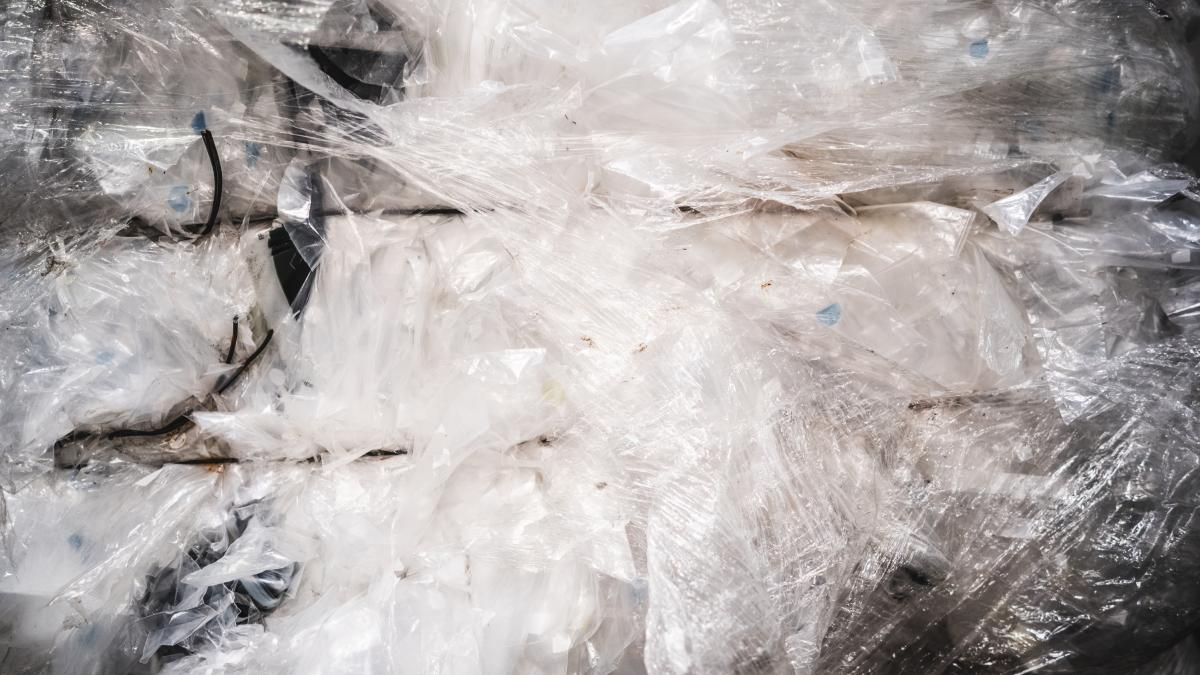

The new Vecoplan V-ECO 1300 shredder is still enclosed in scaffolding. “However, we will soon replace it with a steel structure for operation of the feed roller,” says Holger Trumpfheller, head of maintenance at KW Agri GmbH & Co. KG in Michelstadt, Germany. At the top, near the hopper where the material is fed into the shredding chamber, one can sense the enormous force applied by the machine as it transforms waste plastic into homogeneous output material. “We’re going to use the new system to shred all of our film waste and then use it for production,” says Trumpfheller. This will include production waste from the site, film waste from other locations of the RKW Group and material purchased from other plastics manufacturers. Most of this is film derived from rolls and bales.

The independent family-owned RKW Group is one of the world’s leading manufacturers of high-quality film solutions. It is the foremost maker of film for use in hygiene, agriculture, beverages and packaging of powdery goods. It also supplies film and non-woven materials for medical applications, the chemicals industry, the manufacturing sector and construction.

In fiscal 2018, RKW had total revenues of 878 million euros. Each year, its approximately 3,000 employees process 367,000 metric tons of plastic at the company’s 20 locations worldwide.

Optimising the recycling process

Recycling of production waste is an economically attractive solution for companies. Scrap can be processed into regrind and returned to the production cycle, where it has almost the same quality as new material. In this way disposable waste does not arise in the first place and a closed cycle is created. “Using our own regrind helps us to achieve our sustainability goals,” explains Silke Helmstädter, lead buyer for regenerated material at RKW. “As a privately owned company we care about future generations.” The company is committed to preserving a liveable environment. Sustainability is thus an integral part of its corporate policy and business mission. For RKW, protecting resources means reducing emissions, minimising waste through recycling, avoiding harm to the environment and streamlining logistics.

