Requirements

In 2011, GELO and Stadtwerke Wunsiedel founded WUN Bioenergie GmbH, which produces renewable energy from regional wood in a biomass cogeneration plant. Wood chips are supplied to the pulp industry and sawdust is processed into pellets for electricity and heat. To facilitate further growth, GELO built the GELO Timber sawmill in neighbouring Wunsiedel. This is a modern small sawmill. The waste wood is efficiently processed into wood chips or pellets.

Solution

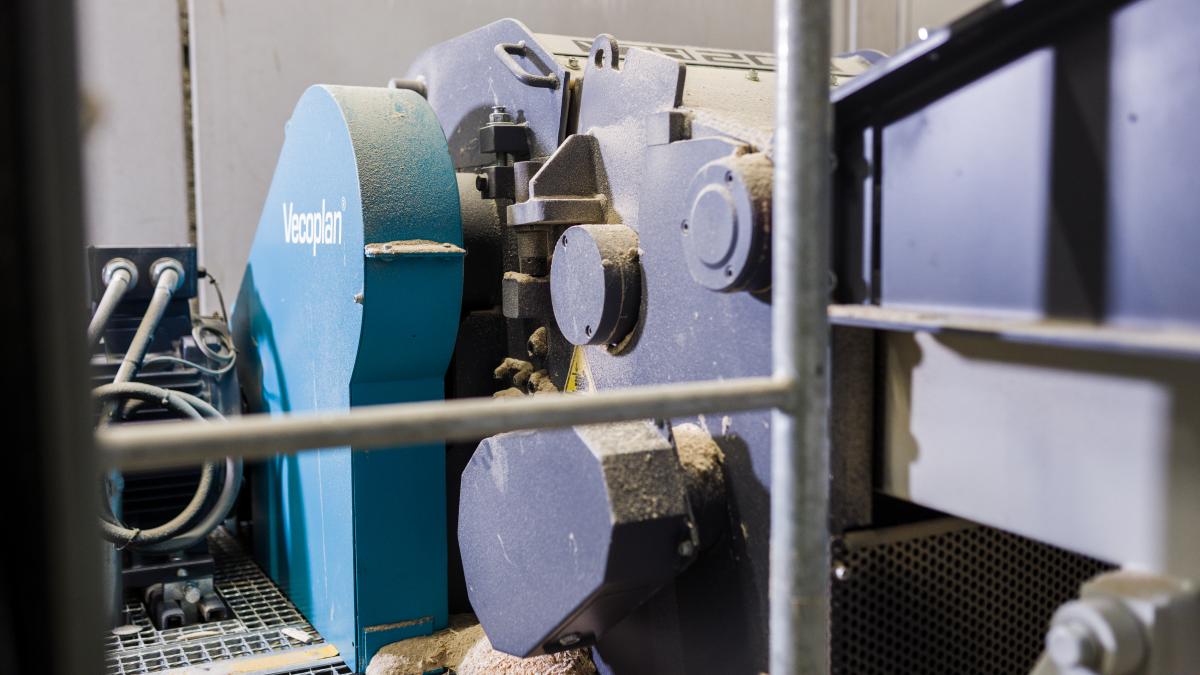

Vecoplan, a specialist in the processing of waste materials, supplied the required shredding and conveying technology. The systems, which have been planned since January 2020 and will be delivered in summer 2020, are designed for a chipping length of around ten millimetres in order to prepare the waste wood for pellet production. Vecoplan's pipe belt conveyor system ensures energy-efficient, closed-loop material transport.

Result

Thanks to the short transport routes and efficient technology, GELO is able to save a significant number of truck journeys. Despite the challenges posed by the coronavirus, regular operations started at the end of February 2021. Wolf-Christian Küspert, owner and managing director of GELO Holzwerke, emphasises that successful projects need reliable partners and praises Vecoplan's continuous support and expertise.