VPC Pallet Crusher – Pre-shredding for Wood Pallets

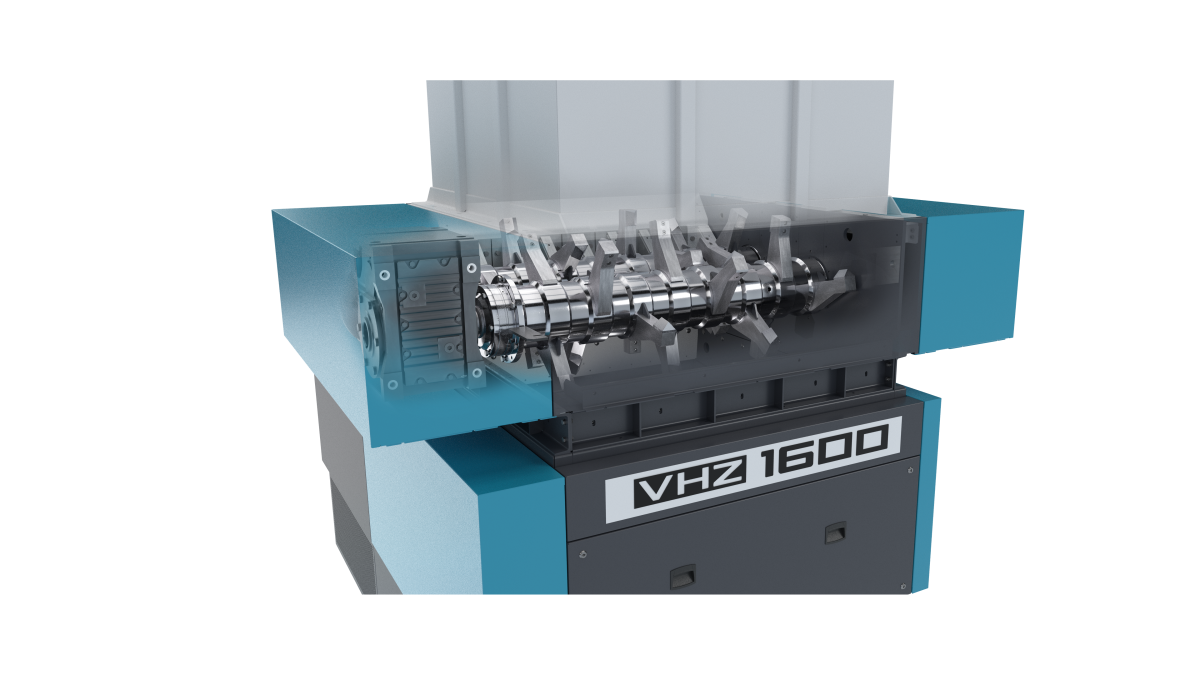

Optimal pre-shredding of large-volume and bulky components made of woodFor the pre-shredding of large-volume and bulky components such as boxes and pallets made of wood, we have developed the Vecoplan Pallet Crusher VPC 1600. This can be combined with the single-shaft shredder VHZ 1600, which then processes the pre-shredded material directly into homogeneous wood chips or briquette-ready material. This allows you to increase throughput by up to 50 percent. The special feature: In the VPC, the material is not cut, but crushed. This creates enormous advantages in the pre-shredding process and reduces the quantities of wear parts.

