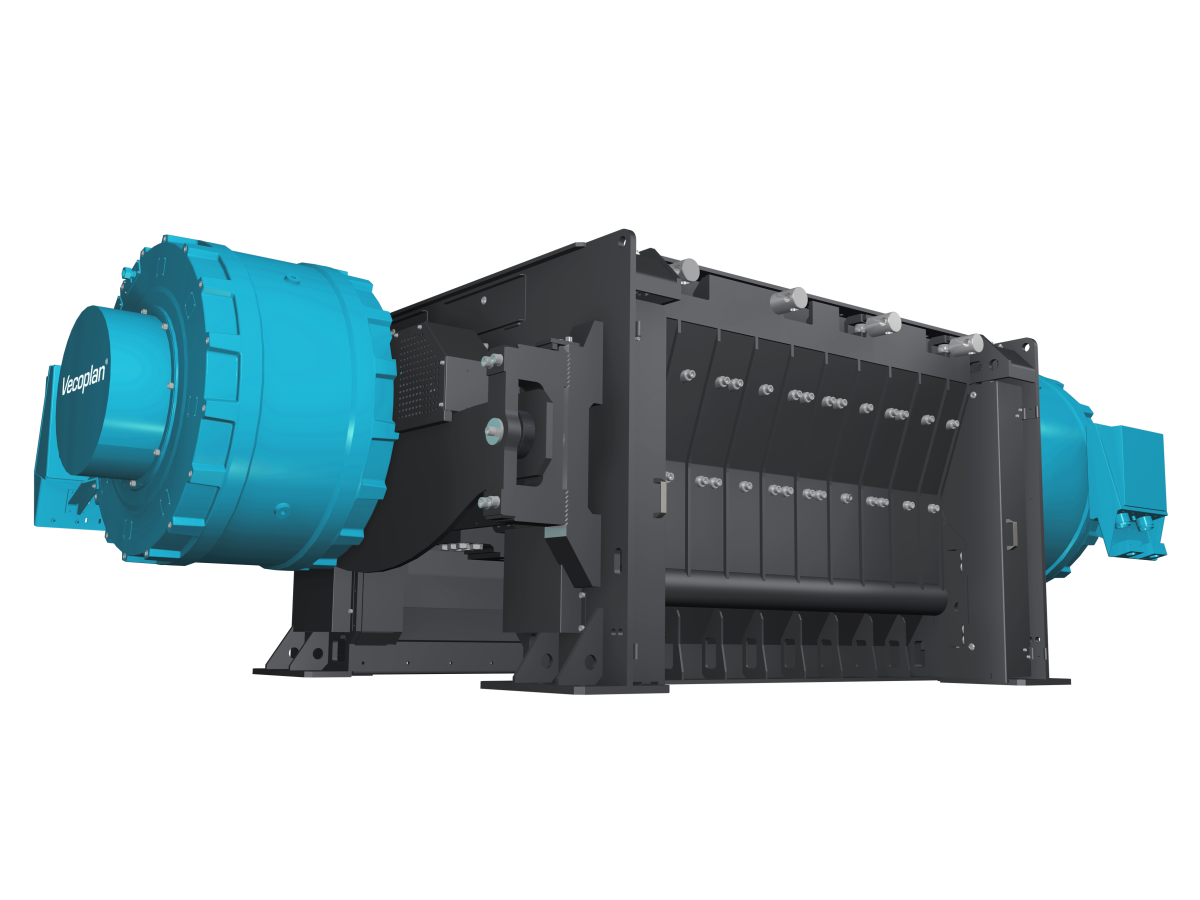

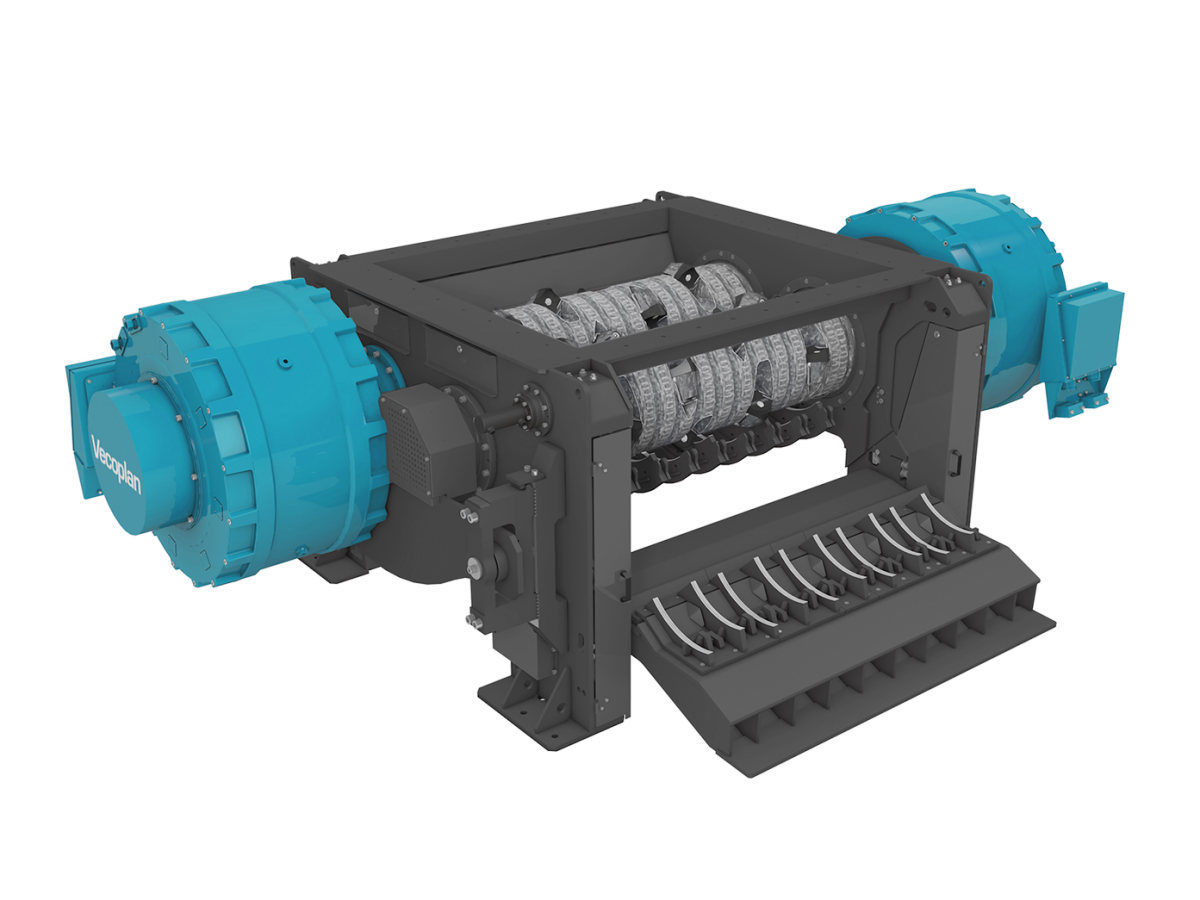

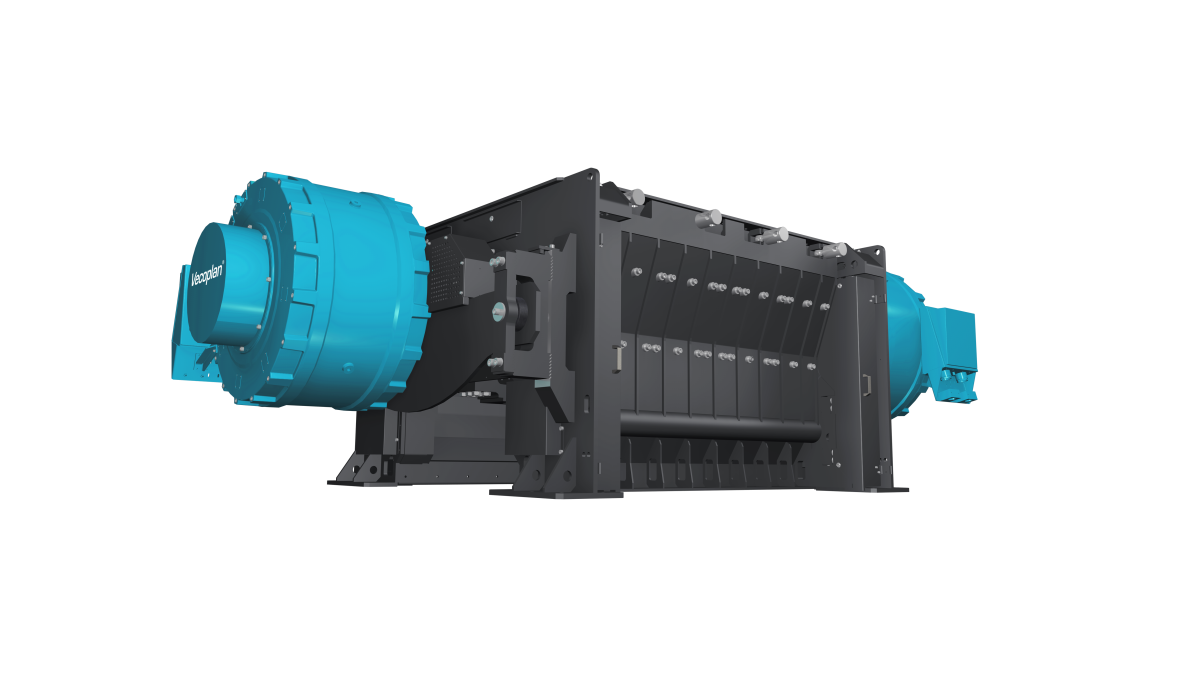

VVZ - Pre-shredder

Powerful and efficient – twin-shaft shredders for pre-shreddingWith the twin-shaft pre-shredder, almost any material can be shredded. The HiTorc drive saves energy and the contaminant detection reduces downtimes.

Maintenance and service costs are minimised by easily replaceable wear parts. The output material is characterised by the best homogenity,

optimally prepared for the next process steps.

