Flexible shredding tools for all wood-based materials

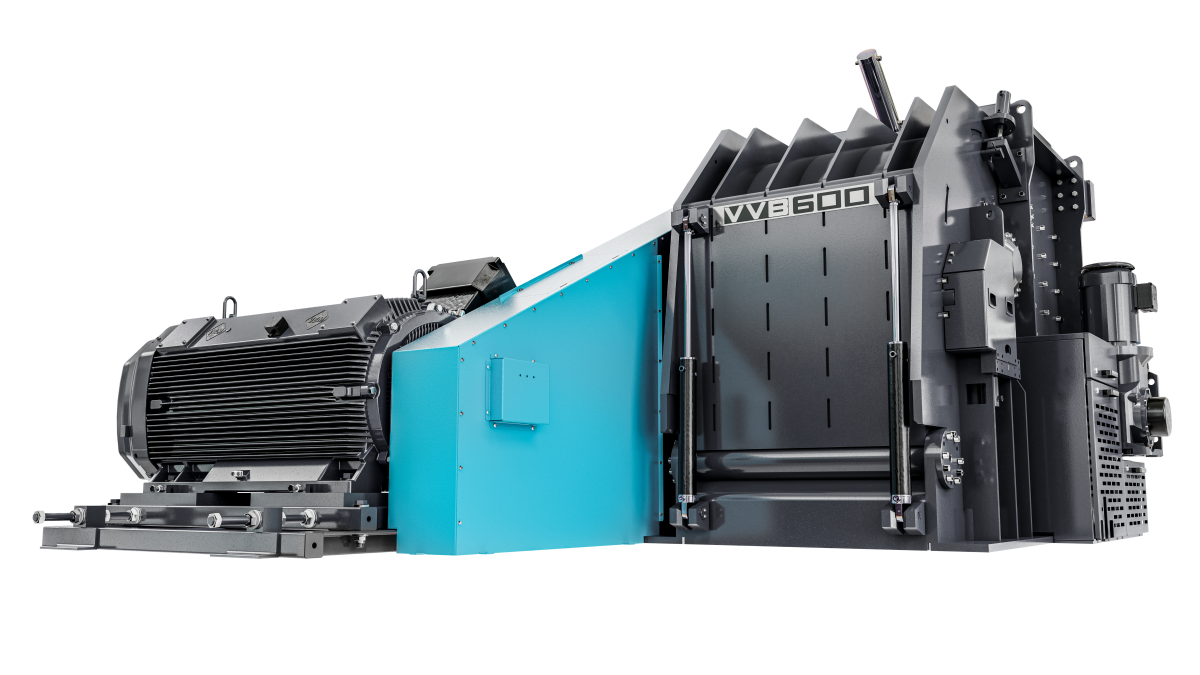

This primary crusher breaks all wood materials such as fresh bark with up to 60 percent water content, logs up to 400 millimetres in diameter, and pile caps up to 1,000 millimetres in diameter. It also can process roots, stumps, log yard residues, sawdust, short waste wood, pre-crushed pallets and demolition wood.

The shredding tools are arranged in an M-shape on the rotor, ensuring quiet running. Despite the large flywheel mass, rotor standstill is achieved in less than five minutes. Depending on the configuration, the machine can produce fuel in particle sizes from P45 to P100, compliant with DIN EN ISO 17225.

The experts will tailor the machine to the customer’s application if necessary. For example, different tools are possible depending on the application. These tools can be used on both sides and can be partially changed, reducing costs for the operator. Vecoplan designed the primary crusher with a pivoting counter knife and screen unit secured by shear bolts so that up to two percent of impurities cannot harm it. Once the impurities have been removed, the counter knife and screen unit return to their operating position.

Comfortable and save maintenance

The machine is equipped with a casing to minimise dust leakage during crushing. The technician can dismantle the casing in just a few simple steps before carrying out service work. A downward-opening hood allows quick access to the rotor. A maintenance platform is also integrated into the hood, making service work convenient and safe. An angle encoder ensures optimum lifting, lowering and damping of the upper infeed roll, adapted to the input material. The drive of the upper infeed roller is internal. The drive’s lubrication and temperature monitoring are done automatically.

User-friendly digitalisation

With the VSC.connect Vecoplan offers a modern communication interface to the customer’s plant. So, also the VVB primary crusher can be connected to the Vecoplan Smart Center (VSC), which can be used on all common mobile devices. Users can access online commissioning, remote service, key performance indicators and a media database. The modern VSC.control operating panel is a communication medium for controlling the VVB. Machine parameters and the storage of the settings can be intuitiv adapted by the operater. So he receive an overview of individual actual values and current messages, including a message history.

Your challenge

Sawmill operators often have the problem that the pre-shredding of input materials with a high moisture content does not take place with a sufficiently high throughput. Roots, stumps, residues from the log yard, sawdust and short wood waste as well as pre-broken pallets and demolition wood mean that the subsequent processes cannot be continuously fed with the possible material throughput. The VVB, on the other hand, is designed for high throughput with demanding material.

Your benefits at a glance

- A robust design combined with enormous flywheel mass

- Very high throughput rates

- No metal detector required for extraneous content below 2%

- Maximum reliability and availability

- Optimised for ergonomic maintenance and service

Get non-binding advice

Vecoplan offers complete systems that can cover all your applications, from shredding, conveying and storage to separation.

Feel free to contact us regarding your individual challenges. Whether it is for high-throughput processing in biomass cogeneration plants or in the energy and pellet industry. Contact us here.