-

Vecoplan opens a new subsidiary in France

![]()

In recent years, Vecoplan AG has established subsidiaries throughout Europe. These have been closely integrated into the Vecoplan Group in order to bring sales and service even closer to the customer. The company has now set up Vecoplan France to be an even more reliable and stronger partner in France.

-

Vecoplan’s U.S. subsidiary opens a branch in southern California

![]()

Vecoplan LLC in North Carolina, the North American subsidiary of Vecoplan AG, has opened an office with a technology centre in Eastvale, California, under the name "Vecoplan West".

-

Best result in the company's history

![]()

Despite the Corona pandemic, Vecoplan achieves the highest order intake to date, the best result until now and also receives the largest single order ever.

-

Foundation of a subsidiary in Italy

![]()

Vecoplan decides to work the attractive Italian market directly in future and establishes a sales subsidiary with its own service base.

-

Excellent industrial design

![]()

Vecoplan receives the well-known reddot award for a new modern corporate industrial design for the shredding machines

-

Vecoplan celebrates company anniversary

![]()

The company celebrates its 50-year success story together with all its employees

-

Next subsidiary is coming

![]()

Foundation of the PL subsidiary Vecoplan Polska with headquarters in Warsaw

-

Opening of the Technology Center

![]()

The new technology center in Bad Marienberg is the largest and most modern development center in the field of shredding technology in Europe at that time

-

Company founder Irene Scheidweiler is honored

![]()

Irene Scheidweiler receives the the Business Medal of the State of Rhineland-Palatinate

-

Largest project in USA

![]()

Vecoplan realises Conveyor and plant technology in the largest pellet plant in the USA

-

Internationalization - step 3

![]()

Foundation of the ES subsidiary Vecoplan Iberica S.L. with headquarters in Bilbao, Spain

-

The office in Austria also becomes a subsidiary

![]()

Foundation of the AT subsidiary Vecoplan Austria located in Vienna

-

Vecoplan is organized into business units

Organization of Vecoplan into the "Wood" and "Recycling" division.

-

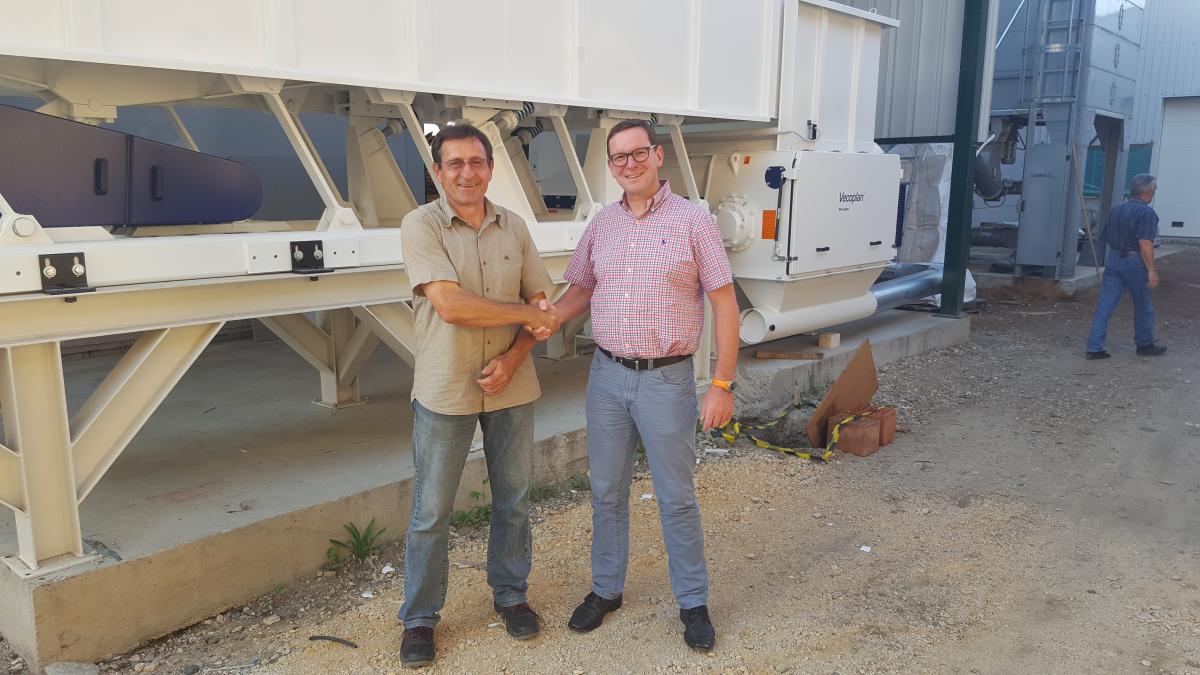

Sales office becomes subsidiary

![]()

![]()

Foundation of the UK subsidiary Vecoplan Limited with registered office in Birmingham

-

Vecoplan becomes AG

![]()

-

The timber market in the USA comes into focus

![]()

Foundation of the US subsidiary Vecoplan Midwest Located in New Albany / Indiana

-

Internationalization - step 1

Opening of the sales office in Great Britain

-

Internationalization - step 1

![]()

Opening of the sales office in Austria

-

Completion of the new production hall with 2,500 m²

![]()

As a result, the company premises cover an area of 24,000 m². With approx. 9,100 m² of production and storage space and 2,500 m² of office space

-

The step across the pond

![]()

Foundation of the US subsidiary Vecoplan LLC with present headquarters in Archdale/North Carolina

-

The sales structure is expanded

![]()

Opening of the first sales office in St. Egidien, Saxony

-

The export share increases to over 50%

Vecoplan is also growing very quickly and very successfully in exports

-

Opening of the first Technical Center

![]()

Here, professional treatment and processing of waste and recyclable materials is demonstrated to visitors under realistic conditions.

