At its Stand F66 in Hall 25 Vecoplan will give its first live trade-fair demonstration of the Vecoplan Pallet Crusher (VPC). Together with the VHZ wood shredder, it is an efficient means of shredding pallets and boxes in a continuous process. Until now, material centres, distribution centres and DIY stores have had to rely on large, powerful single-shaft shredders for continuous processing of large-volume wooden components. These machines took up a lot of floor space, in contrast to the combined solution consisting of the VHZ and VPC. They also had relatively low throughput, because the bulky load carriers fed to them contained lots of air. With the VPC, bulky parts are broken, not cut. After this pre-shredding they can be reduced even more in size, allowing the throughput to be increased by up to 50 percent as compared to single-shaft shredding. For customers this also means minimum wear. The combination is already very successful on the market.

At the trade fair the VPC will be connected via the cloud to the Vecoplan Smart Center (VSC). Vecoplan already demonstrated this at LIGNA 2019. In the meantime the company’s experts have added many more services to the VSC, including online commissioning, remote service, KPIs and access to a media database. How does this work? Visitors to the Vecoplan stand will find out.

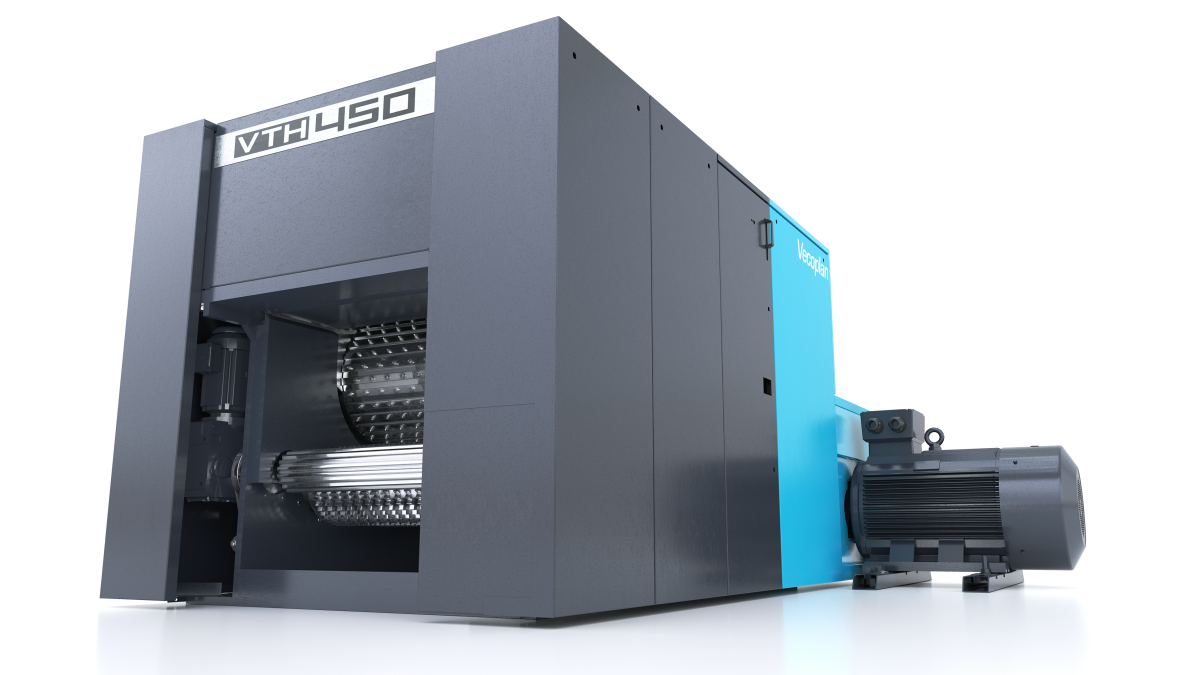

Chipper in a new design

Another trade fair highlight will be the relaunch of the VTH 450 biomass chipper, which is used in chipping plants in the energy & pellet industries, biomass heat & power plants and boiler feed systems. The VTH 450 is the first machine in Vecoplan’s line of biomass chippers to come out in a new industrial design. Here the company’s engineers paid particular attention to ergonomics and efficiency. The new design, which features closed side walls and an internal drive unit, also limits the escape of dirt. Cleaning requirements are significantly reduced. Another advantage is that important areas can easily be reached by service technicians in spite of the enclosed housing.

Visitors to LIGNA will also learn about the challenging waste shredding operations of the Finnish-Swedish company Stora Enso. The company needed an effective processing line for large quantities of solid production waste consisting of cross-laminated timber (CLT) from house construction. This wood material, which can serve as a substitute for concrete and steel, has become popular for use in ceilings, roofs, walls and stairs on account of its strength, appearance and versatility. Stora Enso can use the processed waste materials for power generation and heating.

Vecoplan will also be showing the first images of the prototype of its new VVB primary crusher. A user that produces fuels from biomass is currently putting this world-first solution through its paces. Vecoplan will present facts and figures on the VVB in Hanover.

Vecoplan at LIGNA: Hall 25, Stand F66