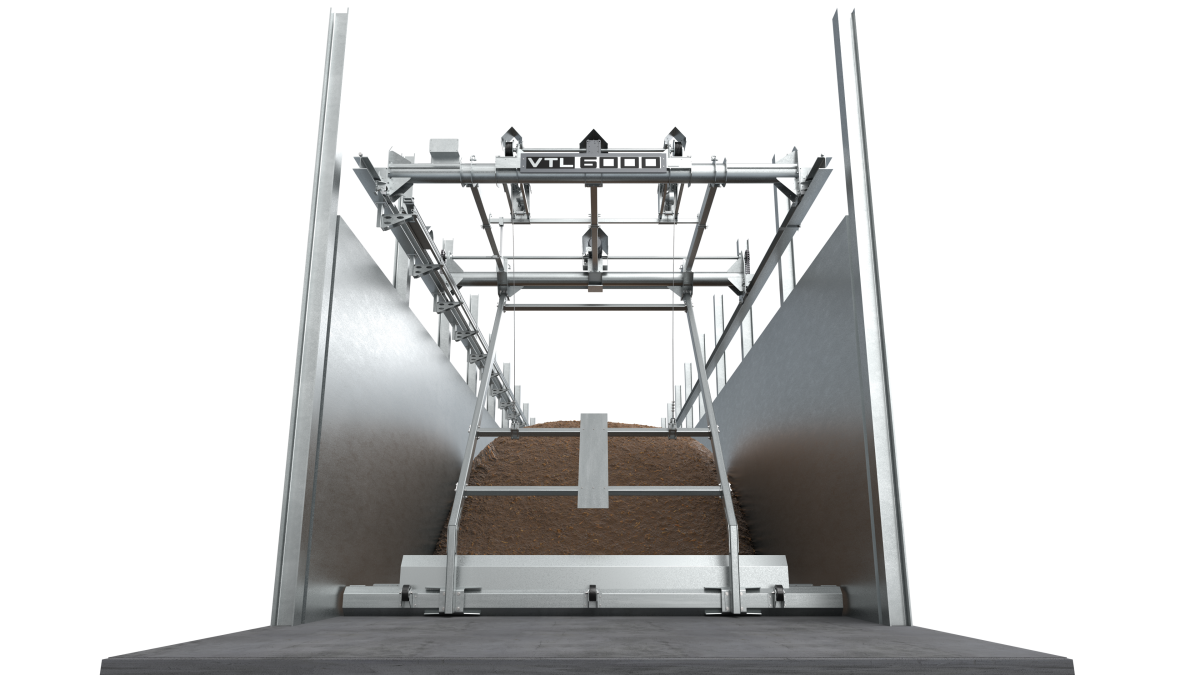

VTL Toploader – Efficient Bulk Material Storage & Feeding

The most economical storage technology for various bulk materials like wood chips, old timber, bark, RDF, corn, grass and plasticWith our VTL Toploader system, you can store bulk material fully automatically and discharge it in a metered manner. You can use our toploader, for example, to feed the boilers in biomass power plants, as a truck receiving station, as storage boxes for chips and shavings in pellet plants or for substrate storage.

Advantages at a glance

- Easy and efficient storage technology for small to medium quantities of bulk materials such as wood chips and waste wood

- Ideal for boiler feeding in biomass power plants

- Fully automatic box evacuation without operating personnel

- Filling one or more boxes (up to 400 m³ each) using a semi-trailer, tipping scrap skips or wheel loader on even ground

- Discharge capacities of up to 100 m³/h

- Drive, lifting device, mechanical devices are outside of the bulk material and always easy to maintain

Convince yourself of the unlimited flexibility for unlimited requirements.

Intelligent storage of bulk materials with the Vecoplan Toploader

The patented Toploader system is the most economical storage technology for many bulk materials such as wood chips, waste wood, bark, RDF, corn, grass, pellets and plastics. The system also ensures fully automatic box discharging and thus efficient feeding.

PDF

|

3.51 MB

Product broschure storage and conveying technology

DOWNLOAD

Can be used for following material

Wood

Biomass

Paper and cellulose

Domestic and industrial waste

Alternative fuel

Plastics - post-consumer

Plastic - post-industrial

Plastic - Inhouse Recycling

All