Requirements

An old-generation VAZ shredder had been working reliably for over 30 years to recycle wood waste for heat generation in the workshop. When the machine started to show signs of wear and tear and the control cabinet recently failed, the electrician recommended investing in a new machine.

Solution

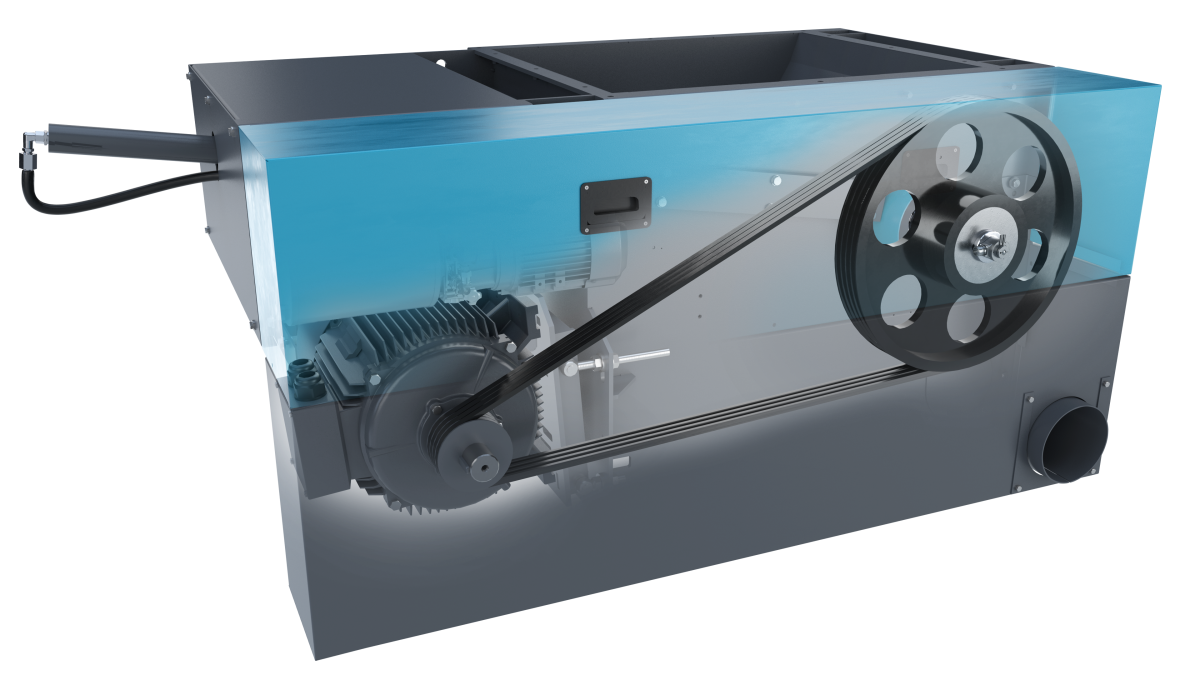

Florian Greb, Area Sales Manager at Vecoplan, supports the Löhr front door workshop: "We advise our customers, plan the technology and work together to find the right solution," he says. Vecoplan offers the VHZ 800 as a suitable solution for joinery and carpentry workshops. The machine is equipped with the energy-efficient and cost-effective VHZ-ESC drive and has been specially developed to meet the needs of the woodworking industry. A test chipping was carried out with the customer in our own technology centre.

Markus Löhr was immediately impressed: “The machine went through the waste wood like butter.”

Result

Vecoplan is supplying a new VHZ 800 with a feed hopper to ensure that residual wood can continue to be shredded for the company's heat production.