Requirements

A maximum reliability, efficient use of energy and undisturbed supply of the biogas plant as well as the provision of the required storage volume and the provision of the required high discharge capacity during the feeding cycles.

Solution

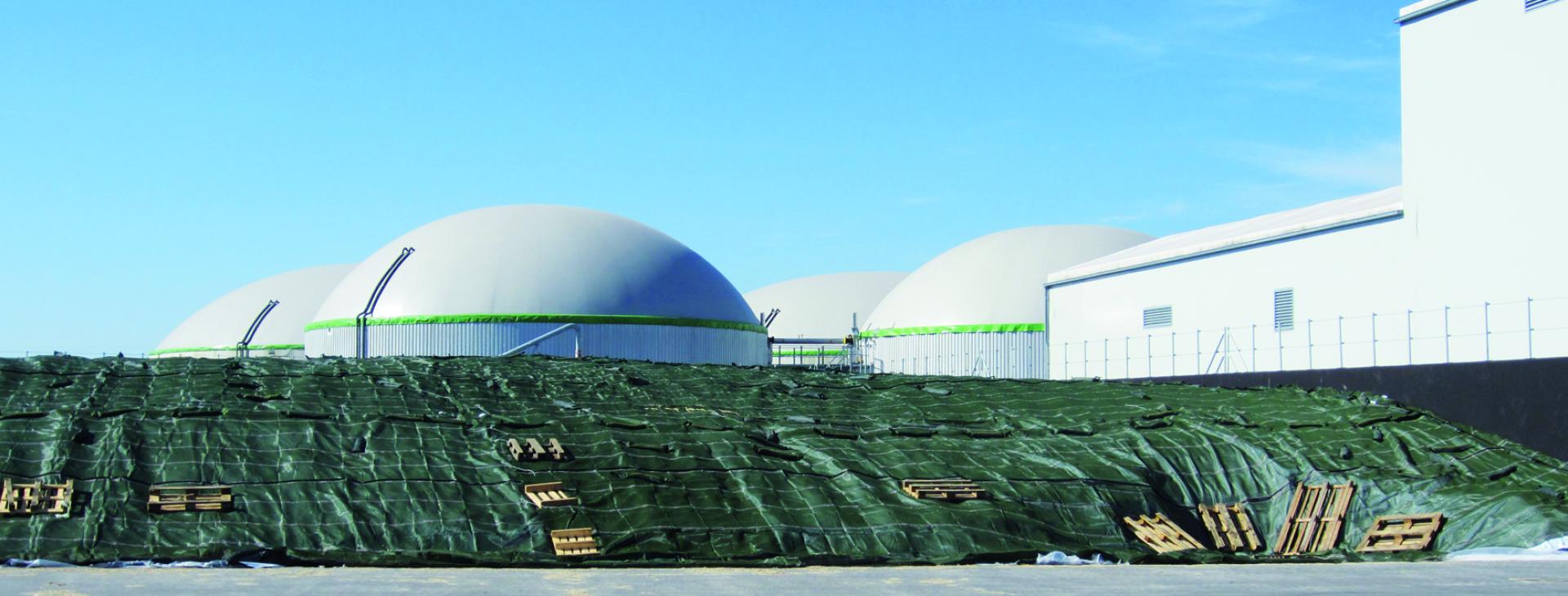

To ensure undisturbed reliable feeding of the biogas plant, Vecoplan designed an efficient and energy-saving solution for receiving, storing and dosing the substrates as well as subsequent feeding of the biogas plant. Two toploaders, three conveyor belts and a fully automatic control system are used.

Result

The customer benefits from an efficient and energy-saving solution. Substrate intake takes place just-in-time during the ongoing process. In addition, both the material storage and the feeding of the biogas plant run automatically.

Smart storing for bulk materials with the Vecoplan Toploader

The patented Toploader system is the most economical storage technology for various bulk materials like wood chips, old timber, bark, RDF, corn, grass, pellets and plastics. The system also provides for fully automatic box evacuation and so it is the perfect solution for feeding processes.

We couldn’t be more convinced to have chosen the Vecoplan toploaders and are already planning to acquire more for future projects.