Shredding

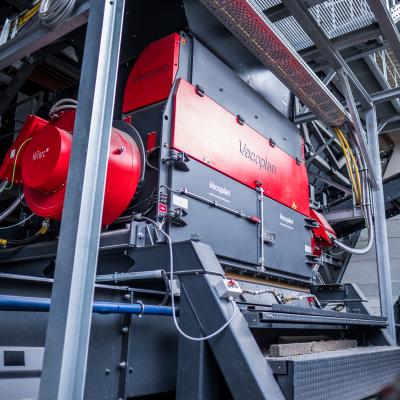

Our core competence in the preparation of residual materials for further processing and recyclingVecoplan is the market leader for the shredding of residual materials and preparing them for downstream material or thermal processing. We have a wide range of products from which we will select the right machine to perfectly match your specific input material. For example, this applies to a wide variety of plastics, but also to different types of wood. There are also very different types of waste, which are often interspersed with impurities. You can process these waste types for RDF production. We will work closely with you in all your usage scenarios. Our shredders will give you the output that meets your high efficiency and quality requirements.

What material do you want to shred?

Find the right shredder for your material with our intelligent filter option!

Get the best out of everything

Whether it’s wood, biomass, plastics, paper, domestic or industrial waste, or even data carriers – we develop innovative concepts and convincing solutions to efficiently process materials that frequently differ greatly from one another. You will always get the best possible solution from us, even for the most difficult tasks.