Do you need to effectively and irreversibly destroy sensitive documents or storage media like hard disks? This is not easy, and in recent years it has become even more difficult because the requirements have risen. What’s more, storage media are now smaller and their capacity has increased. Marco Thiel, a managing partner of sicher-vernichtet.de, a company specialising in mobile data destruction, explains: “The biggest problem is to achieve the required particle sizes while maintaining a high throughput.” One point of reference for his customers is the DIN 66399 standard, which specifies a protection class and a security level depending on the type of medium and the kind of information stored. These factors determine the particle size required for destruction. Other requirements are set out in the General Data Protection Regulation (GDPR) and the recommendations of the Federal Office for Information Security (BSI). sicher-vernichtet.de specialises in extremely small particle sizes and compliance with stringent security requirements.

Proven solutions

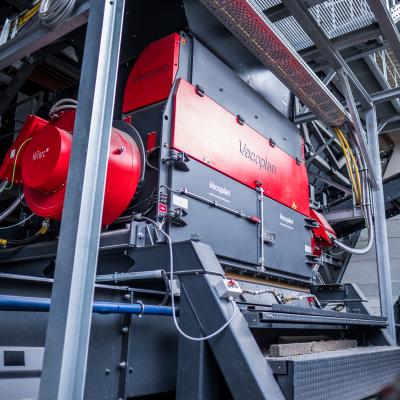

The company was founded in 2016, but Thiel has been in the business for more than 20 years. “During this time, I’ve come to know a number of shredder manufacturers,” he says. “For destroying data and documents, either double-shaft or single-shaft shredders can be used.” Thiel is well acquainted with both solutions. He is particularly impressed by Vecoplan’s single-shaft machines, which are suitable for a wide range of applications. Their patented rotor cutting units can process almost any material. No additional feeding systems are needed. The collected input can be placed directly in the machines without dosing.

For mechanical destruction of sensitive data, sicher-vernichtet.de relies on shredders from the VDS 800 series. These machines efficiently shred hard disks and other magnetic or optical data carriers such as tapes or CDs. “Using different screen sizes, we can achieve the particle sizes required by our customers for their respective security levels,” says Thiel. “Screens can be changed in less than five minutes.” The shredders can be fed with batches of up to 30 kilograms, and they operate very quietly thanks to their encapsulated design. For documents sicher-vernichtet.de uses compact VAZ 800 shredders. These durable and robust single-shaft shredders reliably produce an extremely homogeneous output. A hydraulically powered ram pushes the paper quickly and easily into the shredding mechanism.

Employees of sicher-vernichtet.de drive special vehicles with permanently mounted shredders to customers throughout Germany and do their work right on site. The dispatchers plan these trips so that as many customers as possible can be served within a short time. “The requirements can differ widely,” says Thiel. The machines operate for up to eight hours per day, five days a week. “This means they have to be very robust,” he explains. But machine reliability is only one factor. Thiel also counts on having a reliable partner. If a fault occurs, he knows that a service technician will help him to find and rectify it quickly.

What happens to the shredded material? Recyclable fractions, such as hard disks and PC boards, are returned to the materials cycle by partner companies. Shredded plastics are usually recycled as fuel.

sicher-vernichtet.de put its sixth machine, a mobile document shredder, into operation in October. We replaced the company’s first machine with a new one, and the other four have been in continuous operation for years.