Energy crises and the associated volatility of electricity prices have noticeably changed the framework conditions for recycling. For many companies, this means that resource consumption, cost structures, and energy efficiency must be optimized more consistently than before in order to remain economically viable.

At the same time, pressure on companies is increasing from two sides. Ever-rising quality standards are putting more pressure on operators of recycling plants, sorting centers, and production facilities with their own waste streams.

At the same time, the complexity of recycling processes continues to increase:

- Input materials are becoming more heterogeneous.

- Processes are becoming more variable.

- Documentation requirements are becoming more extensive.

Technological innovations in the form of digital control platforms are becoming a fundamental component of modern recycling technology and are crucial for the future viability of individual companies.

What innovative approaches are there in processing technology?

One thing is clear: these challenges can hardly be solved economically with classic machine technology alone. What is needed are intelligent, networked systems that combine mechanics, control technology, and digital services.

This was therefore the guiding principle for Vecoplan AG last year. For us, innovation means:

- less downtime for plants,

- longer service life for individual machine components and less wear and tear,

- the option of retrofitting existing plants with smart tools

to ensure more economical operation of your plant.

Why is investing in innovative solutions important right now?

In economically challenging times, it is understandable to want to put investments on hold. However, plant operators should also bear in mind that investing in innovation during difficult times can create opportunities – for example, through lower unit costs and fewer unplanned downtimes. Innovations become a stabilizing factor and help to build a competitive advantage in day-to-day operations.

This can be seen very clearly in practice: crushers, conveyor lines, screening and cleaning stages can be networked via digital controls, monitored with sensors, and optimized using automated functions (e.g., foreign object detection).

Smart technology in the shredding process for retrofitting

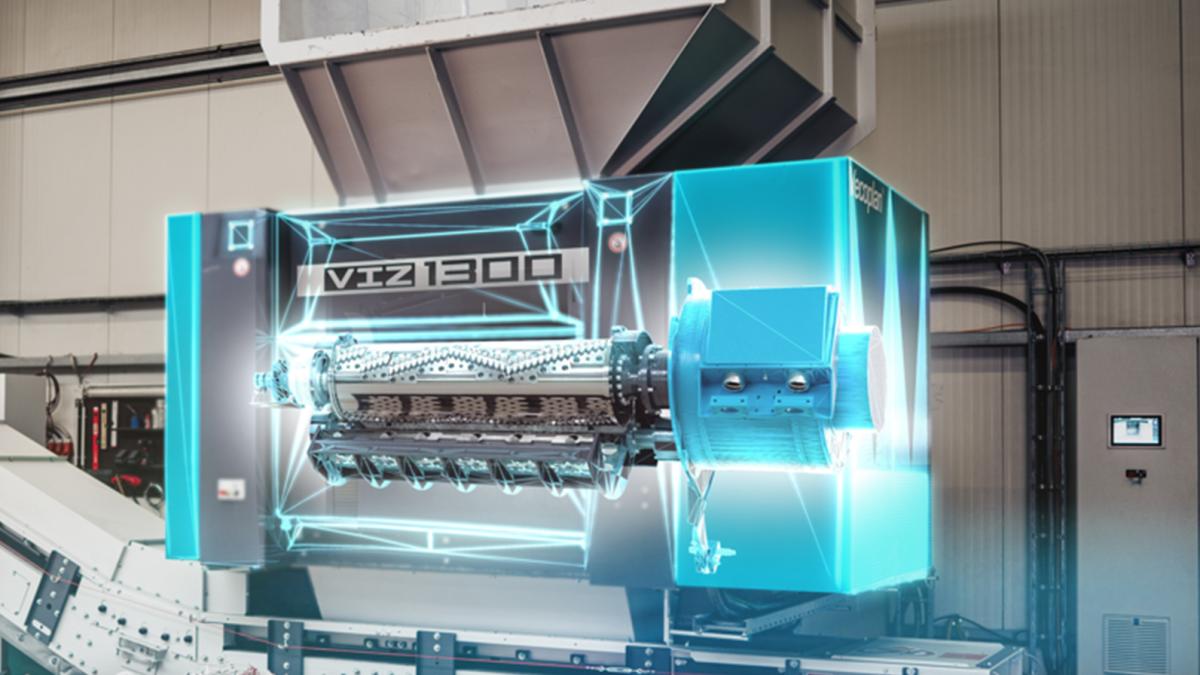

Innovative waste treatment plants, digital control platforms, and automated monitoring and response systems are no longer prototypes, but have proven themselves in a wide variety of practical applications. Applications with VAZ-, VEZ- und VIZ series show how modular, scalable solutions with adaptive machine controls, real-time data, and automated maintenance offer consistently high performance and process reliability in real time.

