The so-called refuse-derived fuels (RDF) or secondary fuels are obtained from non-recyclable waste from households, industry and commerce. According to EU directives, the production of these fuels is therefore not part of recycling. However, RDFs have become indispensable in the cement industry.

The energy input is now over 70 %. The energy recovery of waste through the production of substitute fuels therefore remains an important factor in waste treatment. Vecoplan's technologies for processing and handling can make an important contribution here.

How Vecoplan technologies contribute to energy recovery through waste processing

1. Shredding technology

Reliable and flexible shredding technology, high availability for maximum throughput and low operating costs are already on the wish list of most plant operators. In this context, the topic of energy efficiency is becoming increasingly important for replacement and new purchases. After all, a modern drive concept such as the HiTorc from Vecoplan can save up to 60 % energy compared to hydraulic drives.

Phenomenal technic - high-performance shredder

At IFAT in Munich, we will be presenting our VEZ 3200 RDF shredder, a prime example of efficiency and reliability in waste processing and RDF production, at our stand 229/328 in hall B5. The VEZ 3200 has already been successfully installed at a large number of customers.

Your advantages at a glance:

- Robust and durable design for extreme conditions

- Unlimited flexibility thanks to various configuration options

- Maximum reliability and availability

- Cost minimization through energy efficiency

- Ergonomic machine design for optimum maintenance and service accessibility

- Best added value thanks to consistently high and homogeneous output

- Intuitive machine operation via VSC.Control

- Online support and optimization via the Vecoplan Smart Center

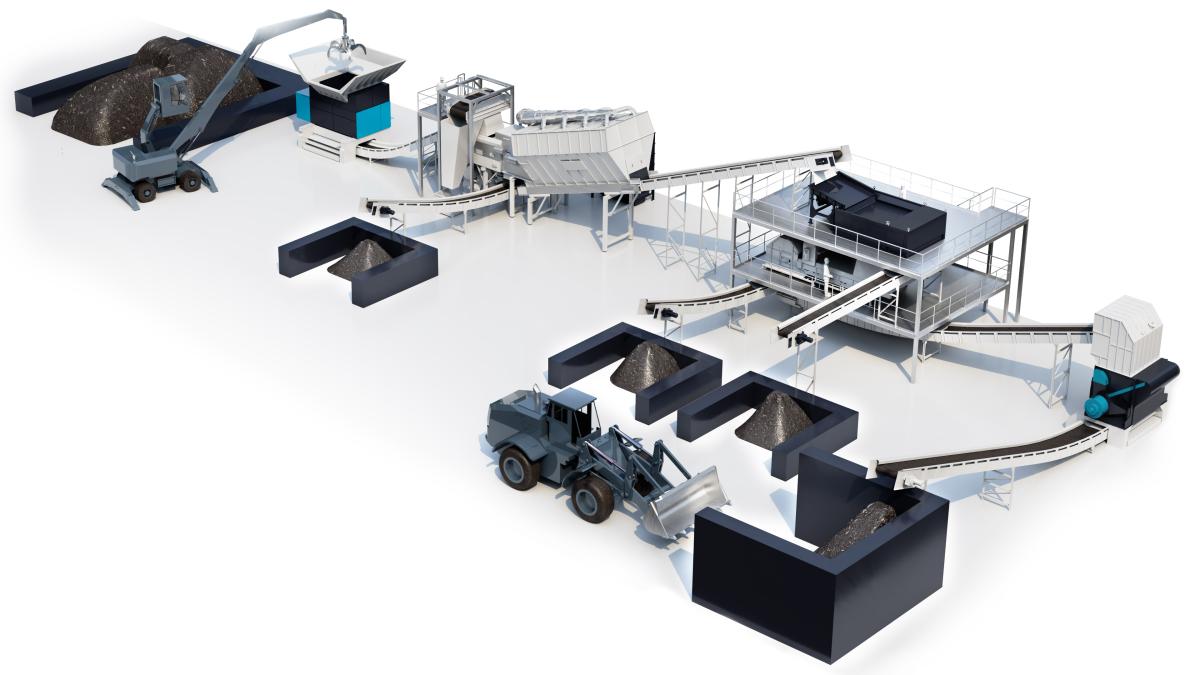

2. Dosing and conveying technology

Well-coordinated processes play a decisive role in the preparation of material recycling. Different conveying and dosing systems are required for energy-efficient and low-wear transportation of input and output materials.

At IFAT 2024 in Munich, we will be presenting several innovations in this field:

VTU – Vecoplan Truck Unloader

Every material recycling process begins with material reception. With the VTU, we offer you a new solution that can be tailored to processes, conveying routes, necessary conveying capacities and conditions.

VDF – Vecoplan Discharge Floor

Optimum material handling plays an important role in the processing of waste. The new bunker system from Vecoplan ensures an even material flow. The intelligent dosing of the material ensures a continuous flow in the downstream processes.

VRF - Vecoplan Pipe Conveyor LIGHT

When developing the new version of the tried and tested "Vecobelt", attention was paid to a lightweight design and cost-optimized production. This variant also guarantees clean and safe bulk goods transportation over long distances. Another advantage is that the VFR light can be installed on existing conveyor bridges.

Optimized process chains ensure a continuous material flow in all system concepts. Vecoplan offers the necessary concepts and units for the smooth interaction of high-performance, coordinated technologies with high availability and cost-effectiveness.

Benefit from the experience gained from numerous projects: Vecoplan has successfully installed many systems for the production of substitute fuels. Complete systems for handling alternative fuels in cement plants, which ensure a continuous feed into production, have also been supplied worldwide.

Vecoplan offers you:

- Technically coordinated products in the areas of size reduction, separation, conveying, dosing and storage

- Detailed engineering

- Comprehensive product experience

- Comprehensive project management

- Assembly, commissioning and extensive service

Conclusion

Visit us at IFAT 2024 and see phenomenal and advanced waste treatment technologies for yourself.

Topics related to environmental compliance, current market developments or the promotion of a sustainable image can be discussed with exhibitors and industry experts in a unique way at the trade fair. As a platform for innovation, IFAT 2024 enables all decision-makers to play an active role in the future of the industry. Companies in the cement and power plant industry, for example, must implement future-oriented technologies and products in order to remain competitive.

A visit to IFAT 2024 is also a must for all those who want to increase their sustainability and assume ecological responsibility. Take advantage of this unique opportunity. If you haven't already done so, request your ticket now: