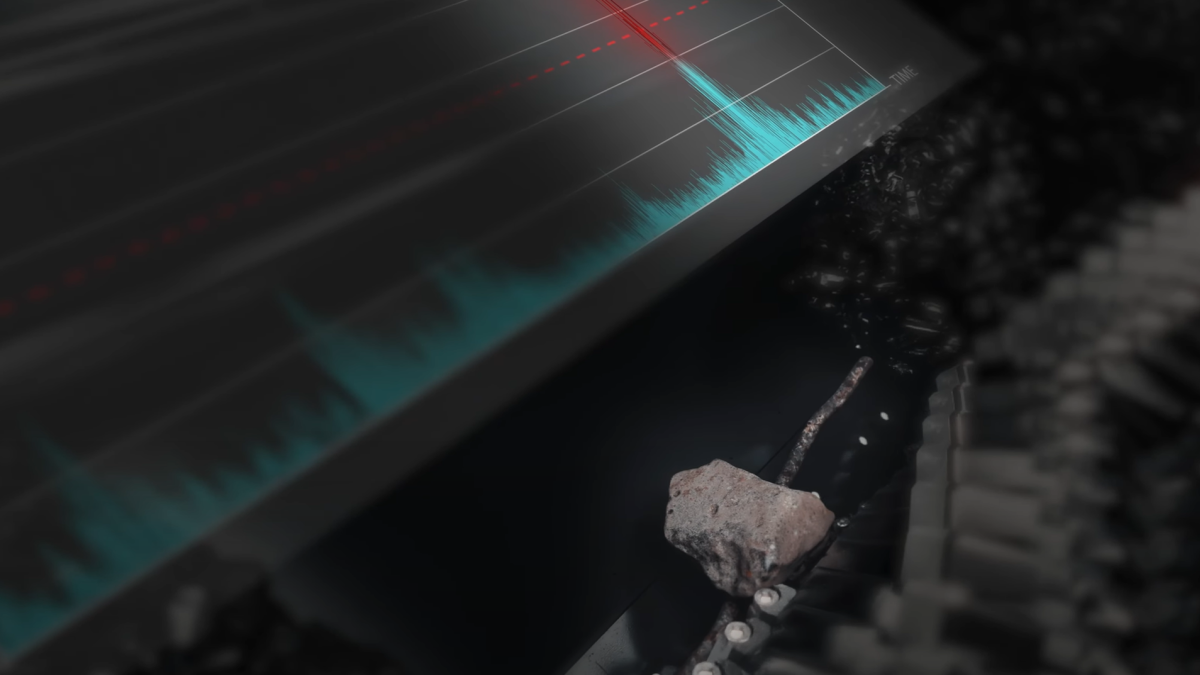

“Digitalisation, Industry 4.0 and the ability of our machines to make predictions based on data were the main factors that drove our decision to launch a new user interface for the control panel,” says Daniel Kessler, Head of Electrical Development at Vecoplan AG. The specialist company from Germany’s Westerwald develops, produces and sells machines and plants for shredding, conveying and processing primary and secondary raw materials in the production and materials cycle. The new operating concept supports the user by increasing the transparency and productivity of these solutions and making their operation more energy-efficient, with statistical data recorders, for example, and dashboards – it also records all the machine parameters, which can also be exported.

The new user interface can be used on all conventional mobile devices – and this is an interesting option, especially for managers and senior employees, because they can use their smartphones and tablets to remotely access all the machine information and settings adjustments at any time, without the need for them to be on site. The previous version did not have this capability. The Internet can also be accessed via the machine’s control panel – to order parts from the Vecoplan webshop, for instance. If a customer needed a certain component because it was worn out, he had to order it on his smartphone or PC. “We offer the operator the option of conveniently ordering the part directly from the machine,” says the Vecoplan specialist.