-

Sales exceed 50 million for the first time

Exceeding the DM 50 million sales mark (25,6 Mio. €)

-

Vecoplan becomes a subsidiary

With MAX Automation AG, then based in Munich, as the parent company, Vecoplan is gearing up for further successful growth

-

A new company building is built

![]()

Completion of the new and modern administration building on time for the 25th anniversary of the company

-

The administration moves

![]()

After the production also the administration moves to "Eichenstruth"

-

Start of own production

![]()

The first own production plant is built in the industrial area "Eichenstruth"

-

Delivery of the first complete wood recycling plant

![]()

First successes with the design of complete processing installations

-

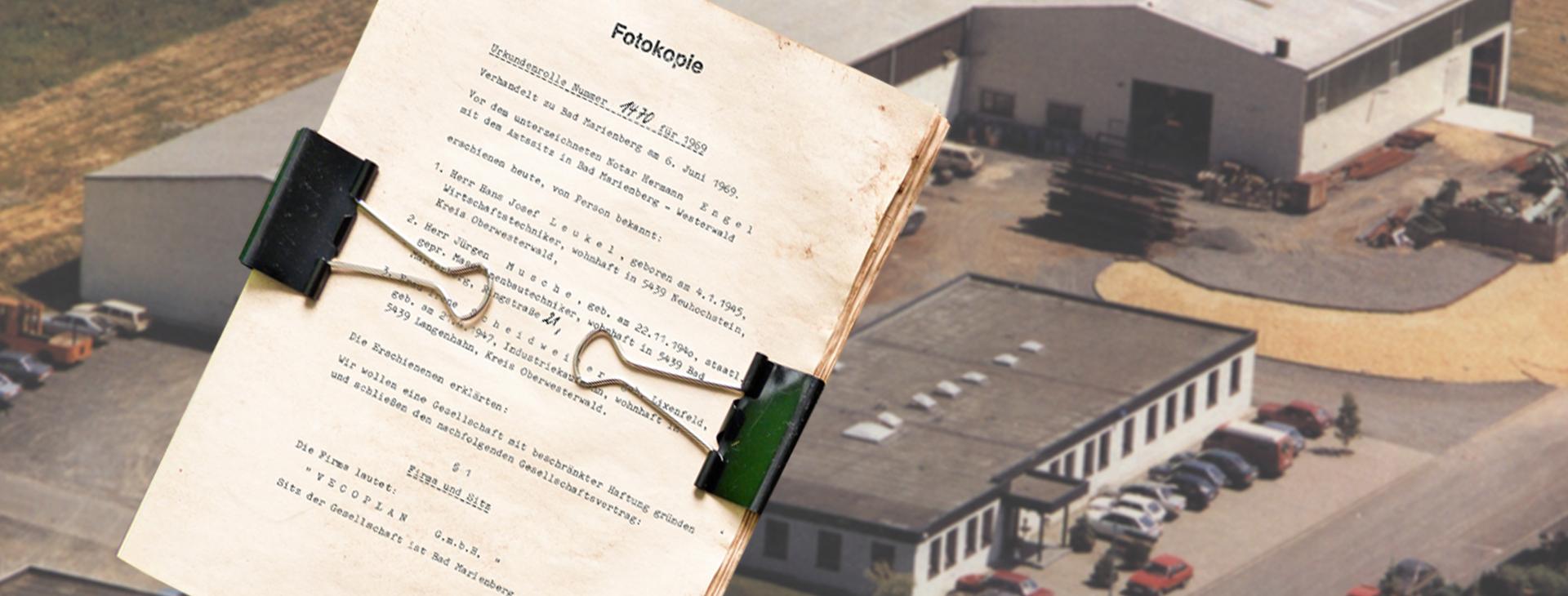

Foundation of the company in Bad Marienberg

Three courageous people from the Westerwald found Vecoplan and deliver the first machines to the regional sawmill and furniture industry

Vecoplan - more than 50 year a success story

Backed by a great deal of entrepreneurial courage, our small company started in 1969 in Germany’s Westerwald region – and this at a time when recycling was not really an issue for the general public. Irene Scheidweiler, who was only 22 years old at the time, founded the Vecoplan company with two colleagues in Bad Marienberg. She could see the potential behind the new recycling industry. Over the years, Vecoplan decisively developed recycling technology and pushed ahead with many innovations. The company has meanwhile registered many patents for new drive concepts and abrasion & shredding technologies. Since 1995, Vecoplan AG has been a subsidiary of MAX Automation SE in Düsseldorf.

2023 - 1969