VVZ - Double-shaft pre-shredder

The strongest among the double-shaft pre-shredders

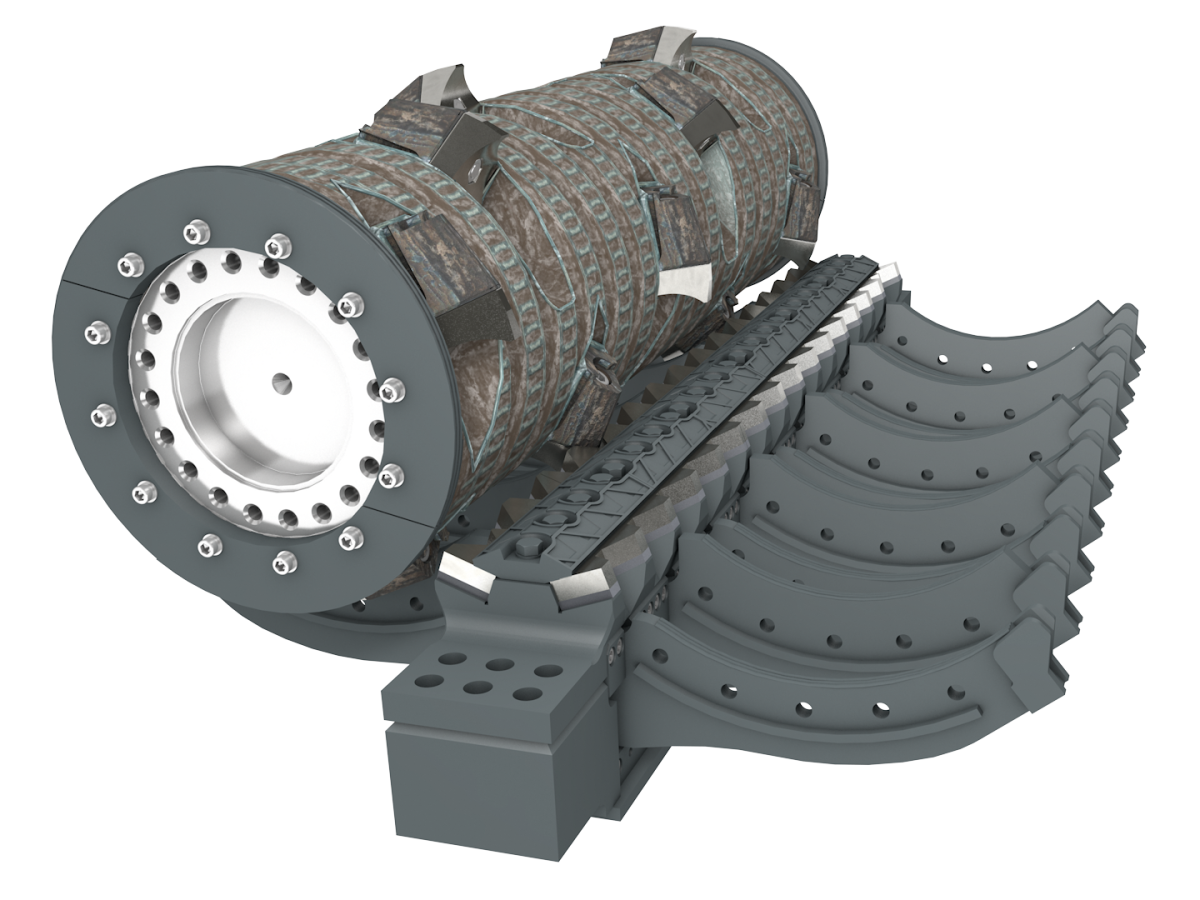

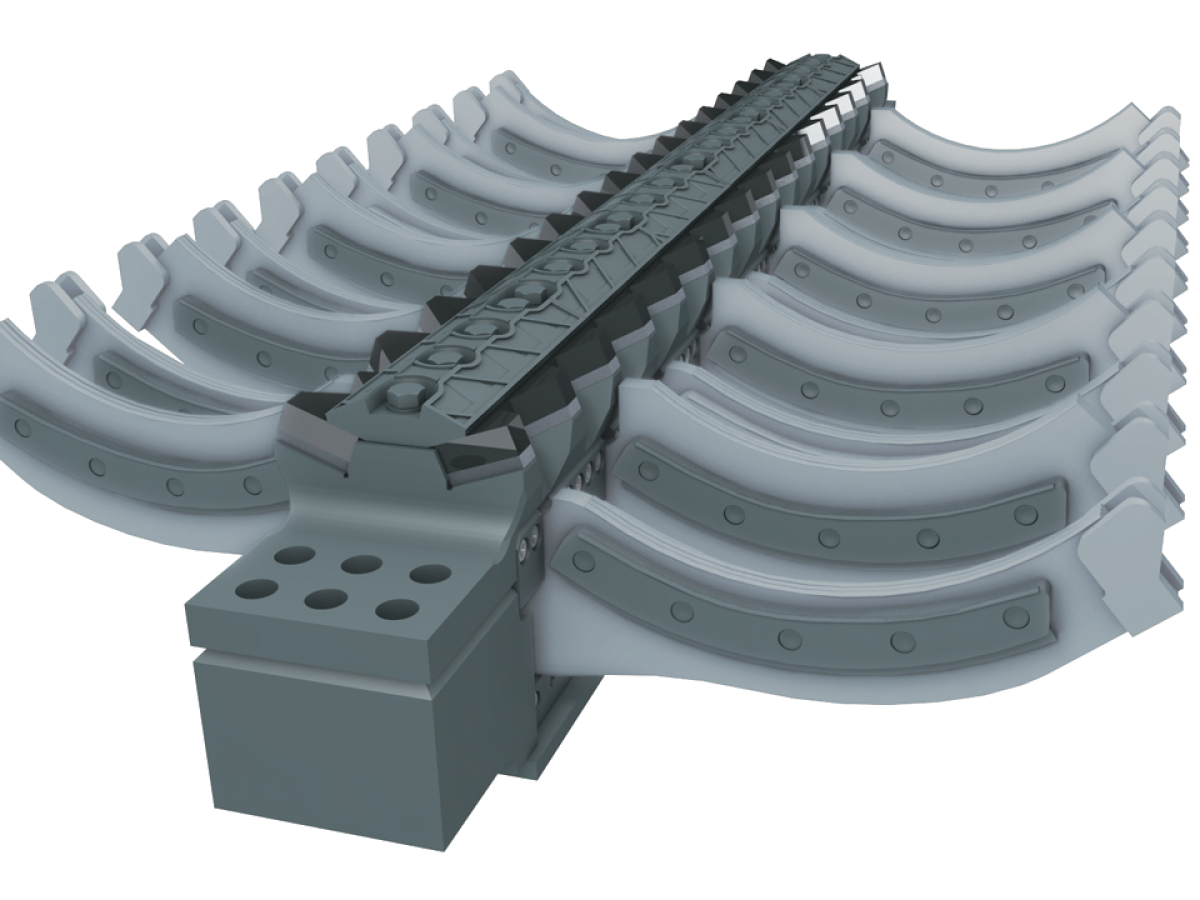

The Vecoplan double-shaft shredder is a pre shredder for difficult material and material containing extraneous materials, e. g. municipaland commercial solid waste, residual productionmaterials or wood waste, straw and root wood. With different cutting units, counter-knife variants and the specially adapted screen rod sizes, we can cater for the widest variety of input materials and customer requirements.