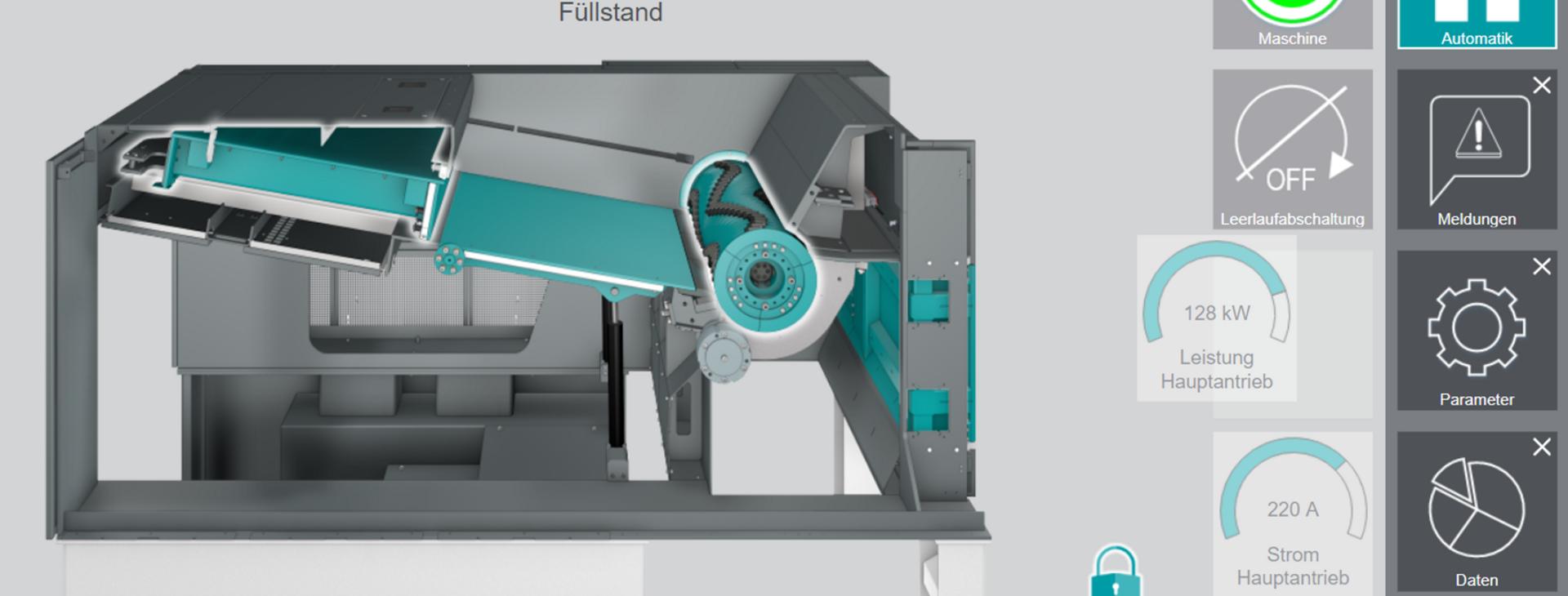

The developers attached great importance to user friendliness. “A positive user experience (UX) was a must for us. That’s why we have given our panel a modern UX design, making the operation of the human-machine interface as comfortable and pleasant as possible for the operator,” says Daniel Kessler. Compared to the previous version, the handling is even easier and more intuitive for users. The employee benefits from various aids, such as the digital provision of service videos and machine documentation with self-explanatory pictograms and simplified images. The control elements can also be personalised and saved to match the needs of every individual operator. In terms of colour, the surface is integrated into the Vecoplan Corporate Design. “Of course, we asked several people about their requirements in advance,” Daniel Kessler said. “Because of their different technical backgrounds, age and deployments they have different ways of working with control panels. The new control panel is based on these findings.”

Daniel Kessler, Head of Electrical Development: “We’ve now made the operation of this human-machine interface as convenient and as pleasant as possible for the operator.”

Vecoplan has designed the new control panel in such a way that all the work processes at the shredders can be handled intuitively by the employees, who can also go online via the control panel.