Scheduled to go into operation in the summer of 2020, the new plant will produce around 68 million litres of diesel and petroleum fuel, plus just under 23 million litres of wax every year – all won from around 100,000 tons of mixed plastic waste. The input consists of inferior materials, such as residual waste from recovery plants and production waste. Brightmark has commissioned the Vecoplan AG to supply the appropriate shredding technology to process this enormous quantity of plastics efficiently.

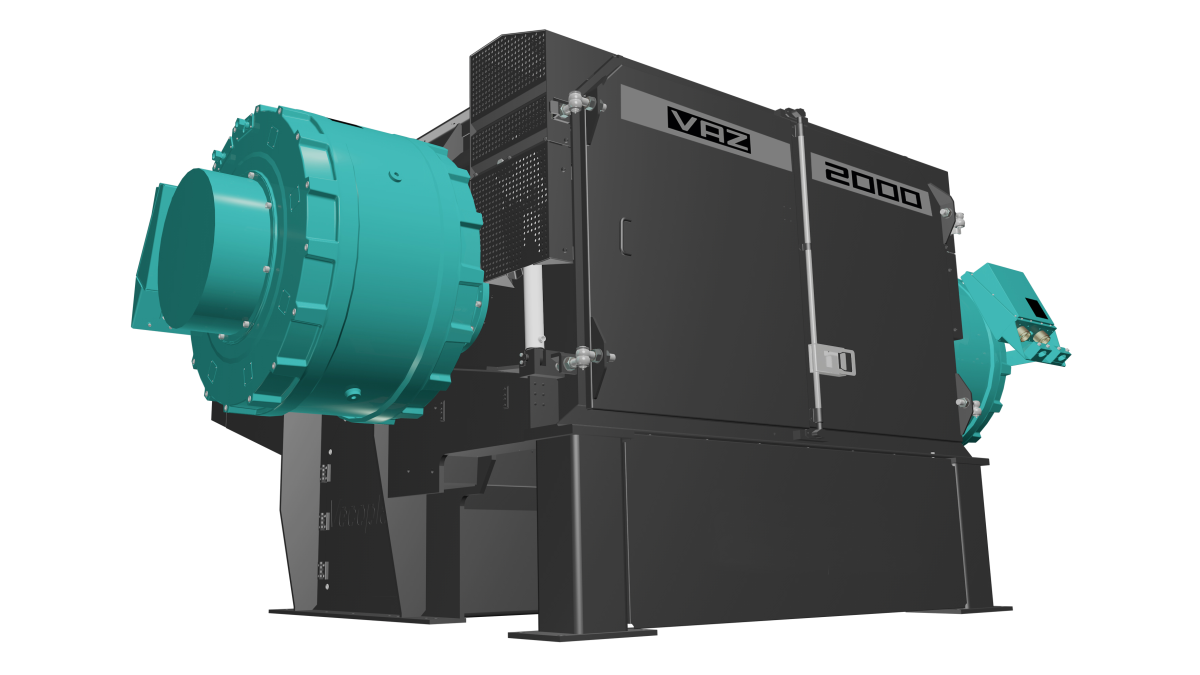

The Vecoplan Group, based in Bad Marienberg in the Westerwald region of Germany, will supply the VAZ 2000 single-shaft pre-shredder, as well as a VEZ 2500 high-performance shredder, which is regarded as a benchmark in the industry thanks to its consistently high throughput and the homogeneous quality of its output. Other system components are also necessary for plant operation – machines to remove non-shreddable foreign matter from the mass, for example, and to dry or pelletise the material. “In the run-up to the project, we carefully analysed the mixed waste to meet the plant’s stringent requirements,” says Bob Gilmore, the Managing Director of Vecoplan’s American branch in Archdale, North Carolina, which will carry out the project in Ashley.

Jay Schabel, Head of the Plastics Division at Brightmark Energy, is pleased that Vecoplan got the contract. “We checked out the relevant suppliers on the market really intensively – and it was Vecoplan who convinced us. We’re confident that we’ve selected the best supplier for this task.” He is also very enthusiastic about Vecoplan’s comprehensive service: “Now we’re looking forward to the successful installation of the systems,” he says. The ground-breaking ceremony will take place at the end of May.