In keeping with these sustainability goals, RKW Agri in Michelstadt launched a project to optimise its recycling department. The aim was to generate homogeneous shredded waste, improve its internal processes, cut costs and make regeneration significantly more productive. For this purpose the project’s decision makers turned to Vecoplan AG. Headquartered in Bad Marienberg in Germany’s Westerwald region, Vecoplan develops and manufactures machines and plants for the resource and recycling industry. “Our tasks include consultancy, planning and finding solutions. We provide integrated project management, including installation, commissioning and comprehensive service,” explains Cathrine Rekett, head of application technology in Vecoplan’s Recycling and Waste Division. “For RKW we provided all of the mechanical processing equipment upstream of the extruders. We did the planning, programmed the major components according to a fully automatic control plan, carried out the installation and commissioned the plant.”

On the factory floor a worker picks up a bale of film from a pallet with a stacker truck and drives it to a chain belt conveyor. An associate uses pliers to take off the wires holding the bale together. The material gradually falls onto the belt, which moves it steadily upward towards the feed channel. “The V-ECO is so strong that it could even process the wires safely,” says Cathrine Rekett. “But there is less wear on the cutting tools when the wires are removed, and as a result the particles are more homogeneous, with a smaller fraction of fines. Moreover, the throughput is better.” At the top, a feed roller at the hopper pulls the wound-on film from the roll into the shredding chamber.

Flexible and energy-efficient operation

“After thorough deliberation, we opted for Vecoplan and the V-ECO,” says Trumpfheller, RKW’s head of maintenance. “We were highly convinced by the design of this shredder.” The machine is flexible and focuses on energy-efficient operation. It even shreds extremely difficult materials with high-quality results and at a high throughput. The decisive advantage is its cutting geometry. “We can exactly adapt our plants to input and output requirements by changing the rotors and blades and selecting the right screen,” says Cathrine Rekett. Through numerous tests at its in-house technical centre, Vecoplan’s application engineers fine-tuned these components for use at RKW. At all times they were in touch with the customer in order to determine the requirements for the optimum particle size in the downstream process. The experts selected rotor diameters, cutting geometries, screens and cutting tools to correspond to the mechanical properties, thermal properties and dimensions of the input material and the output requirements.

Easy to maintain, repair and operate

Vecoplan emphasises a consistently compact machine design. This reduction down to the essentials minimises susceptibility to failure, optimises the material flow and makes all service and maintenance work easier for users. The hydraulically swivelling bottom flap and the downward-swivelling screen allow easy access to the rotor for operators, who can immediately remove extraneous material, exchange the counter knife or adjust it from the outside. Material feed to the rotor is continuous thanks to the inclined design of the machine floor and the continuously adjustable ram control. This ensures that the process is uninterrupted.

For energy-efficient operation Vecoplan installed the cost-effective ESC drive (Electronic Slip Control). “This solution makes gears and turbo clutches superfluous,” says Rekett. The multi-pole, asynchronous drive motor with its powerful frequency converter works together with a special belt drive that incorporates a sophisticated slip control and an extraneous material detection system with a motor or rotor brake. Together with the proven start-up and reversing controller from the HiTorc drive, 2 to 2.5 times torque can be achieved for a short time with this combination.

