Two key questions are driving the industry:

- how can energy consumption and operating costs be reduced without sacrificing performance?

- how can system availability be kept high, even with changing materials and intensive use?

The answer to these questions lies at the heart of the machine - in the drive. And this is precisely where we at Vecoplan come in with a real innovation.

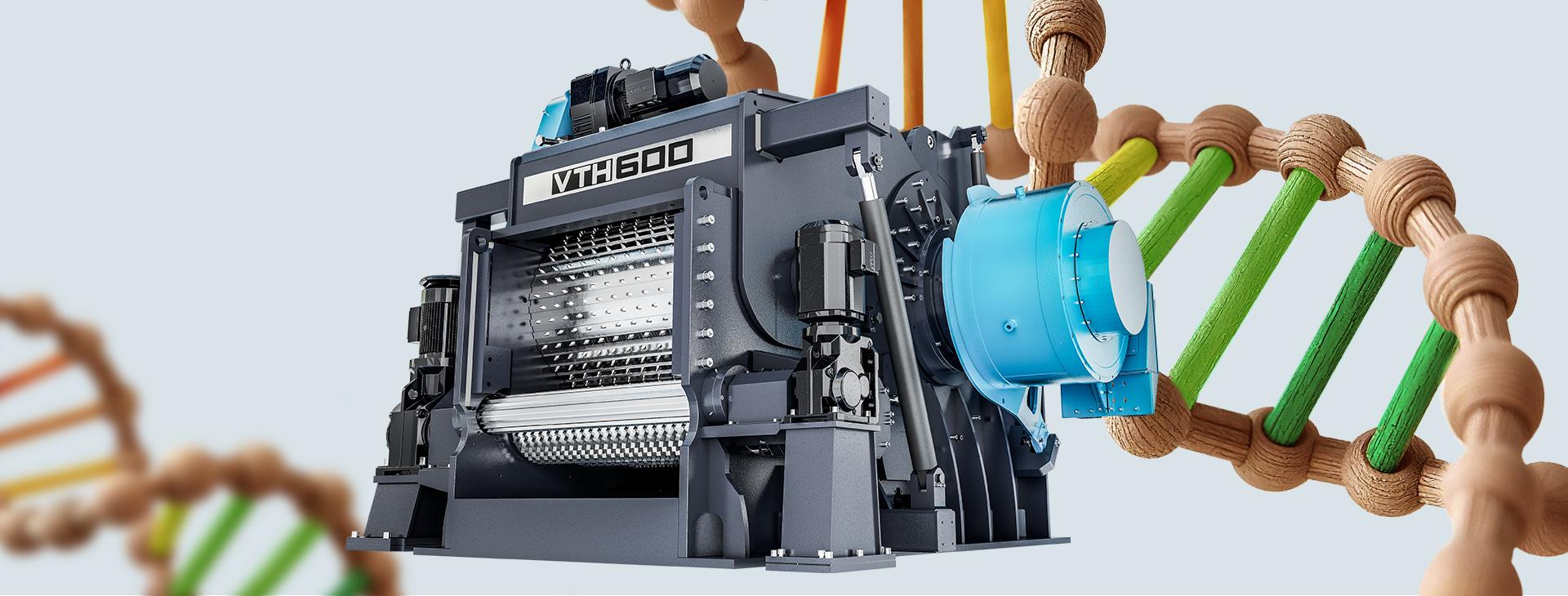

With the new VTH 600-1050 BT from Vecoplan, we have launched the first energy-efficient biomass chipper on the market that works with our proven HiTorc direct drive. The HiTorc technology, which has already proven to be extremely powerful, durable and energy-efficient in single and twin-shaft shredders, is now being used for the first time in a high-speed machine for the wood industry.

‘We have set a real milestone with this,’ says Dirk Müller, Vice President Wood | Biomass at Vecoplan. ‘Performance, efficiency and digitalisation - this machine combines all of these in a new dimension.’

What makes the HiTorc from Vecoplan so special?

