“The market wants to benefit not only from efficient machines, but also from the competence of the manufacturers,” says Jochen Pfeil, who has headed the Service division at Vecoplan AG since mid-June this year. Headquartered in Bad Marienberg in Germany’s Westerwald region, Vecoplan develops and manufactures machines and plants for the resource and recycling industry. “Our tasks include consulting, planning with subsequent solution finding, integrated order management, installation, commissioning – and of course comprehensive service,” emphasises Pfeil. “Customers want high levels of availability and process stability throughout the entire service life of the machines.”

Whether it’s plastics, used wood, scrap wood, waste, files or data storage media, the shredding, storage, separation and conveying solutions from the Westerwald company process different materials into high-quality output and feed them back into the raw material cycle. Vecoplan designs the plants and systems for continuous operation. To this end, the machine manufacturer offers users various service agreements that they can tailor to their operations and contractually define. This all starts with spare parts: “Components that are supposed to ensure the longest possible service life of the machine are naturally subject to wear and tear,” says Pfeil. Short delivery times and a high level of supply security are crucial. The company has invested several million euros in production modernisation, including the expansion of in-house production of replacement and wear parts, such as cutting tips. “This means we can offer a high vertical range of manufacture and comprehensive storage capacities. We can supply our customers quickly with wear parts – and produce custom parts with short delivery times if required.”

Experience and product knowledge

Vecoplan provides its customers with everything from a single source: installation, commissioning and service. During conversations with customers, Jochen Pfeil has often noticed that they attach great importance to well-trained specialist personnel. They expect comprehensive know-how in the usage scenario. “The more competent our employees are, the more our customers trust us. Users receive high quality from our service teams, even if the schedule is tight,” says Pfeil.

The demand for qualified specialists is constantly increasing with the rising number of installed systems. In recent years, Vecoplan has developed and brought machines to market in line with demand, enabling it to continually expand its product portfolio and provide its customers with comprehensive support, even in very difficult usage scenarios. “We hold training courses at regular intervals to make sure that all our service employees are on the same technical and administrative level, and we can use audits to ensure the quality of their work,” says Pfeil. “Our Technology Centre also gives us the opportunity to train our technicians extensively on the machines and on new machine developments. If required, we teach them how to find individual solutions based on the technical performance of the machines.”

“Germany and other European countries are largely served by our own service technicians,” says Pfeil. “We also have sites in the USA, the UK, Spain and Poland. Regions that we have not staffed with our own personnel are covered by our partner network.” This means that customers all over the world always have a direct contact person. This proximity enables the technicians to react faster – and shorter distances are of course also less costly for the user. Vecoplan is continuously expanding its European sales network.

Once the equipment and systems have been installed at the customer’s premises and are ready for operation, Jochen Pfeil and his team will train the customer’s personnel and check the equipment at regular intervals for compliance with accident prevention and occupational safety regulations. “We also offer a wide range of service tutorials that provide customers with professional support for the independent replacement of wear parts,” explains Pfeil.

Digitalisation is on the advance

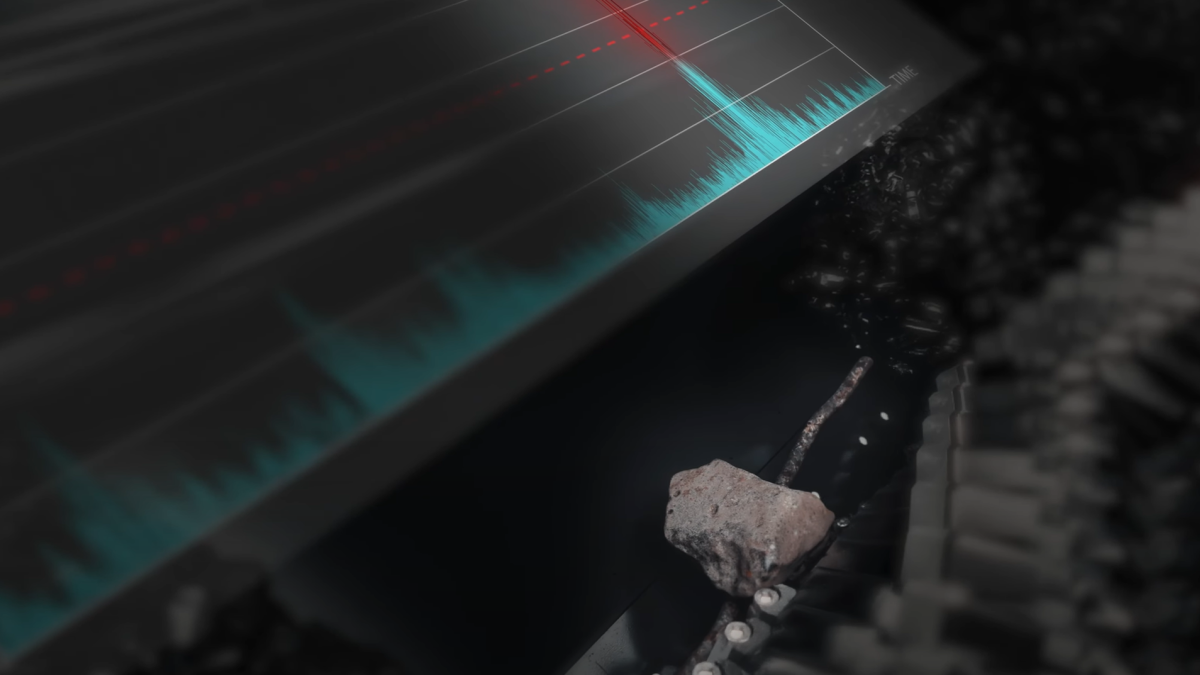

The latest customer demand in the service sector? It’s digital networking of machines with the manufacturer to allow remote access at any time. Vecoplan’s specialists can access the controller or the control panel and identify, analyse and eliminate errors in real time. Live images can be transmitted via webcams and complex technical issues can be explained using chat or video/teleconference technology. “Relevant data and documents are also available online,” says Pfeil. All the service measures are also listed. For example, users are reminded in good time when maintenance activities are due.

Vecoplan has bundled the implementation of these requirements in its Vecoplan Smart Center Strategy (VSC). The Westerwald company offers a modern communication interface via VSC.connect, for example. “The basic equipment includes the monitoring and evaluation of machine data and the issuing of service requests,” says Pfeil. The customer also has access to relevant documentation such as operating manuals, data sheets and tutorials. “Thanks to this powerful digitalisation concept, we can maximise the efficiency of our plants and systems,” explains Pfeil enthusiastically.

Users can activate many additional services, such as online commissioning, remote service, predictive maintenance and document management via an integrated app store. The intuitive VSC.control operating panel serves as a communication medium for the modern control system and as a link to the Vecoplan technicians. “Of course, our customers can also use it to operate the machines simply and intuitively,” emphasises Pfeil. This is a huge relief, especially if you have to process various materials that have different requirements. Vecoplan has integrated a settings manager to this end. Settings for different materials, which have proven themselves in practice, can be saved and called up at any time. “Customer satisfaction is our top priority and we are continually developing this business segment to achieve that,” promises Pfeil.

The integrated and intuitive VSC.control operating panel not only serves as a communication medium for the modern control system and as a link to the Vecoplan technicians, it also allows the machines to be operated easily and intuitively.

Jochen Pfeil: “The market wants to profit from efficient machines and from the competence of the manufacturers.”