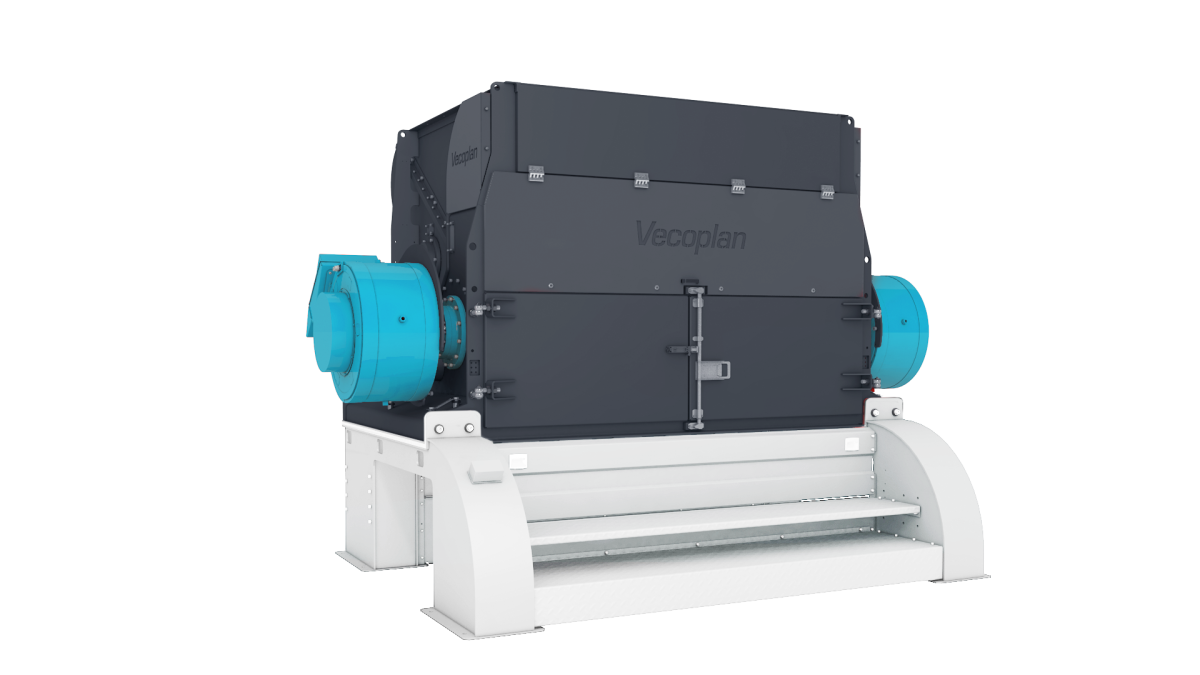

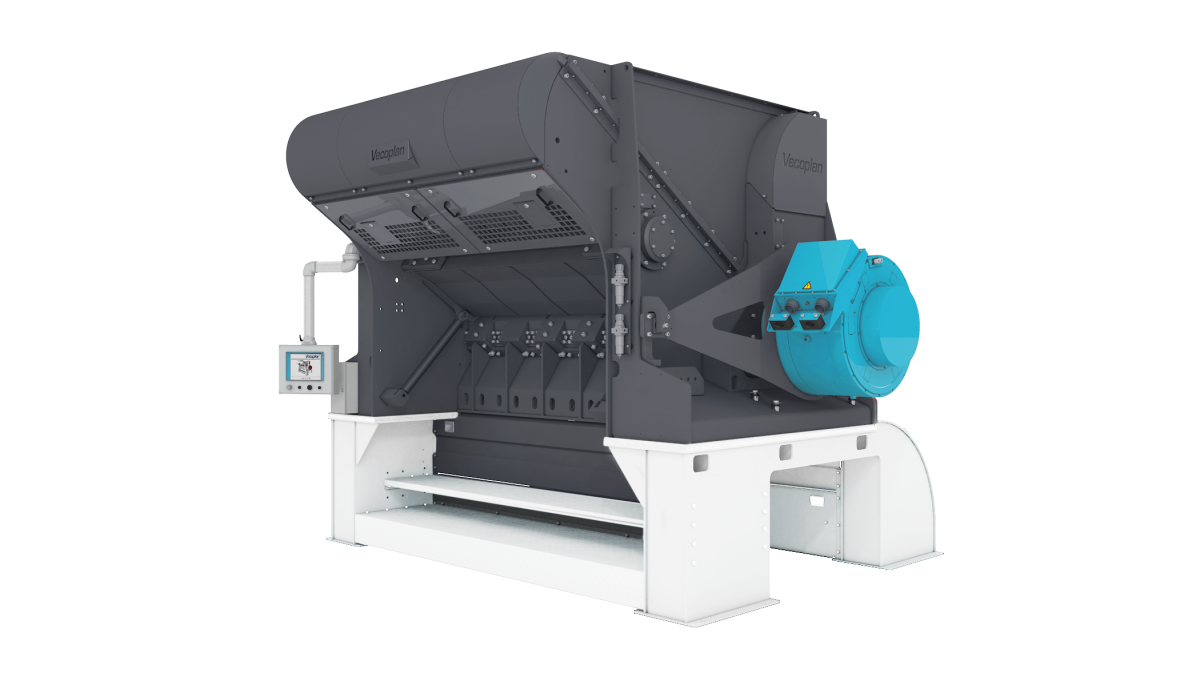

VEZ - RDF shredder (re-shredding)

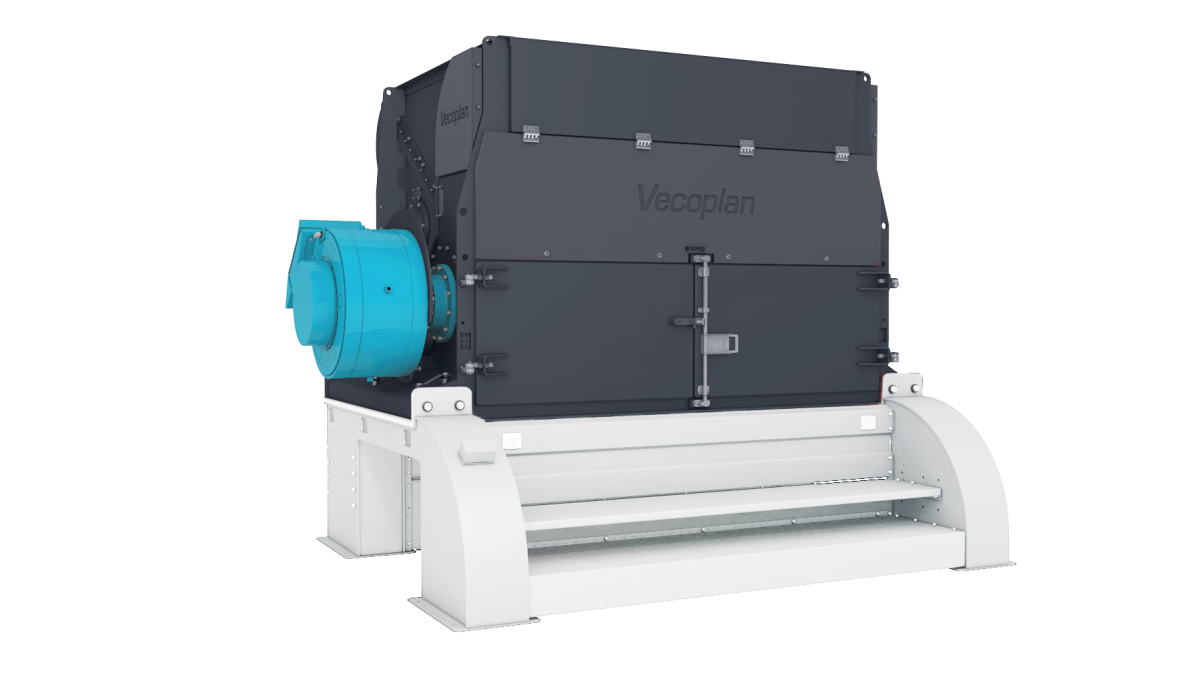

Series specially designed for the secondary shredding of domestic and commercial waste in the production of substitute fuelsA constantly high level of output quality is essential if materials such as production and sorting residues, packaging material and domestic and commercial waste are to be efficiently converted into energy in cement and power plants. The Vecoplan VEZ-T series and the VEZ-TT series with one and two HiTorc drives respectively are re-shredders designed to master these challenging tasks. Your production will benefit from a consistently secure process.