The Vecoplan Smart Center (VSC)

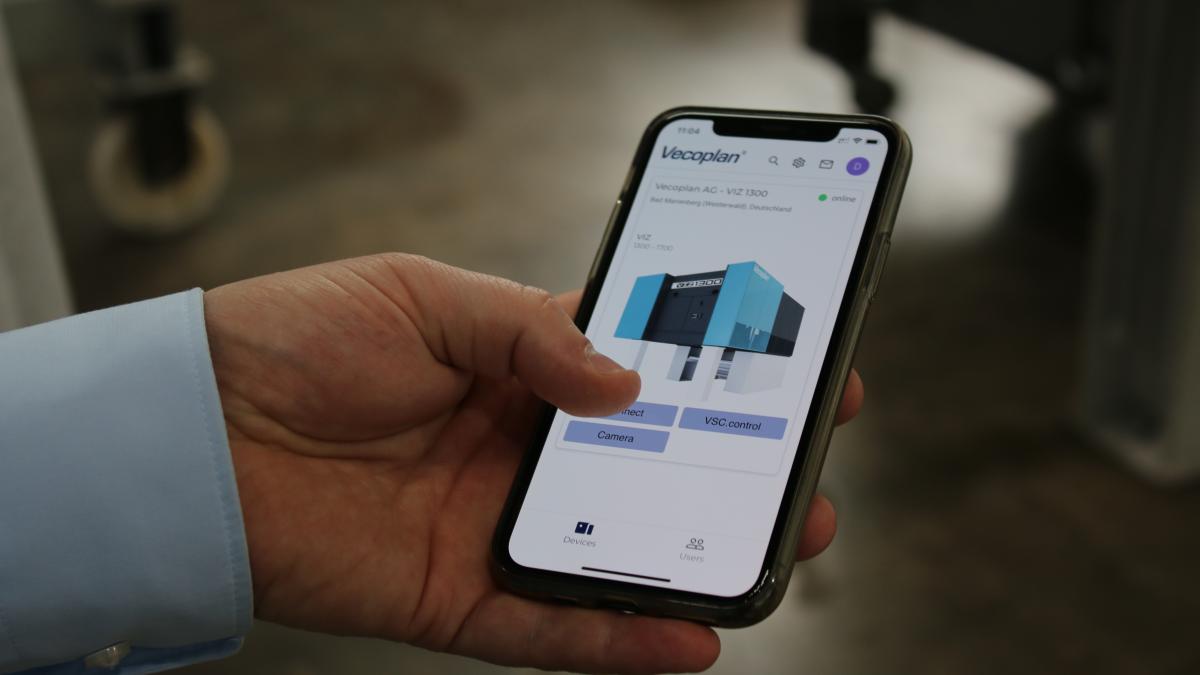

Vecoplan Smart Center (VSC): The digital control platform for process optimization and efficiency.

This system is at the heart of modern processing technology and serves as a cloud-based digital control platform for machine monitoring, data analysis, and process optimization.

The VSC collects all relevant real-time data—from performance values to shift and batch statistics to CO₂ equivalents with a resolution of 100 milliseconds. KPI dashboards allow users to analyze consumption values, load factors, and emissions in a targeted manner and link them to operating parameters.

The integration of the VSC also makes it possible to

- commission systems remotely

- perform remote service (remote access by Vecoplan to the system in order to quickly diagnose and rectify problems)

- and manage support cases digitally and efficiently

Thanks to secure cloud connectivity and standardized interfaces, the system integrates seamlessly into your existing IT environments. Automated push and call notifications immediately report deviations, anomalies, and malfunctions—enabling operators to intervene proactively and minimize downtime.

Intelligent Interference Detection (VID)

Foreign objects in the shredding process are one of the most common causes of damage and unplanned downtime. Metals, glass, ceramics, or press wires can cause massive damage to knives, rotors, and bearings. The Vecoplan Intelligent Detect (VID) module monitors your shredders in real time using intelligent vibration sensors and detects foreign objects and anomalies directly in the shredding process.

At the same time, the use of VID leads to measurable quality stability in the output. Fewer foreign materials and optimized processes significantly reduce energy consumption and machine wear (e.g., fewer filter changes). Existing systems can be easily retrofitted with VID, which both increases investment security and promotes sustainable operation.

A key feature of VID is its adaptive mode of operation:

- When a new batch of material is added, the system first analyzes the vibration behavior.

- Based on this data, VID independently sets material-specific threshold values.

- These “recipes” can be saved and reloaded at the touch of a button.

The future of recycling technology: Focus on development, networking, and customer success

Industry trends point in a clear direction:

- Increasing automation

- Seamless digitalization

- And greater networking of all plant components

are becoming standard. This is an advantage for operators with existing Vecoplan technology: Innovations can be easily retrofitted.

With the increasing integration of VSC and VID into existing and new systems, the degree of automation is rising throughout the entire processing process—from material reception to shredding and sorting to material recycling. Customers benefit in the long term from greater predictability and transparency regarding current costs, resource consumption, and emissions.

Vecoplan as a long-term development and technology partner

In this environment, we see ourselves as a long-term partner, not only in the planning of a new plant, but throughout its entire life cycle. This includes:

- Joint development of tailor-made solutions.

- Continuous further development of hardware and software.

- Support with digitalization, data analysis, and process optimization.

The focus remains clear: making customer processes safer, more efficient, and smarter.