“The VSC includes the VSC.control operating panel,” explains Bastian Wienen, Regional Sales Manager in the Recycling | Waste division at Vecoplan. This is the communication medium for the modern control system.” However, the VSC is much more than just an operating panel. Wienen adds, “It’s the heart of our modern machine control system and the main interface between the operator and the machine – and it connects directly to our service network.” Its robust design also makes it ideal for use in harsh environments – in waste management, for instance, and the intuitive user interface greatly simplifies operation. Various tasks can be handled simultaneously by the communication interface and parallel navigation.

The VSC.control is also extremely flexible. It can either be installed in switch cabinets or used as a standalone control panel. “This allows us to offer our customers various configurations tailored to their specific needs,” emphasises Wienen. “Many of our machines already come with the VSC.control integrated as standard, but users can also retrofit their existing systems with this advanced control system – and profit from cutting-edge technological advantages.”

Meeting specific requirements

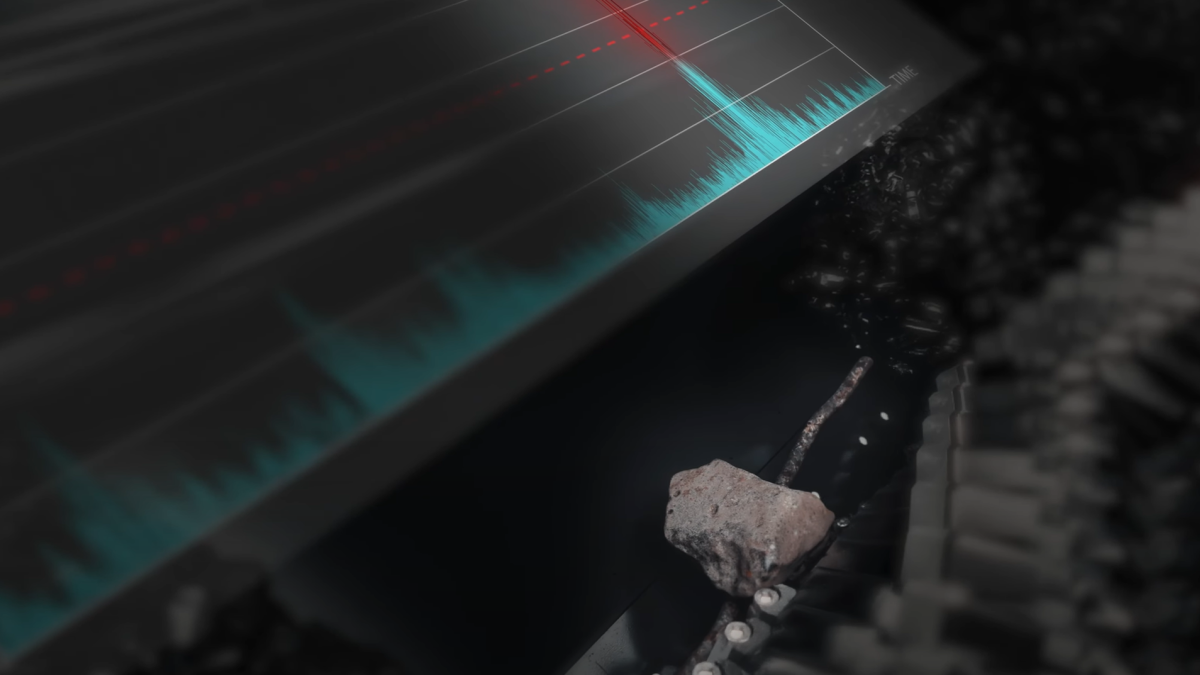

The VSC’s second component is the VSC.connect, a platform that offers a range of smart tools specifically developed by Vecoplan to improve the efficiency and ease of maintenance of its machines. With VSC.connect, customers can connect their systems online and access even more services. “Our remote service enables our specialists to diagnose and solve problems from our offices,” says the Vecoplan expert. “This minimises shredder downtimes.” System start-ups can also be carried out online, simplifying the commissioning of new machines. Customers can additionally monitor their key performance indicators (KPIs), maximising productivity and minimising downtimes. A media database also provides users with extensive information and documentation, making the machines easier to operate and maintain. Tutorials are also available to operators. They explain tasks such as changing cutting tips and adjusting counter knives in a simple, visual format. “These two components work together to ensure a high level of efficiency and the best possible operating conditions,” says Bastian Wienen.

The Vecoplan Smart Center offers a comprehensive dashboard that displays all the relevant information in real time. Users can also access historical data, perform detailed analyses and optimise the operation of their machines. Thanks to integrated cameras, they can carry out visual inspections without having to be on site. All of these functions dovetail perfectly with one another, providing users with a complete overview of their systems – and making system monitoring and control much easier. Machines equipped with the VSC also assist plant operators by sending notifications about malfunctions or warnings about possible problems directly to the digital devices of the machine operator and the production manager.

Flexible financing

Vecoplan now offers its customers flexible financing models. “We understand that investments in new technologies and systems can represent a significant financial burden,” says Wienen. “That’s why we offer our customers tailored leasing models and flexible financing options like pay-per-use.” This enables customers to operate their machines according to demand, paying only for the actual usage. This is particularly advantageous for companies with seasonal fluctuations or irregular demand, because they can benefit from our solutions without jeopardising their liquidity.

Expanded service portfolio

In addition to providing more comprehensive digital services, Vecoplan has also expanded its service portfolio. The company is now offering various maintenance packages that are specifically tailored to meet the needs of customers. These programmes help to protect investments through continuous and preventative measures. “We keep our eyes on the machines and systems and do everything in our power to prevent costly failures and necessary service interventions,” says Wienen. “This optimises maintenance costs and gives our customers even more security.”