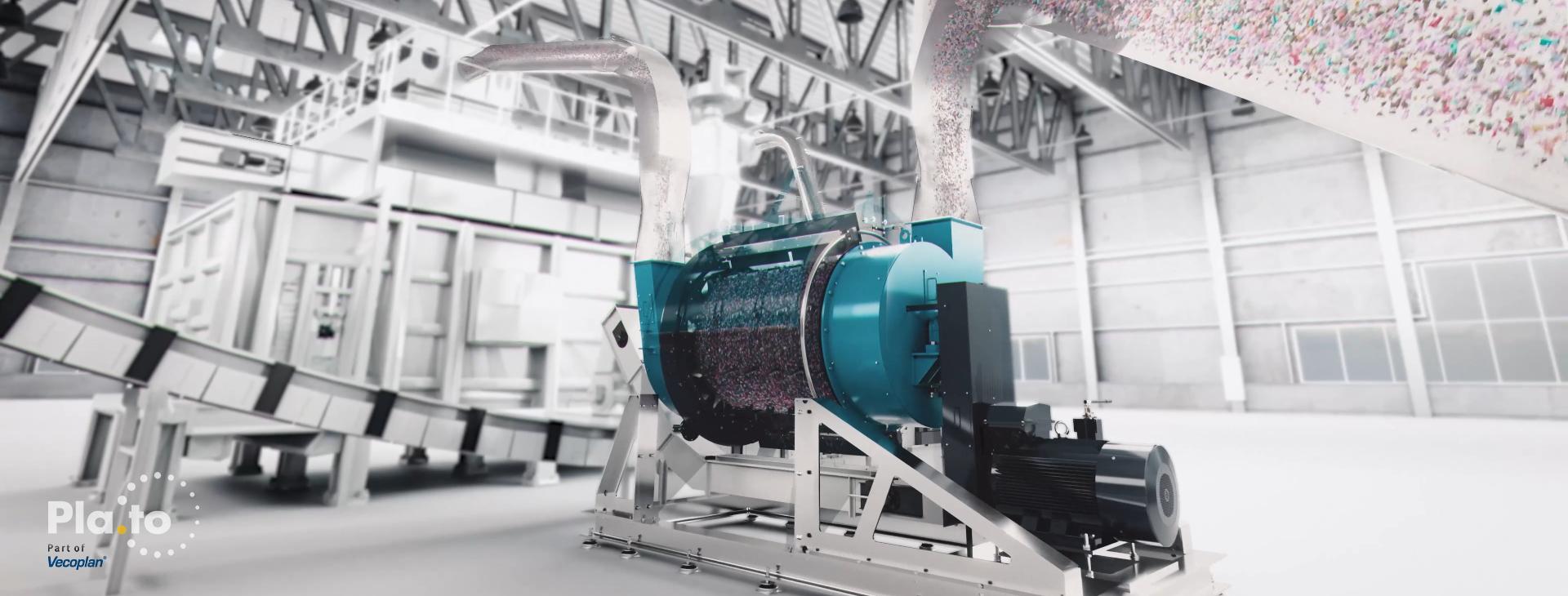

To meet the high demands for the recycling of very different materials, Vecoplan revamped its proven, successful VAZ shredder series with the latest benchmarks in industrial design – and presented the series for the first time at IFAT in May 2022. The modular design of this single-shaft shredder particularly convinces users. “It allows operators to use the series universally and get the right answer for a wide range of applications,” promises Schmidt. “We have many options for configuring and adapting the machine to the task at hand. These choices and the relevant combinations are critical to the performance and quality of the shredding process.”

The new shredder is also equipped with the Vecoplan Smart Center (VSC), Vecoplan’s powerful digitalisation concept for the maximum efficiency of shredders and systems. The integrated and intuitive VSC.control operating panel serves as a communication medium for the cutting-edge control of the machine and direct communication with Vecoplan. VSC.connect enables users to network their machines and access additional online services, such as remote service, key performance indicators and even a media database.

The HiTorc drive is distinguished by its high level of efficiency. Among its many other advantages, the drive enables the machine to be started up under full load.

The new VAZ combines attractive technical features with a functional and modern design.

Martina Schmidt, Head of the Recycling I Waste division at Vecoplan AG.

Photography credits: Vecoplan AG