VEZ - RDF shredder

High-performance in RDF processing

The VEZ 2500 is the Vecoplan high-performance shredder specially designed for the production of alternative fuels from production and sorting residues, packaging materials and the high-calorific fraction from household and commercial waste for energy recycling in cement and power plants.

The highlights of the VEZ - RDF shredder

Pure shredding power

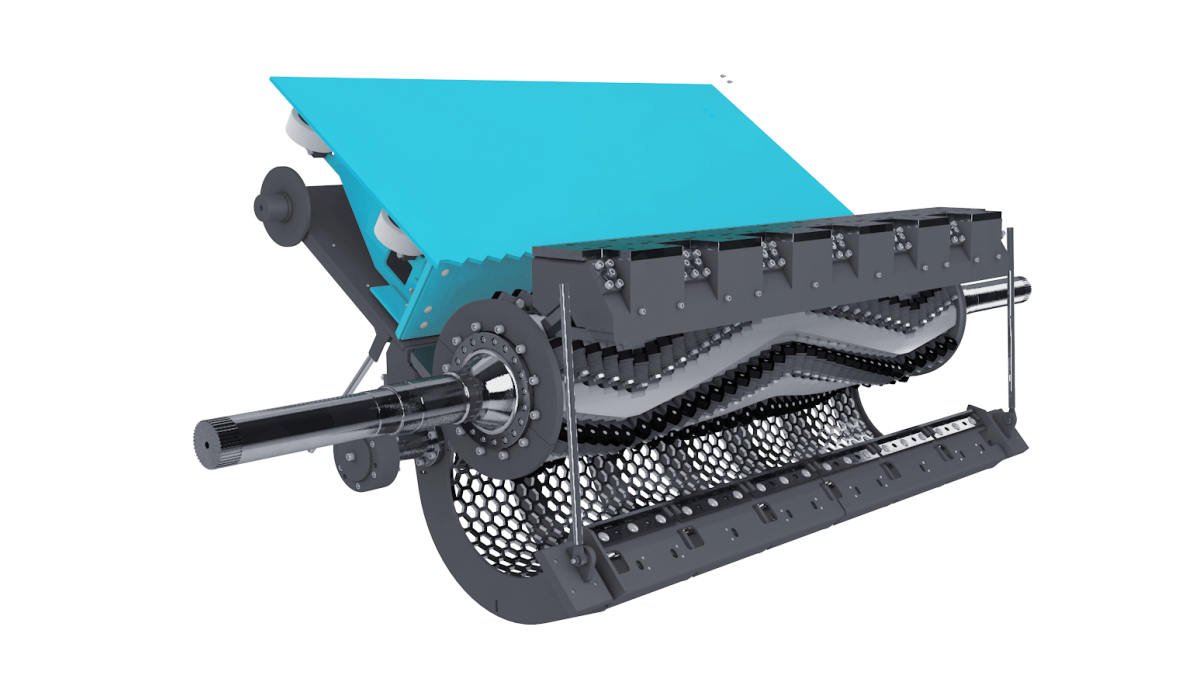

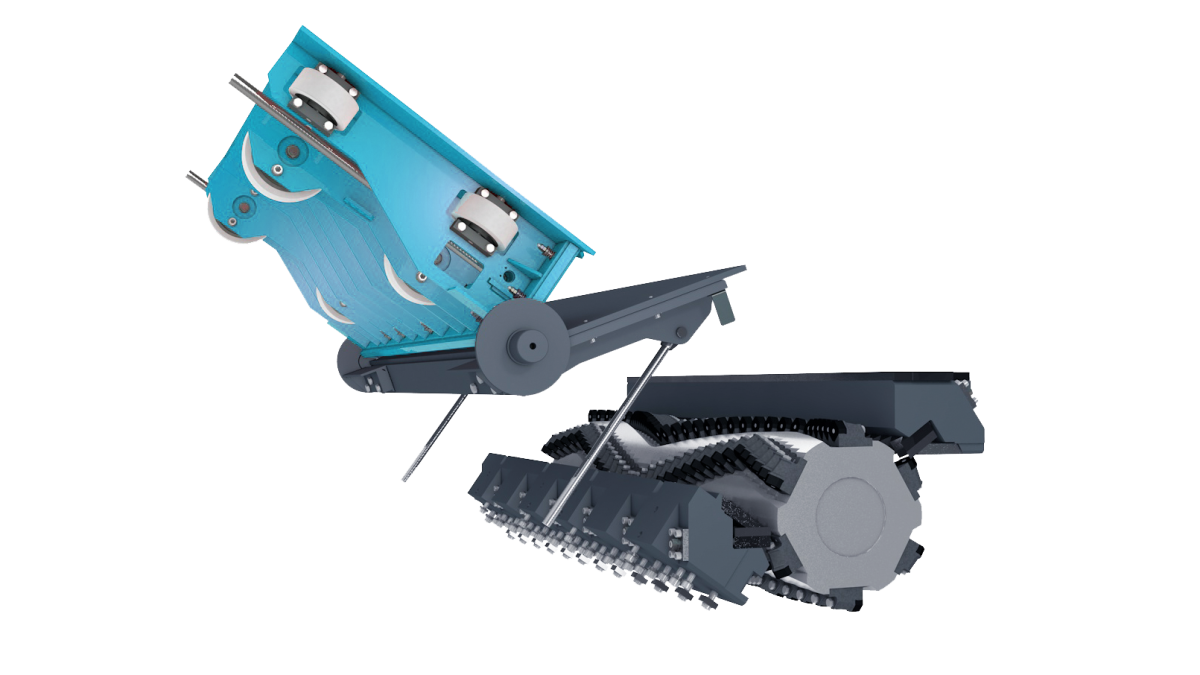

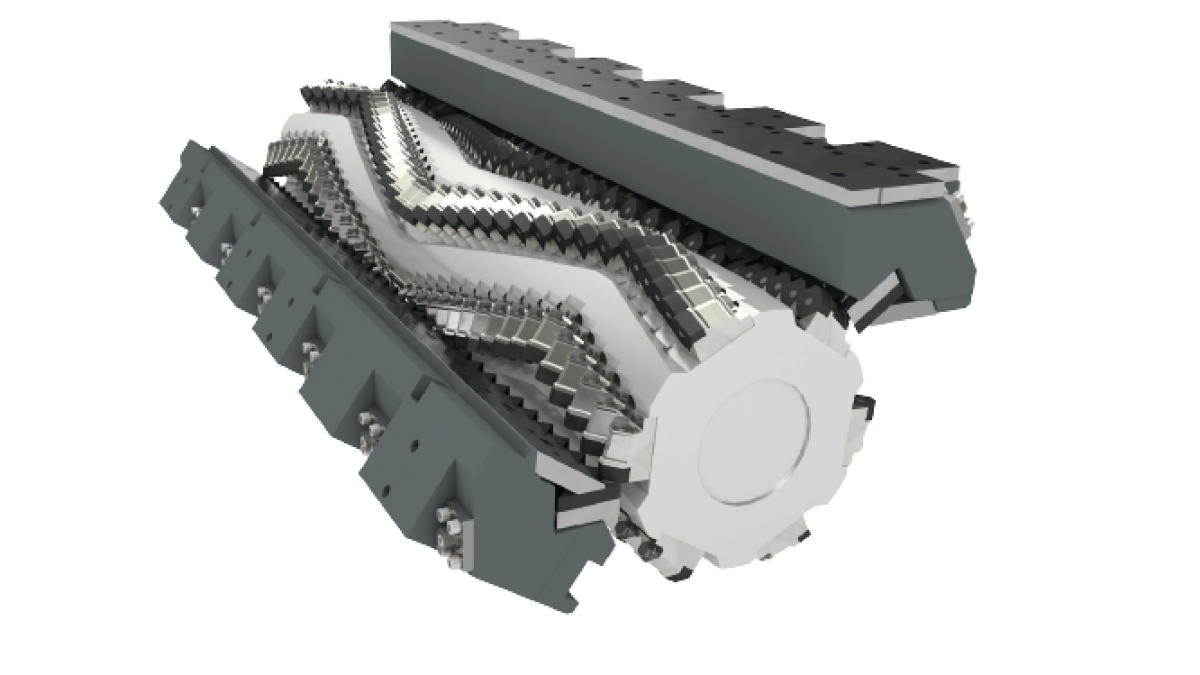

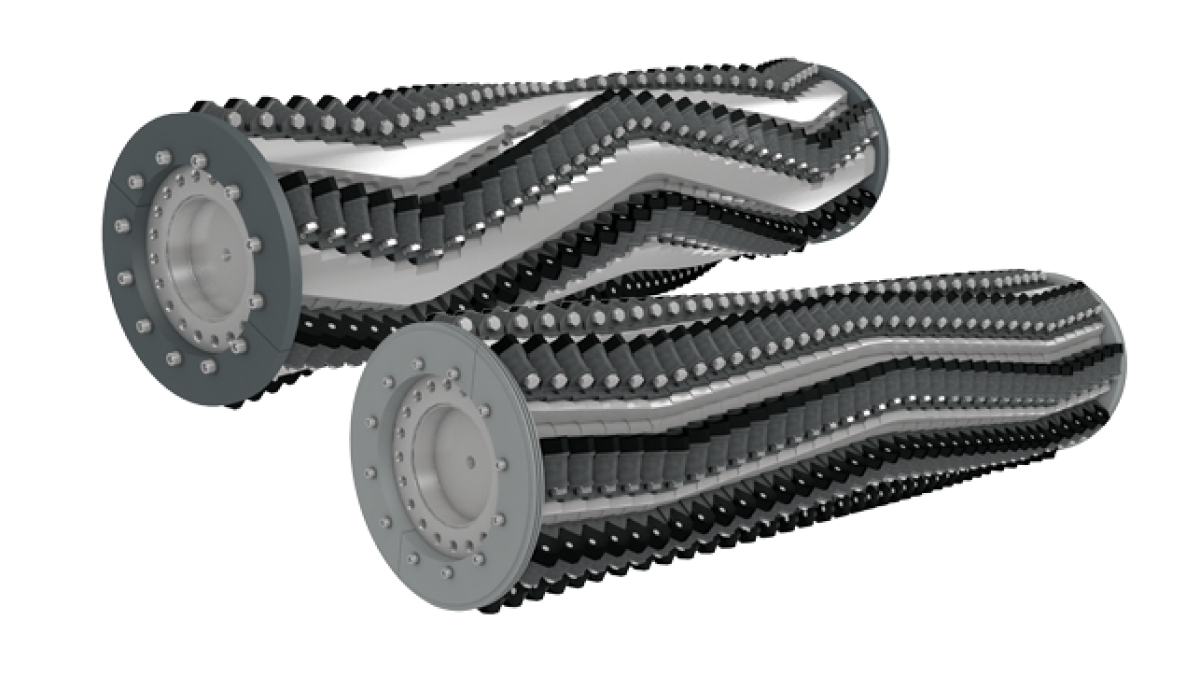

The VEZ 2500 T/TT uses the best Vecoplan technologies. The machine is excellently equipped and benefits from many clever details for re shredding. The HiTorc drive and the patented W-Rotor are systems developed by Vecoplan. We can therefore implement unique solutions for you in reprocessing alternative fuel, providing you with a clear competitive edge.

