VDB, VZB – Hydraulic discharge device (pushing cylinders)

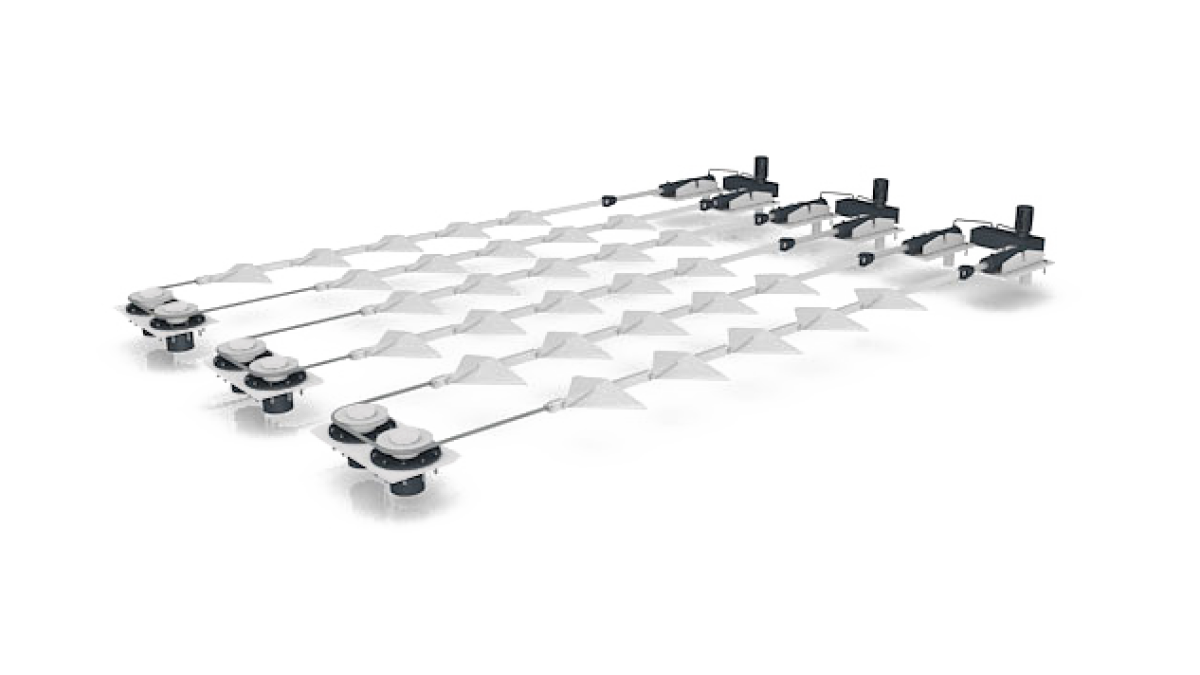

The Vecoplan traction pull rod dischargers are specially designed for high discharge capacitiesDo you need a pull rod discharger to discharge bulk material such as wood chips, sawdust, RDF, shredded film and plastics from your silo, deep bunker or storage boxes? Our VDB and VZB series are efficient systems with high performance. Each drive unit works independently with its own control system and optional energy-efficient frequency converter.

Advantages at a glance

- Available as standard version (VZB) or delta version (VDB)

