Requirements

Tschopp Holzindustrie AG has been operating an existing sawmill since 1999, which has long since reached the limits of its capacity. A new sawmill is already in the planning stage. This will triple the wood processing capacity in the future. In the course of this growth, Tschopp needs an efficient solution for the disposal of the waste wood. This is where Vecoplan comes in as a partner for efficient total solutions.

Solution

Tschopp relies on Vecoplan for the processing of waste wood for the production of pellets and the generation of green electricity. Michael Müller, the customer's project manager, and his team supported the Swiss company from the planning stage through to the construction of the new greenfield plant.

Result

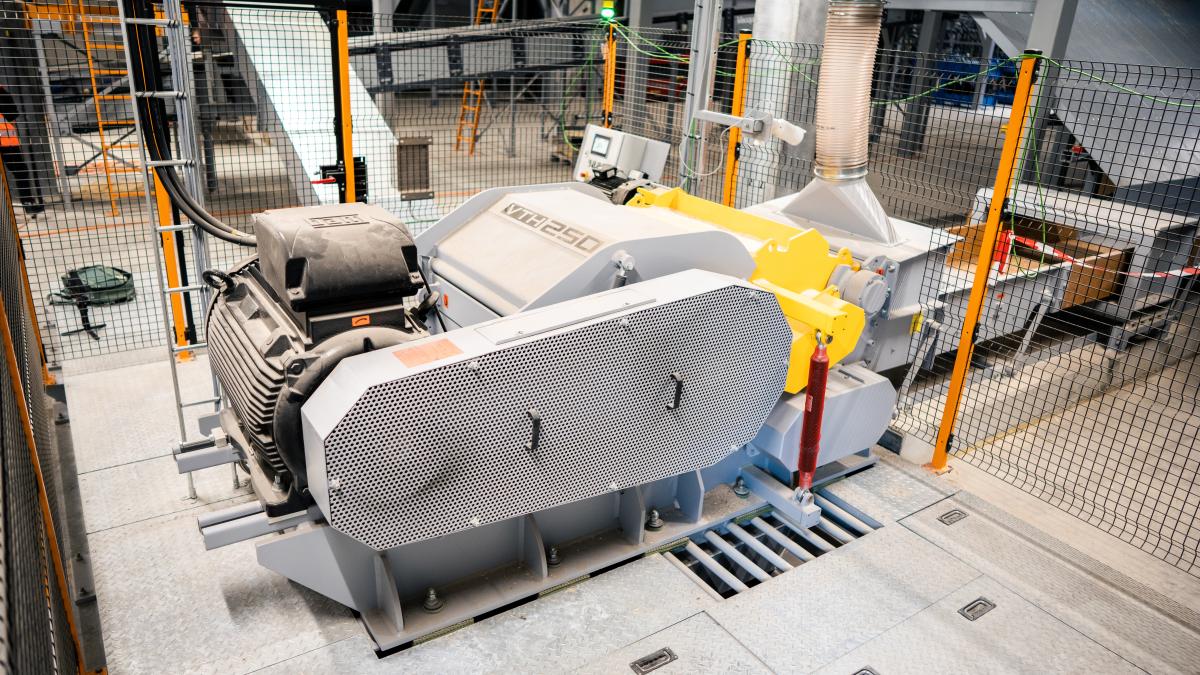

Vecoplan AG supplied a VHZ 1600 series shredder to Switzerland. The pre-shredded pieces are fed horizontally via a Vibration conveyor to the VTH 650 drum chipper. A VRF series tube conveyor was also supplied to transport the processed material to the raw material bays of the pellet plant in a matter of seconds. This means that Tschopp Holzindustrie does not need any intermediate transport for loading. This saves time, space and energy," says Michael Müller.