Your advantages at a glance

- Robust and durable design for extreme conditions

- Unlimited flexibility through various configuration options

- Highest reliability and availability

- Cost minimisation through energy efficiency

- Ergonomic machine design for optimum maintenance and service accessibility

- Best added value through consistently high and homogeneous output

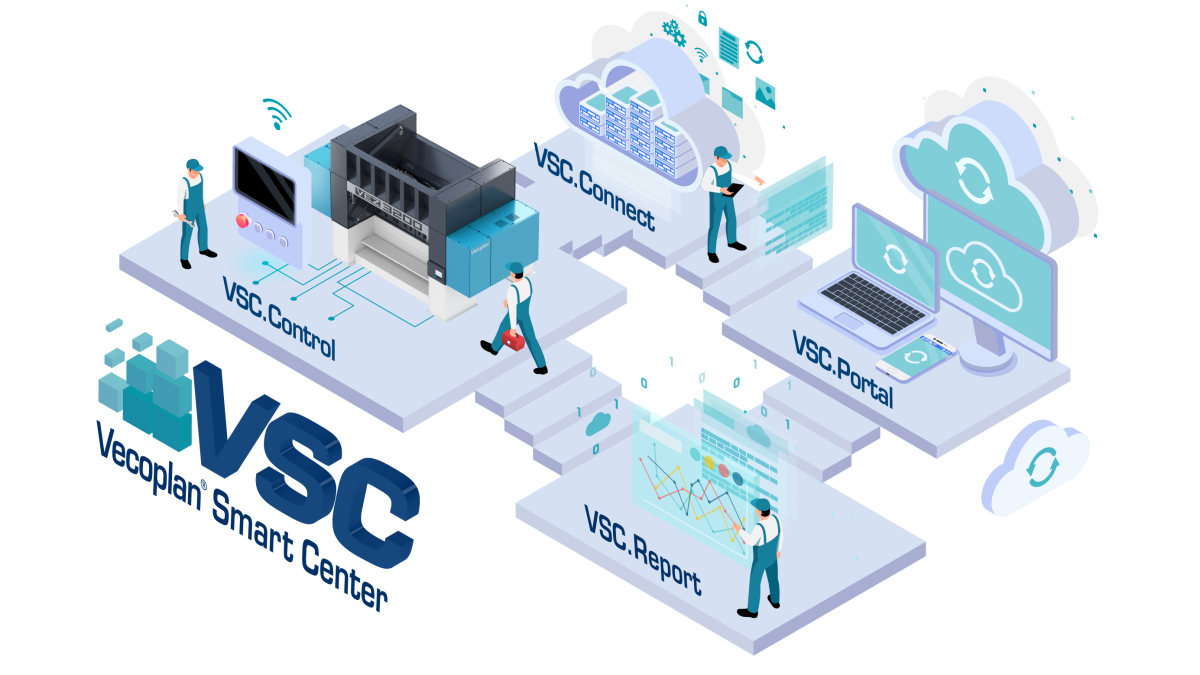

- Intuitive machine operation via VSC. Control

- Online support and optimisation via the Vecoplan Smart Center

Which model suits your needs?

| Specification |

|

|

|

|

|---|---|---|---|---|

| Type of drive | Direct drive HiTorc | Direct drive HiTorc | Direct drive HiTorc | Direct drive HiTorc |

| Motor power | 2 x 247 kW | 155 kW | 247 kW | 2 x 155 kW |

| Speed range | 150 - 420 1/min | 20 - 100 1/min | 150 - 420 1/min | 20 - 100 1/min |

| Rotor length | 2,500 mm | 2,500 mm | 2,500 mm | 3,200 mm |

| Rotor diameter | 640 mm | 800 mm | 640 mm | 800 mm |

| Weight | 22 to | 28 to | 20 to | 35 to |

| Dimension (Length) | 2,960 mm | 2,770 mm | 2,960 mm | 2,770 mm |

| Dimension (Width) | 4,940 mm | 5,790 mm | 4,300 mm | 6,490 mm |

| Dimension (Height) | 2,300 mm | 2,600 mm | 2,300 mm | 2,600 mm |