The highlights of the VVZ - Pre-shredder

Resilient power

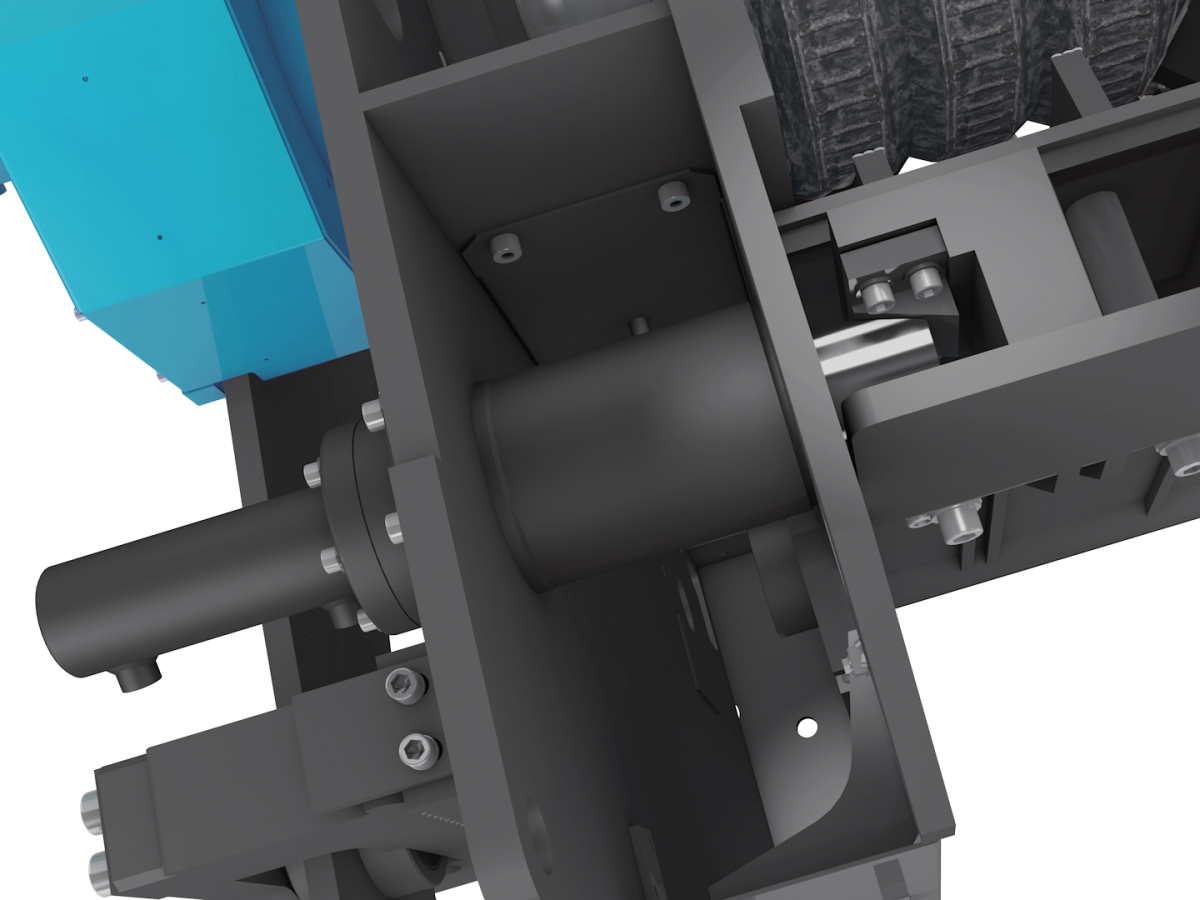

The machine housing is a thick-walled, ribbed construction with optimal functional machine geometry for powerful and trouble-free operation with a maximum service life. This means maximum and continuous availability over many years at the highest level. With their large flywheel mass, the two solid steel rotors ensure quiet machine running yet have a high cut-through power. The interplay of the two rotors with the same counter-knife combined with the screen rods produces a high separation quality and homogeneous output. The two large hydraulic maintenance doors make it easy to change wearing parts and allow taking out tramp material even if the hopper is completely full.