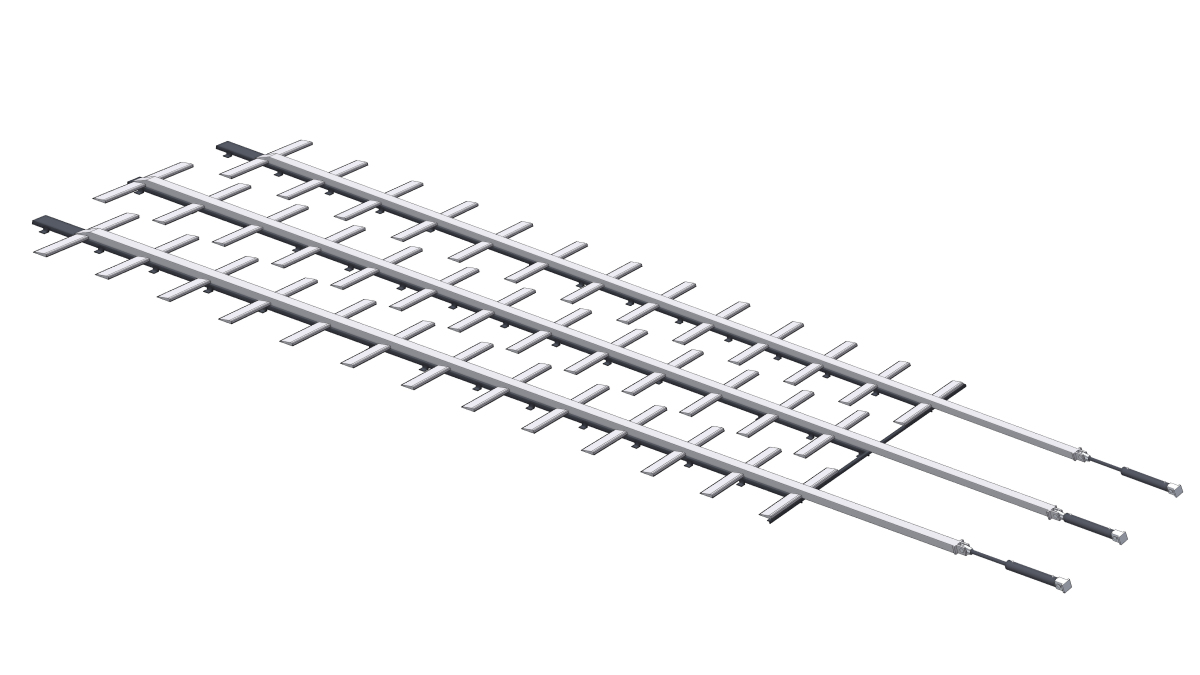

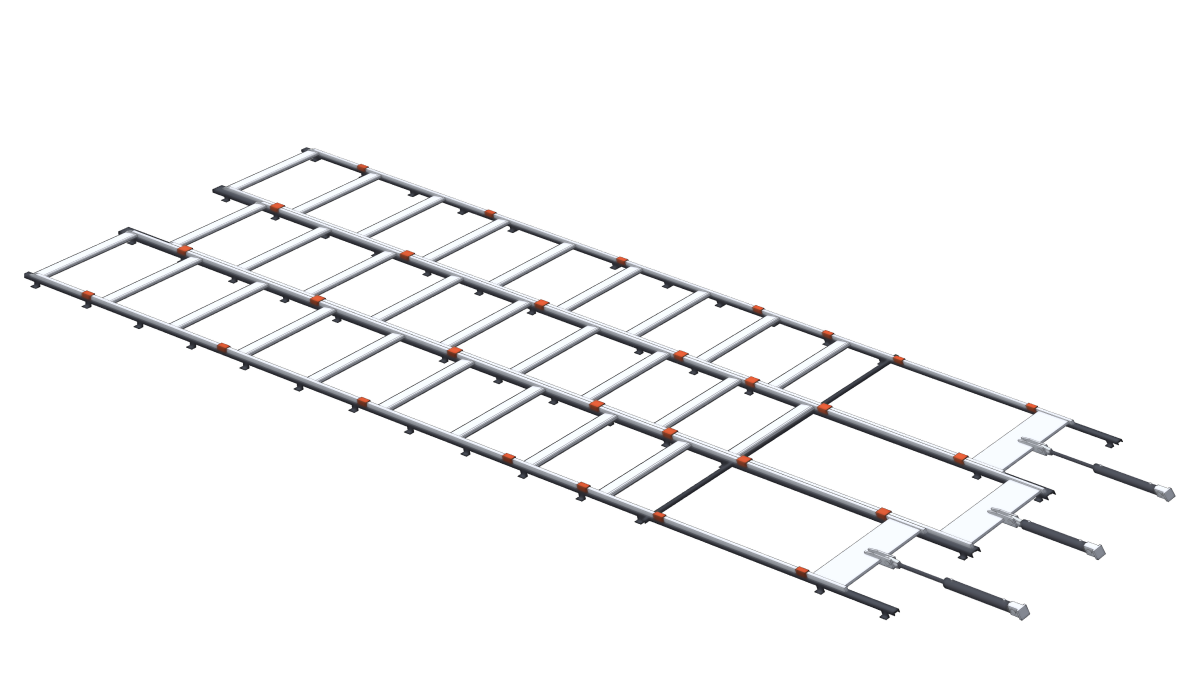

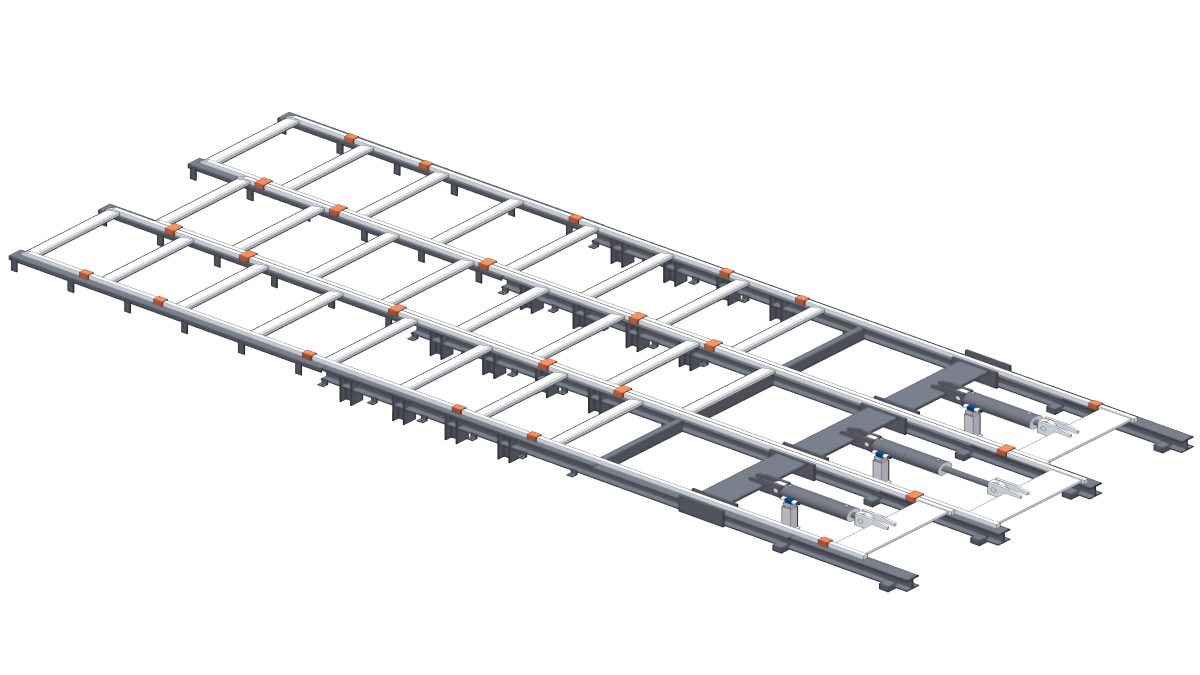

- Each conductor segment can be controlled independently

- Optionally with energy-efficient frequency converter for metered discharge capacity

- Available as "non-trafficable", "trafficable" and "force-reduced", for a particularly small load introduction into the foundations

Which model suits your needs?

| Specification |

|

|

|

|

|

|

|---|---|---|---|---|---|---|

| Weight | - | - | - | - | - | - |

| Dimension (Length) | max. 10,000 mm | max. 10,000 mm | max. 10,000 mm | 17,000 mm | 17,000 mm | 22,000 mm |

| Dimension (Width) | 1,500 mm | per segment 2,000 mm | per segment 2,500 mm | per segment max. 2,000 mm | per segment max. 2,000 mm | per segment max. 2,000 mm |

| Dimension (Height) | max. 7.000 mm | max. 7.000 mm | max. 7.000 mm | Fill level + 500 mm | Fill level + 500 mm | Fill level + 500 mm |

| Filling height | 6,000 mm | 6,000 mm | 6,000 mm | 8,000 mm | 8,000 mm | 8,000 mm |

Can be used for following material

Wood

Biomass

Plastics - post-consumer

Plastic - post-industrial

All