Bridging maintenance times

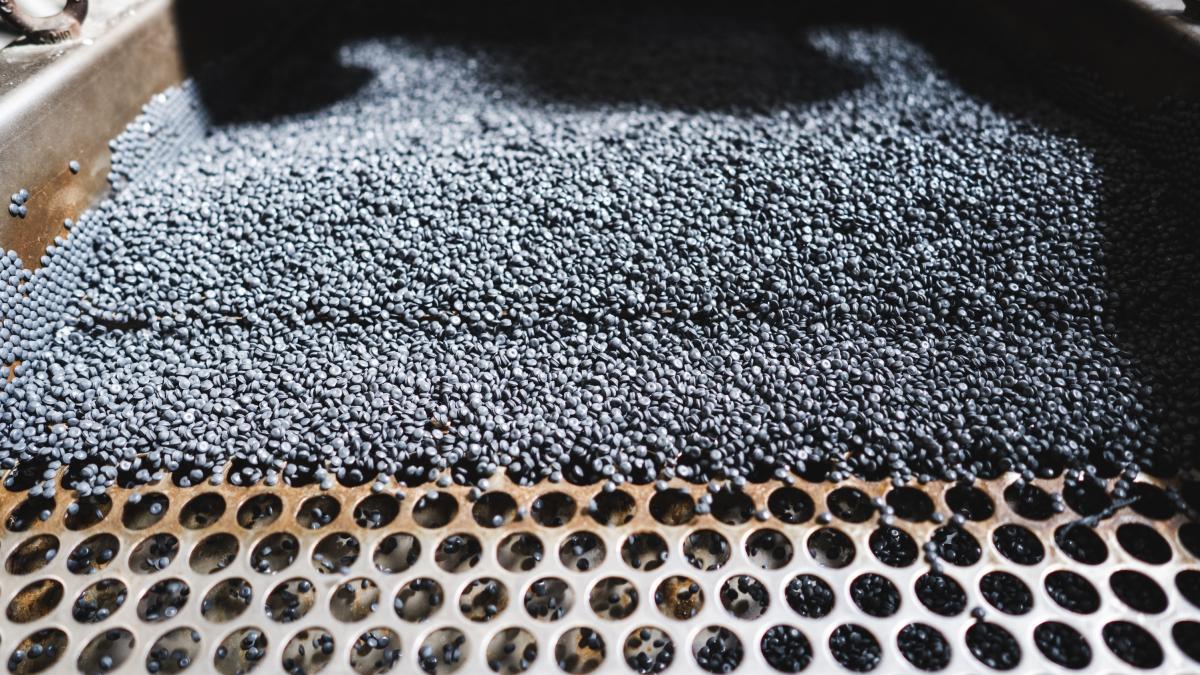

A worm conveyor transports the output material from the machine to a drag chain conveyor, which moves it up to the next floor. Here Vecoplan has installed a magnetic separator for removal of ferrous materials. Following this, all non-ferrous metals are removed. Conveyers then take the film flakes to a film silo. “We put this material into temporary storage because the throughput of our shredder is higher than that of the two extruders,” says Rekett. “In this way the customer can bridge waiting times which can arise when an employee has to replace cutting tips or remove extraneous material. The extruders continue to run.”

Standstill? No problem

What happens if the system in Michelstadt suddenly shuts down? In such cases the customer can reach Vecoplan via the service hotline around the clock, every day of the year. Help comes over the phone right away. Vecoplan’s technicians first try to rectify the problem via remote diagnostics. In many cases the systems can go back online very quickly. In addition, the causes of the malfunction are determined in order to prevent a recurrence. RKW additionally signed up for an economical and efficient feature, Vecoplan’s Live Service. Users can request direct online support from Vecoplan’s service technicians, who can access the controller and the control panel and identify, analyse and eliminate errors in real time. Live images can be transmitted via web cams and complex technical issues can be explained using chat, video or teleconference technology. In addition, relevant data and documents can be called up online. All the service measures are also listed in the Maintenance Manager.

Meeting the challenge

“Installing a system like this on two floors was no ordinary achievement,” says Cathrine Rekett. “It was a considerable challenge for our installation team.” That is because the factory building was already there and could not be changed. One difficulty was getting individual pieces of equipment up to the second floor. What could be assembled right away, and what had to be brought up in separate parts? The roof was opened and the units were lifted up to the second floor by means of a crane. Thanks to good advance planning, the system was installed in seven days, after which it was commissioned. The responsible employees were then given instruction. “We explained all the important functions and demonstrated jobs like correct adjustment of the counter knives and replacement of the cutting tips,” says Rekett.

The V-ECO 1300 has been in operation since August 2019. “This highly efficient shredding system is not only saving us lots of money,” says the project team at RKW Michelstadt. “We’ve also increased the quality of the output material, optimised our internal processes and boosted our productivity.” And advantages like these are becoming increasingly important, because customers’ expectations for various kinds of film are growing day by day.

Exemplary in-house film recycling

RKW Agri GmbH & Co. KG processes film waste from its own production and from various production sites of the RKW Group in Michelstadt and feeds it back into the process cycle. Vecoplan supplies a complete system around two existing extruders.