Your advantages at a glance

- Robust and durable design for extreme conditions

- Highest reliability and availability

- Cost minimisation through energy efficiency

- Best added value through consistently high, high-quality output

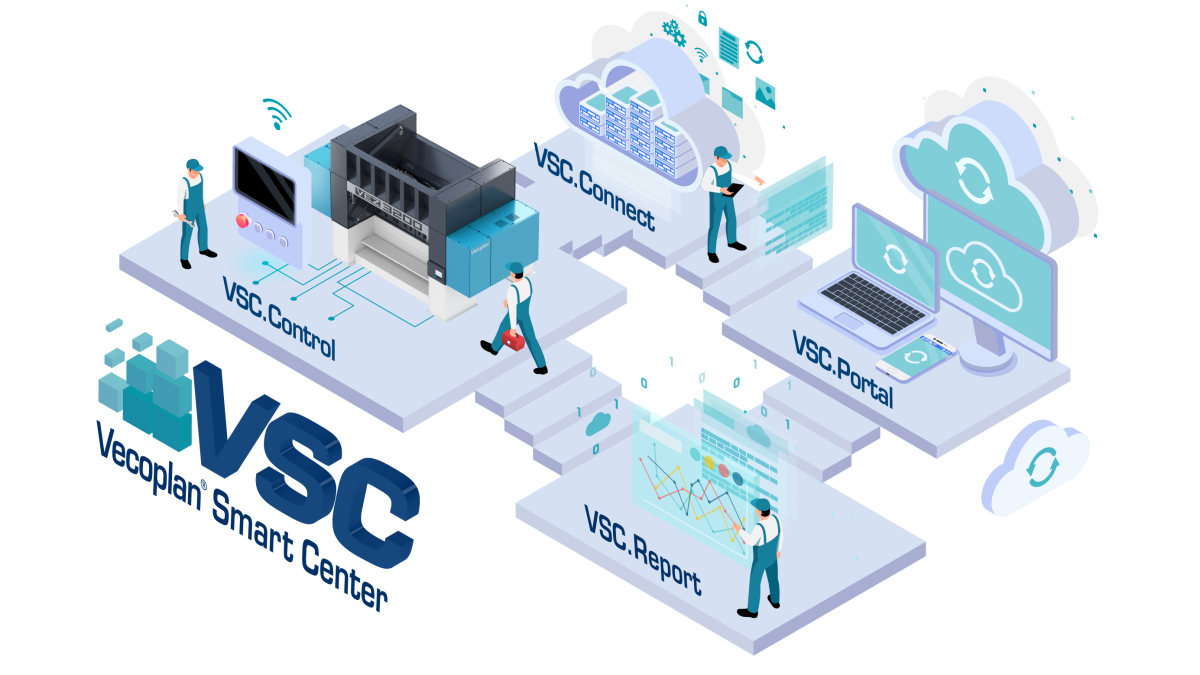

- Intuitive machine operation via VSC.control

- Online support and optimisation via the Vecoplan Smart Center

Which model suits your needs?

| Specification |

|

|

|

|

|---|---|---|---|---|

| Type of drive | Direct drive HiTorc | Direct drive HiTorc | Direct drive HiTorc | Direct drive HiTorc |

| Motor power | 2 x 155 kW | 2 x 155 kW | 2 x 155 kW | 2 x 155 kW |

| Speed range | 20 - 100 1/min | 20 - 100 1/min | 20 - 100 1/min | 20 - 100 1/min |

| Rotor length | 1,900 mm | 2,100 mm | 2,500 mm | 3,100 mm |

| Rotor diameter | 640-765 mm | 720 mm | 720 mm | 720 mm |

| Weight | 18.5 to | 22 to | 26 to | 31 to |

| Dimension (Length) | 4,960 mm | 5,160 mm | 5,560 mm | 6,160 mm |

| Dimension (Width) | 2,450 mm | 2,450 mm | 2,450 mm | 2,450 mm |

| Dimension (Height) | 1,750 mm | 1,750 mm | 1,750 mm | 1,750 mm |