Wood shredder (VHZ)

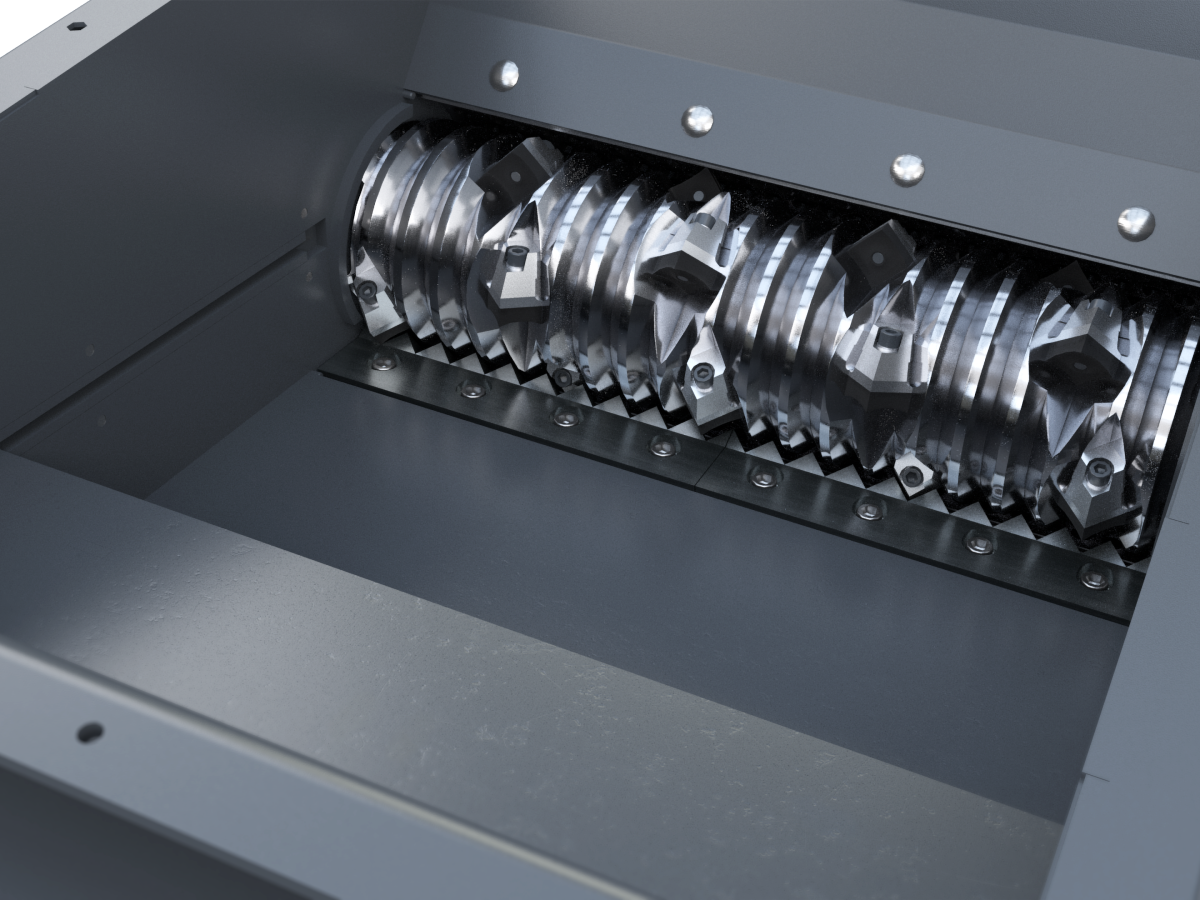

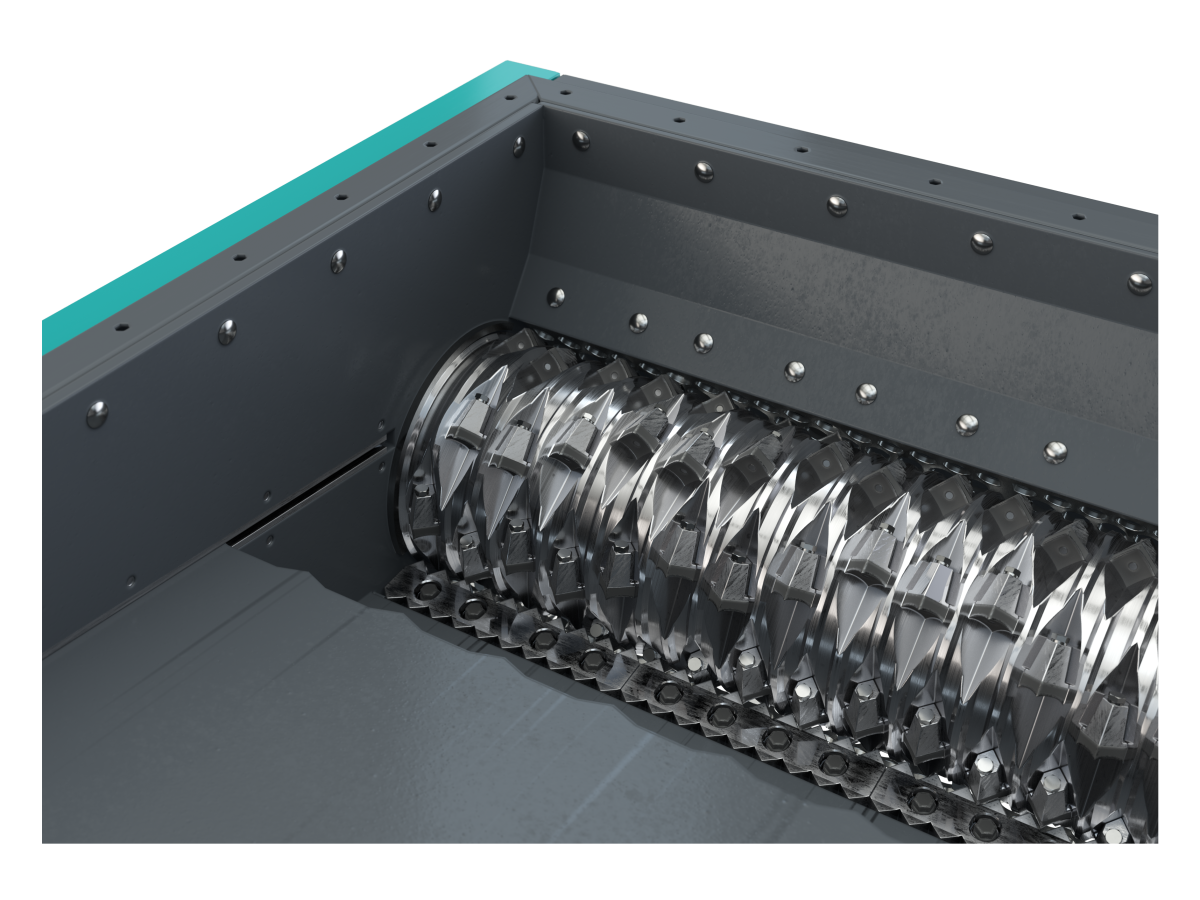

Energy-efficient shredder for a wide variety of wood wasteDo you want to reliably process chipboard, hardwood and solid wood waste, bark, softwood and even whole pallets into wood chips and briquette-ready material? Our VHZ series of compact and robust single-shaft shredders has been specifically designed to master these tasks. You’ll benefit from low operating costs thanks to energy-efficient drive technology, and in most usage scenarios, you can feed the collected materials directly to the machine without the need for additional feeding systems. Since the rotor turns particularly slowly, it makes little noise or dust during vertical feeding.

Discover the VHZ wood shredders from Vecoplan

Flexible wood-allrounder - the solution for the wood processing industry and small businesses

Our VHZ wood shredders are durable and robust shredding solutions specially developed for the needs of the wood processing industry as well as for carpenters, joiners and woodworkers. The reliable single-shaft shredders are the economical option for feeding a wide variety of input materials and different feed quantities directly and in an undosed manner into the shredding process.