VPC - Pallet crusher

VPC 1600 - Fit for many different processes

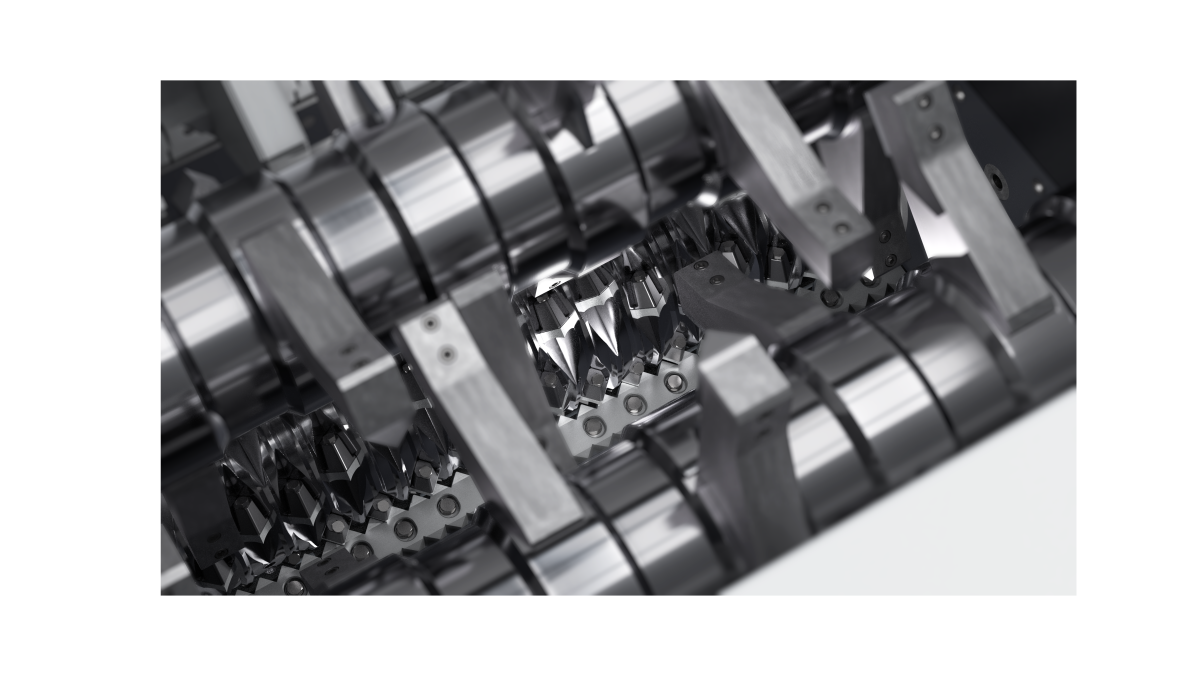

The Vecoplan VPC twin-shaft crusher is used for primary crushing of bulky wooden components such as pallets, crates & cable drums.The innovative rotors in the VPC 1600 pre-crush the wood before it is re-shredded by the cutting crowns of the VHZ rotor below.

The highlights of the new VPC - Pallet crusher

Combined solution of VHZ 1600 & VPC 1600

The VPC 1600 can be combined with the VHZ 1600 single shaft shredder. A sliding frame connects the shredder and primary crusher. This combined pre and re-shredding process increases throughput by up to 50 percent. The VHZ is compact, powerful and universal and can therefore be used for a wide range of residual wood shredding applications. Until now, it was necessary to select a correspondingly large machine for large and bulky components. The combined solution of VPC 1600 and VHZ 1600 achieves a high throughput with a small footprint and lower costs.

Your advantages at a glance

- Increase of the throughput capacity up to 50%

- Low maintenance costs

- Simple and fast maintenance work

- Small space requirement

- Reliable processing of large-volume feed material made of wood

Primary crusher for large-volume and bulky wood components

The Vecoplan VPC twin-shaft crusher is used for primary crushing of bulky wooden components such as pallets, crates & cable drums. It can be combined with the VHZ 1600 single shaft shredder. This combined pre and re-shredding process increases throughput by up to 50 percent.

Does this model suit your needs?

| Specification |

|

|---|---|

| Type of drive | Electromechanical drives |

| Motor power | 9,2 kW |

| Speed range | 10 1/min |

| Rotor length | 1,595 mm |

| Rotor diameter | 750 mm |

| Weight | 5.5 to |

| Dimension (Length) | 1,895 mm |

| Dimension (Width) | 3,125 mm |

| Dimension (Height) | 800 mm |