Machines used in recycling and production today have to perform better than ever before. Rising energy prices, variable materials, and growing demands for efficiency and operational reliability are increasing the pressure on operators.

With its digital platform Vecoplan Smart Center (VSC) and the new Vecoplan Intelligent Detect (VID) module, Vecoplan offers a solution that protects processes, lowers costs, and reduces downtime.

Advantages at a glance

- Up to 60% less risk of damage thanks to intelligent vibration detection

- Up to 70% fewer machine delays

- Self-learning material detection with automatic "recipes"

- Fewer repairs, lower tooling costs, shorter downtimes

- Seamless integration into new and existing systems

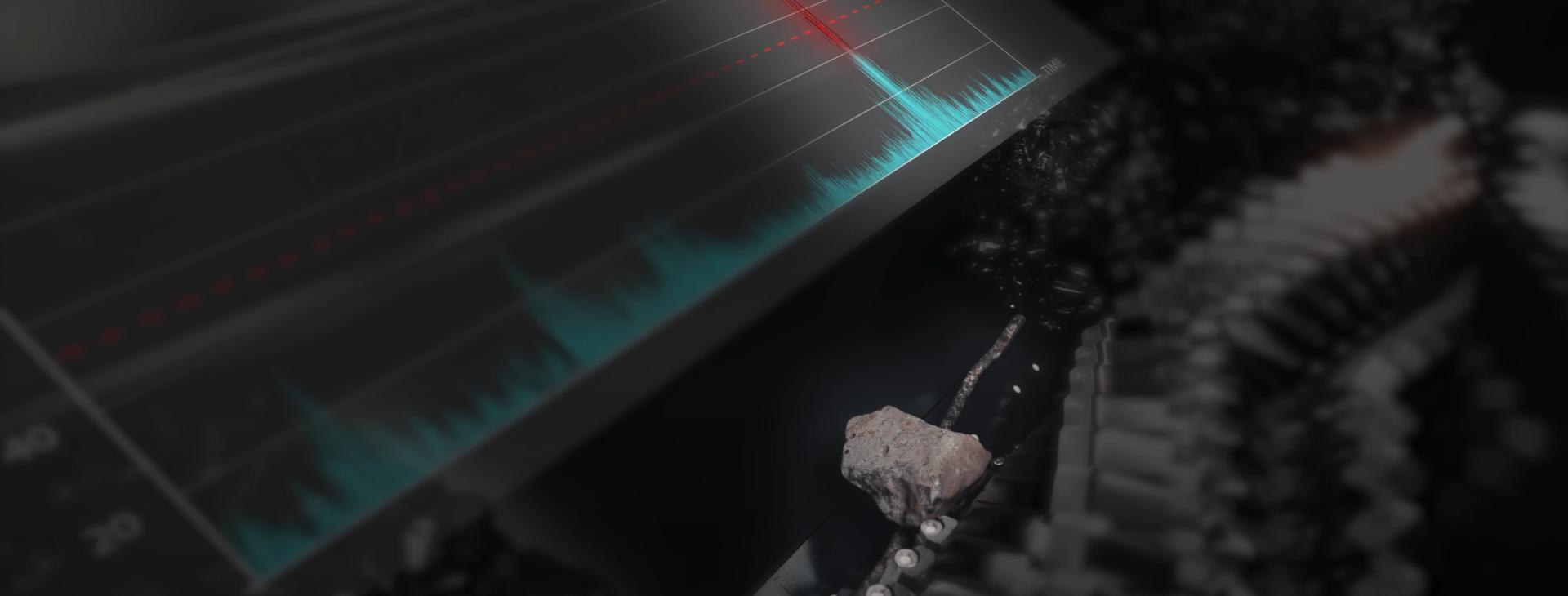

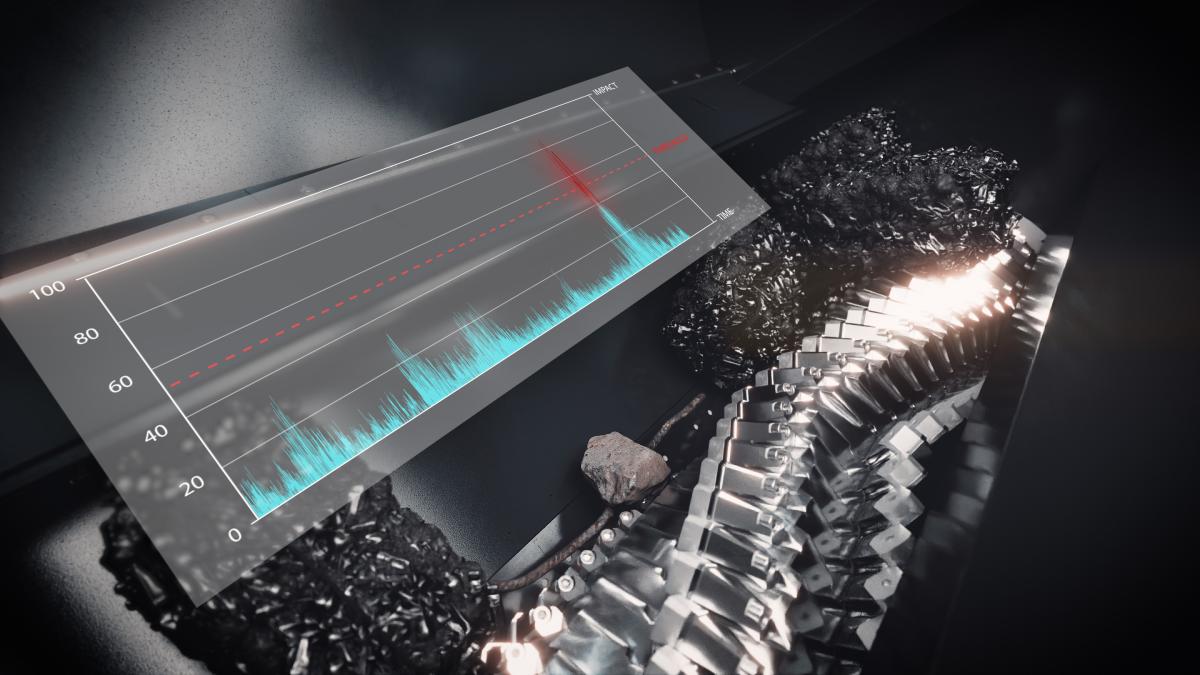

How the Vecoplan VID works

Instead of merely predicting failures, VID reacts directly during operation:

- Sensors detect even the smallest vibrations at high frequency.

- The system compares this data with material-specific threshold values.

- In case of danger, it intervenes immediately – from the rotor brake to machine shutdown.

Ultimately, this means one thing above all else for our customers: more relaxed production and cost savings.

Recipes for every material – the self-learning system

VID automatically adapts to new materials:

- When a new batch of material arrives, it analyzes the vibration values for a few minutes.

- It independently sets an individual threshold value.

- Programs can be saved and recalled at the touch of a button using “recipes.”

Whether it's lightweight films, hard plastics, or a new machine configuration, VID remains flexible and reliable.

The Vecoplan Smart Center bundles all relevant data in a digital platform: speeds, performance values, slider movements, vibration profiles, and foreign object reports. This gives users full transparency and allows them to monitor, adjust, and even remotely control machines in real time.