Requirements

For the optimal recycling of film, the customer RKW needed an efficient processing plant. Because of the limited space available due to the unchangeable position of the two existing extruders, variable handling of the input material in a very confined space must be ensured, as well as different feeding methods.

Solution

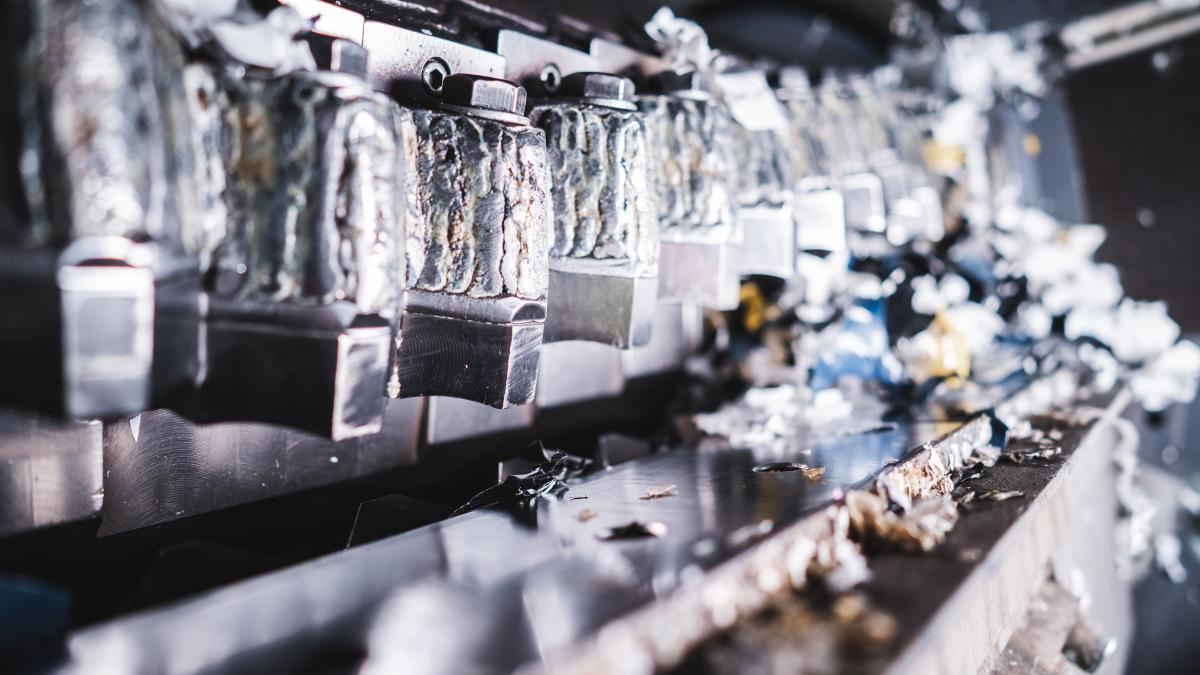

The plant is set up on two levels. The feeding and shredding takes place at ground level, while separation and storage take place on the upper floor. For this purpose, Vecoplan supplied a V-ECO 1300 as well as the corresponding conveying, storage and dosing technology.

Result

Thanks to careful planning, the solution concept could be integrated into the existing plant in a very confined space without any problems. With this very efficient shredding technology, the customer not only saves costs, but also benefits from the increase in output quality.

Exemplary in-house film recycling

RKW Agri GmbH & Co. KG processes film waste from its own production and from various production sites of the RKW Group in Michelstadt and feeds it back into the process cycle. Vecoplan supplies a complete system around two existing extruders.

This highly efficient shredding technology not only enables us to make significant cost savings. We have also improved the quality of the output material, optimised internal work processes and increased productivity.