The highlights of the new VHZ wood shredders

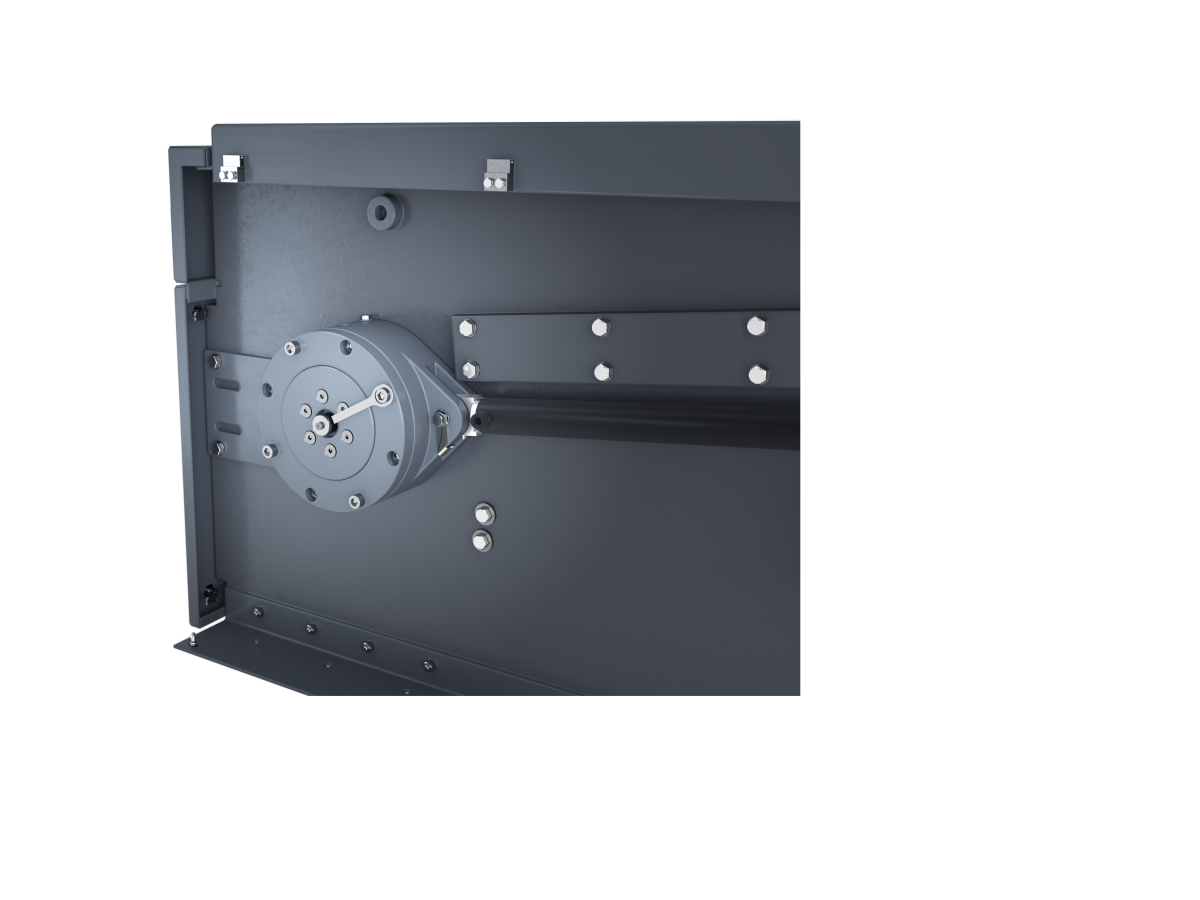

ESC-Drive - an investment that pays off

The ESC-Drive with patented belt technology is an extremely energy-efficient and economical solution for drive powers from 45 to 90 kW. Here, an asynchronous motor with a powerful frequency converter works together with a high-performance belt drive with sophisticated slip control and a tramp material protection.

Your advantages at a glance

- Energy savings of up to 25%

- Tramp material detection

- Highest throughput

- Low maintenance costs

- Simple and fast maintenance

The energy-efficient wood shredders form Vecoplan

The small VHZ series is a durable and robust solution for shredding wood waste and residual wood - specially developed for the needs of the wood working industry as well as for carpenters, joiners and woodworkers.

Which model suits your needs?

| Specification |

|

|

|

|

|

|

|---|---|---|---|---|---|---|

| Type of drive | Belt drive ESC | Belt drive ESC | Belt drive ESC | Belt drive ESC | Belt drive ESC | Belt drive ESC |

| Motor power | 18,5 kW | 18.5 - 22 kW | 30 - 37 kW | 45 - 90 kW | 37 - 45 kW | 45 - 90 kW |

| Speed range | 90-250 1/min | 90-250 1/min | 95-265 1/min | 105-295 1/min | 95 - 265 1/min | 105-295 1/min |

| Rotor length | 795 mm | 1,070 mm | 1,070 mm | 1,260 mm | 1,260 mm | 1,595 mm |

| Rotor diameter | 250 mm | 250 mm | 370 mm | 430 mm | 370 mm | 430 mm |

| Weight | 1.6 to | 1.85 to | 3.1 to | 5.8 to | 3.4 to | 7.2 to |

| Dimension (Length) | 2,340 mm | 2,340 mm | 2660 mm | 3,360 mm | 2,660 mm | 3,360 mm |

| Dimension (Width) | 1,400 mm | 1,675 mm | 1745 mm | 1,915 mm | 1,940 mm | 2,250 mm |

| Dimension (Height) | 980 mm | 980 mm | 1150 mm | 1,580 mm | 1,150 mm | 1,580 mm |