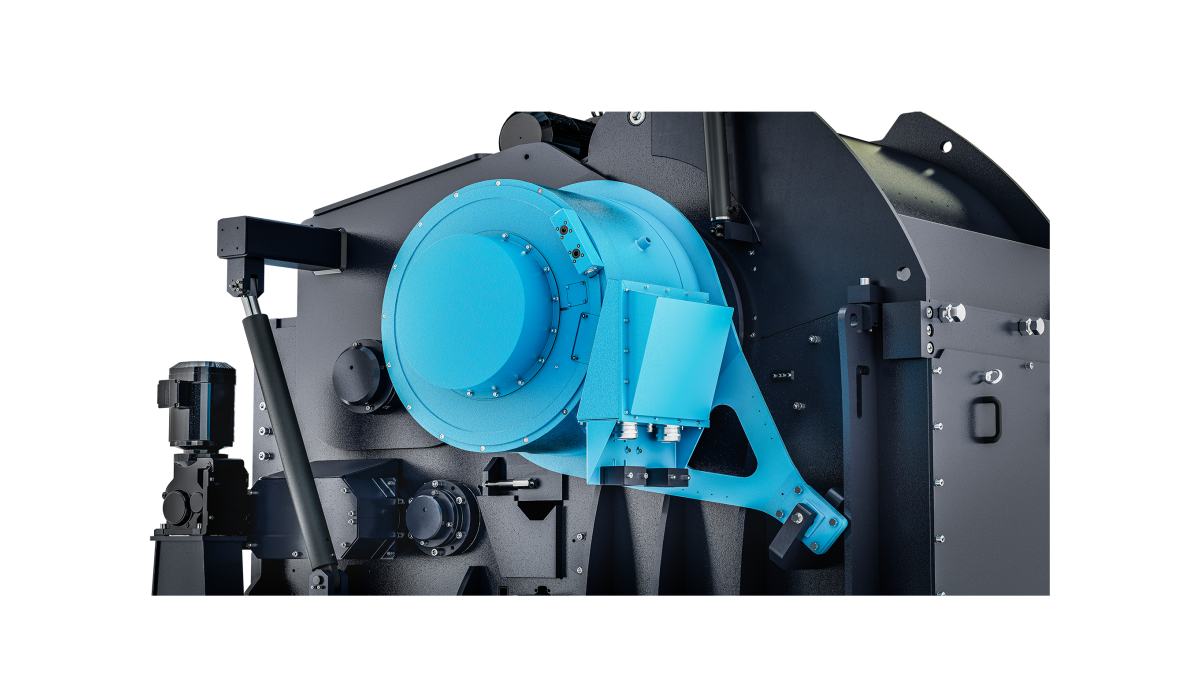

The HiTorc drive completely replaces classic mechanical components such as:

- belts

- clutches

- gearboxes

Instead, the motor transmits the torque directly to the rotor shaft - precisely, quickly and without energy losses. The direct drive thus saves space, reduces wear and, above all, ensures one thing: extremely high efficiency.

In concrete terms, this means:

- Up to 40 % less energy consumption compared to conventional drives

- Maximum torque of up to 80,000 Nm

- Full power in just three seconds

- Only 10 % of the idling energy of a standard motor

The HiTorc really exploit his strengths in the partial load range, which often occurs in practice:

The motor automatically and efficiently adapts its power to the demand -

without any mechanical energy loss.

HiTorc: Flexible performance for every application

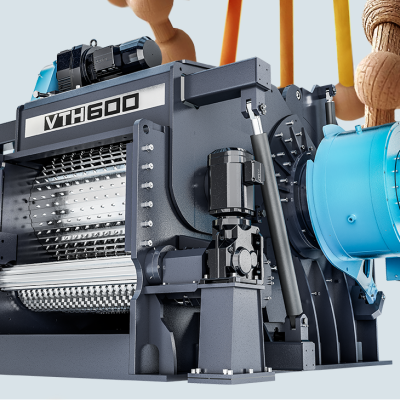

Despite its technical complexity, the VTH 600-1050 BT remains easy to integrate. The compact design significantly reduces the space required and the installation effort - even in confined areas. Due to the fact that there is no need for installing heavy belt or gear systems, elaborate foundation work is no longer necessary.

The HiTorc range of applications? Versatile and flexible:

- Energy and pellet industry

- Biomass cogeneration plants

- Chipboard industry

- Sawmills and waste wood processors

Regardless of whether the material is coarse or fine -

the machine adapts quickly to new requirements thanks to the simple adjustment of the rotor parameters and cutting tools.

Digitalisation included: the Vecoplan Smart Center (VSC)

At Vecoplan, modern technology does not end with steel - it continues digitally. With the Vecoplan Smart Centre (VSC), we offer a solution that turns the new chipper with HiTorc direct drive into a networked and intelligent machine.

At the heart of the digital concept are two harmonised components. The first is the VSC.control - an intuitive touch control panel that provides the operator with a clear, easy-to-understand interface to the machine. The panel can be used to centrally control all functions, adjust parameters and monitor ongoing operation in real time.

Secondly, VSC.connect, the cloud-based online platform from Vecoplan, ensures a seamless digital connection. It provides access to remote functions such as remote maintenance, monitoring of relevant key performance indicators (KPIs) and digital documentation. This gives operators an insight into the condition of the machine at any time and from any location, allowing them to react quickly if necessary.

This intelligent networking brings numerous advantages in everyday life. For example, the system uses integrated sensors and vibration monitoring to recognize signs of impurities in the material flow at an early stage. Maintenance work can also be planned efficiently as the machine continuously monitors its own condition. Expensive downtimes can therefore be minimized. If technical support from Vecoplan is nevertheless required, this can be carried out remotely in many cases - without any travelling time or maintenance work. This saves costs, time and significantly increases system availability.

‘The VSC ultimately saves time, money and nerves,’ says Dirk Müller. ‘

With the help of the Smart Centre, the machine recognizes early on if something is wrong - and immediately suggests countermeasures.’

Resistant to interference and low maintenance: more availability, less downtime

Machine downtimes due to worn belts or defective gearboxes are a thing of the past. The elimination of classic wear parts drastically reduces maintenance costs. At the same time, availability increases - a real benefit for every system operator in key industries.

The HiTorc also shows its strengths in the event of a fault:

- Foreign material detected? The rotor stops in a flash.

- No manual intervention necessary: the machine reverses automatically.

This combination of intelligent technology, strong performance and high safety is unique in this machine class.

More than just a chipper - a new chapter in shredding technology

The new VTH 600-1050 BT with HiTorc direct drive from Vecoplan is characterized in particular by its combination of innovative direct drive, digital intelligence and proven mechanics.

Anyone looking for energy efficiency, high availability, simple maintenance and smart operation will find a future-proof solution in this model - economical, energy-efficient and technically sophisticated.

‘For us, the VTH 600-1050 BT is more than just a product - it is a clear statement of innovation and progress in the industry’ - Dirk Müller

Would you like to find out more?

We will be happy to advise you on possible applications, potential savings and technical details.

Contact us now or request further information about the HiTorc.